Official website

Tel: 0086-18395660720 Email: Caozq@savvyvalves.com

Mobile: 0086-18395660720

Address: Block A Yintai Building, NO.48, North Xianyang Road, Hongqiao, District. Tianjin, China.(Office)

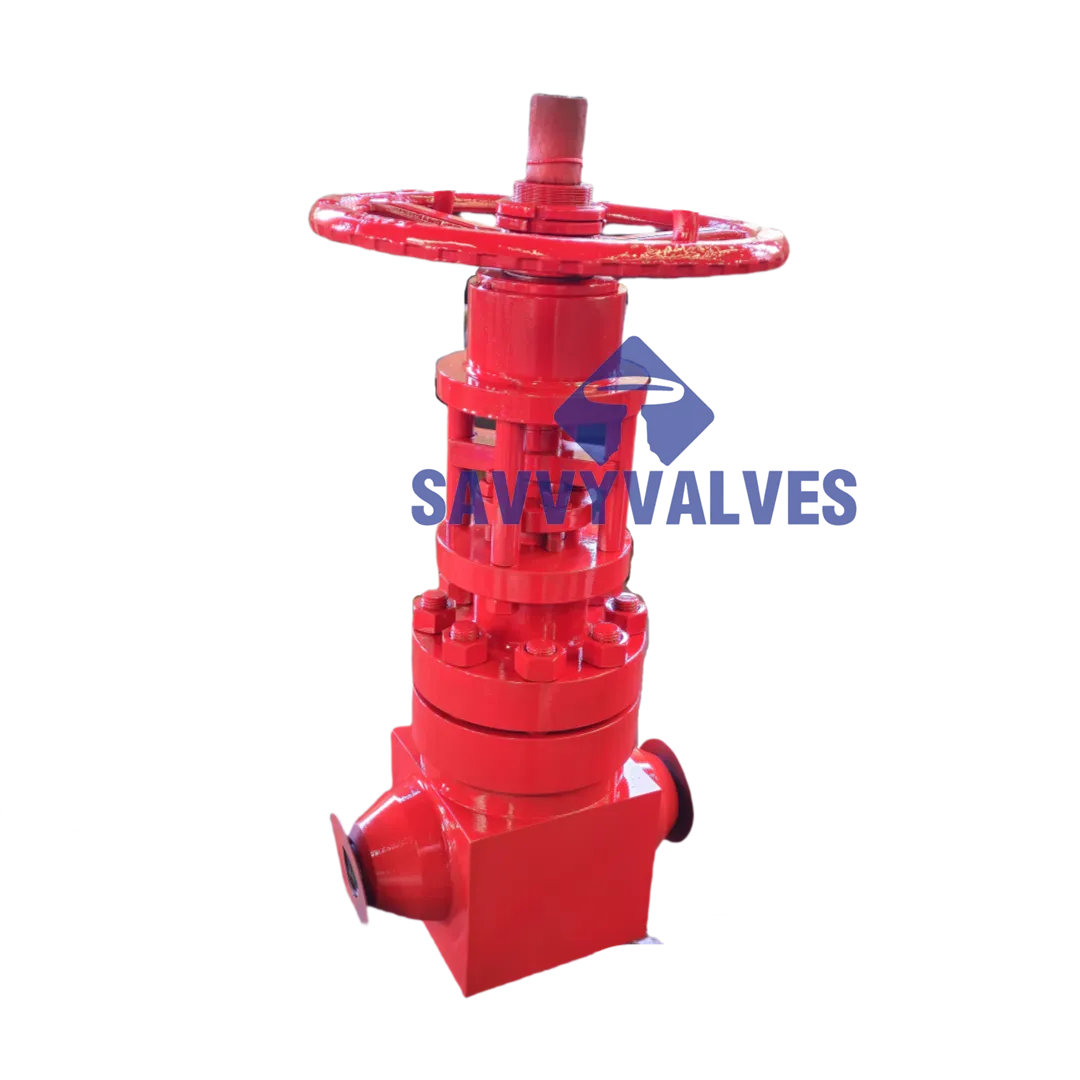

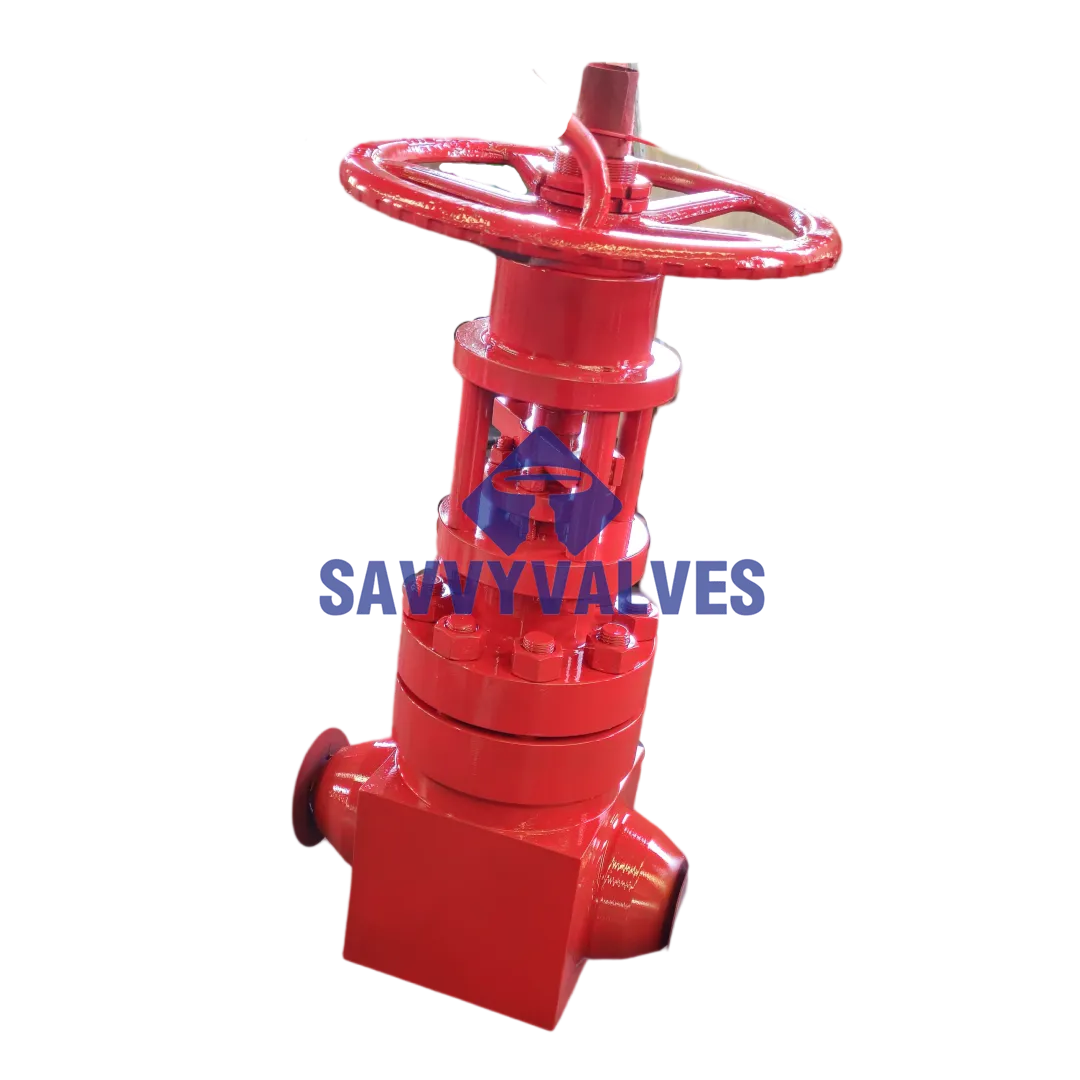

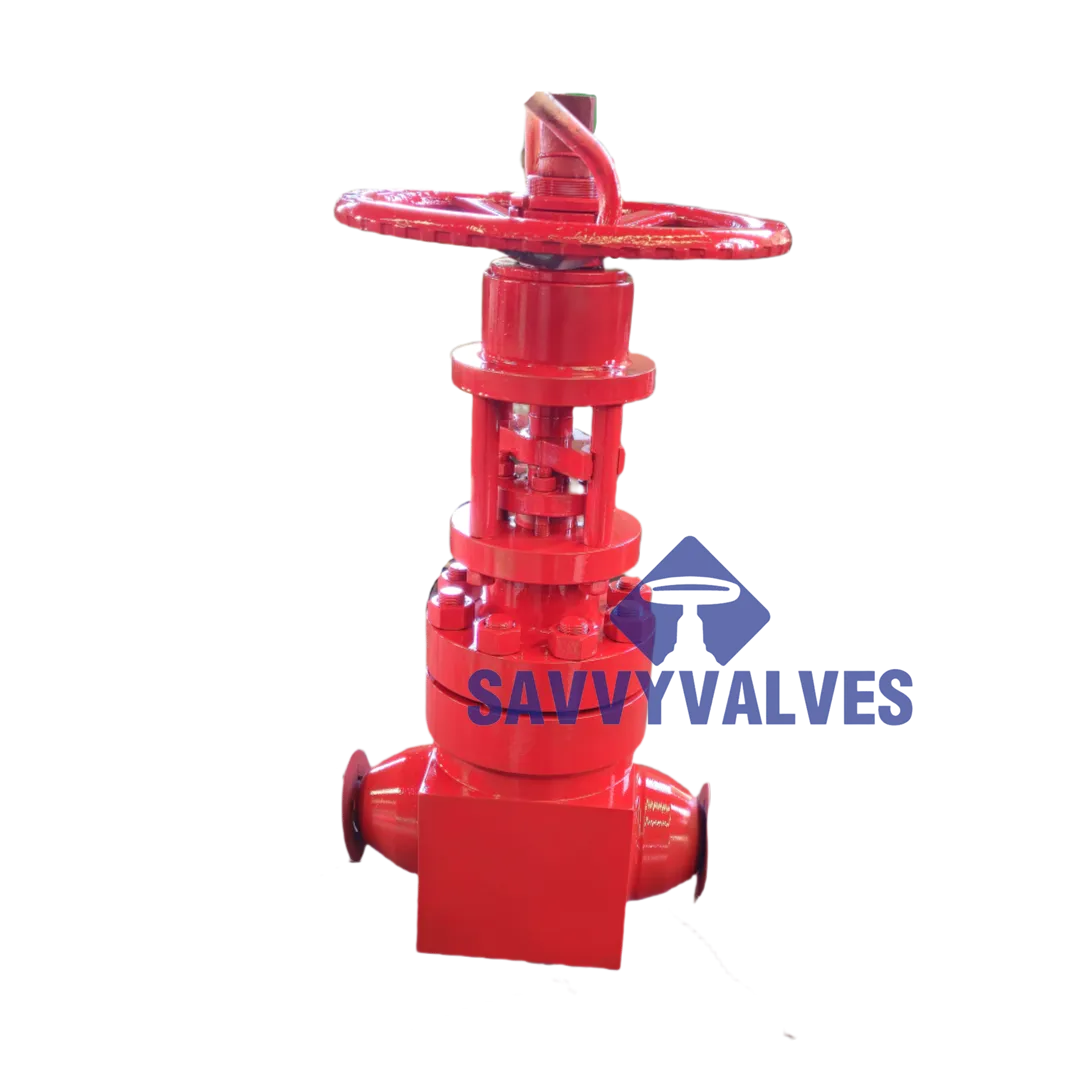

In industries where process temperatures soar and pressures reach extreme levels, specialized control valves are vital for safe and efficient operation. SAVVY 3″ 2500lb Globe Valve Thermal Duty/High temperature solutions play a cornerstone role—servicing sectors from petrochemical refineries and power plants to high-pressure steam pipelines and superheated media transfer stations.

According to Valve Magazine, demand for high temperature globe valves has surged for their robust sealing, precise flow control, and material resilience against thermal cycling.

