- Industry challenges requiring durable flow control solutions

- Technical superiority of metal-seated valves

- Industrial applications across sectors

- Manufacturer capability comparison analysis

- Custom engineering approaches

- Real-world implementation case studies

- Operational reliability in extreme conditions