SAVVY VALVES CO.,LTD. stands at the forefront of global valve manufacturing. With extensive R&D capabilities, strict ISO-compliant quality processes, and a strong commitment to industry innovation, SAVVY consistently delivers advanced valve solutions across critical infrastructure worldwide.

- Specialized in engineered thermal duty and high-temperature valves

- Full range of API, ASME, ANSI, and DIN certified products

- Global project portfolio in oil & gas, chemical, and power sectors

- Strong supply chain and responsive global support

The SAVVY 3″ 2500lb Globe Valve Thermal Duty/High temperature is meticulously designed for ultrahigh temperature, high-pressure service environments.

Brief Product Highlights:

- Size: 3″ (DN80 equivalent)

- Rating: 2500LB (Class 2500, High-pressure)

- Body/Bonnet: ASTM A182 F11 (Cr-Mo alloy steel)

- Disc: ASTM A182 F11 + Stellite 6 hardfacing

- Stem: ASTM A182 F6A

- Body Seat: Stellite 6 overlay

- Operator: Ergonomic handwheel for precision control

- Ends: Butt-Weld (BW) per ANSI B16.25

| Parameter | Specification | Industry Standard | Remarks |

|---|---|---|---|

| Size | 3″ (DN80) | ANSI B16.10 | Compact valve body, standard face-to-face |

| Pressure Class | 2500LB | ASME B16.34 | Class 2500 for high-pressure service |

| Body/Bonnet Material | ASTM A182 F11 | API 602/603 | 1.25% Chromium, 0.5% Molybdenum, High temp resistance |

| Disc | ASTM A182 F11 + Stellite 6 overlay | API 623 | Hardfacing for abrasion/corrosion resistance |

| Stem Material | ASTM A182 F6A | ASME B16.34 | Martensitic stainless, excellent temp strength |

| Body Seat | Stellite 6 overlay | API 623 | Superior sealing even under thermal cycling |

| Operator | Handwheel | ANSI B16.10 | Manual precision flow control |

| End Connection | Butt Weld (BW) | ANSI B16.25 | Welded connection for high integrity |

| Max. Operating Temperature | +600°C (1112°F) | ASME B31.1, B31.3 | Thermal duty, suitable for superheated steam |

| Application Media | Steam, superheated water, hot oil, process gas | API 607 | Wide thermal and pressure envelope |

SAVVY 3″ 2500lb Globe Valve Thermal Duty/High temperature demonstrates outstanding reliability in demanding use cases, including:

- Petrochemical refineries — main steam isolation, high-temperature process lines

- Power generation (thermal & nuclear) — boiler feedwater, superheated steam turbines

- Natural gas processing — hot gas, high-pressure condensate, hydrogen recycling circuits

- Heat transfer oil plants — reliable control for thermal oil at >500°C

- Industrial process steam — sterilization lines, continuous reactors, synthetic fuel plants

Q1: What makes ASTM A182 F11 the preferred material for high-temperature globe valve bodies?

A: ASTM A182 F11 is a Cr-Mo alloy steel with excellent resistance to thermal creep, oxidation, and pressure-induced stress at temperatures up to ~600°C. Its chemical stability prevents embrittlement and scaling, making it superbly suited for thermal duty valves like the SAVVY 3″ 2500lb Globe Valve Thermal Duty/High temperature.

Q2: Why is Stellite 6 overlay preferred for discs and seats?

A: Stellite 6 is a cobalt-based superalloy used for hardfacing due to its exceptional hardness, anti-galling, and corrosion/erosion resistance under cyclic hot service, which is critical for long service life and leak-tight shut-off in high-temp globe valves (ScienceDirect - Stellite Alloys).

Q3: What does the 2500LB pressure rating signify?

A: 2500LB (Class 2500) per ASME B16.34 means the valve is designed to safely operate at pressures up to ~42 MPa (~6000 psi) at room temperature, with derating at higher temperatures as per ASME/EN curves.

Q4: How does BW (Butt Weld) end improve high-temp/high-pressure sealing?

A: Butt Weld ends (per ANSI B16.25) create a full-penetration weld with adjoining pipework, ensuring a leak-free, vibration-resistant, and pressure-integral connection — ideal for severe steam/hot fluid lines.

Q5: What installation standards govern this globe valve?

A: SAVVY globe valves meet ASME B16.10 for face-to-face dimensions, ASME B16.34 for pressure-temp ratings, and ISO/API standards for fire safety, fugitive emission limits, and hydrostatic tests.

Q6: How does the operator (handwheel) design affect performance?

A: Ergonomically engineered handwheels allow precise throttling and safe operation during high differential pressures, with low stem torque for operator safety.

Q7: Are there any certifications or tests relevant for process safety?

A: Yes, valves are hydrotested, shell/seat-leakage tested (per API 598), NDT examined (ultrasonic, PT, RT), and can be delivered with third-party inspection certificates if required.

Global industrial analysis (Grand View Research, 2024) points to accelerated demand for high temperature/high pressure globe valves, driven by:

- Energy transition & decarbonization (hydrogen, biomass, etc.)

- Retrofitting/modernization of aging power/refinery infrastructure

- Advanced material science (creep-resistant alloys, hardfacing overlays)

- Digitization—smart monitoring for predictive maintenance

- Compliance with stricter fugitive emission & safety standards

- Outstanding thermal resistance: Withstand prolonged exposure to +600°C for steam and superheated media

- Superior sealing: Precisely ground Stellite overlays ensure zero-leakage shutoff and minimal seat wear

- Robust construction: Full alloyed body/bonnet and a high modulus stem for long-term reliability

- Customizable trims/configurations: Engineered per project needs—motorized/electro-actuated, NACE conformity, or special linings

- Industry certified: API, ASME, ISO9001 qualified with thorough test documentation

- International engineering team and advanced manufacturing processes

- Rapid delivery and responsive aftersales service

- Customization available for size, rating, operator, material, and accessory packages

- One-stop solution for all high-temperature/high-pressure valve needs

- Dedicated R&D and innovation—ensuring cutting-edge products for evolving industrial requirements.

Tel: 0086-18395660720 | Email: Caozq@savvyvalves.com

[1] “New Materials and Designs make High-Temperature Valves Possible,” Valve Magazine

[2] “Industrial Valves Market – Global Forecast, 2024,” Market Research Future

[3] “Globe Valve Selection for High-Temp Applications,” Engineering Valves Journal

[4] “New Technologies in High-Temperature Valves,” Flow Control Network

[5] “Stellite Alloy Technical Overview,” ScienceDirect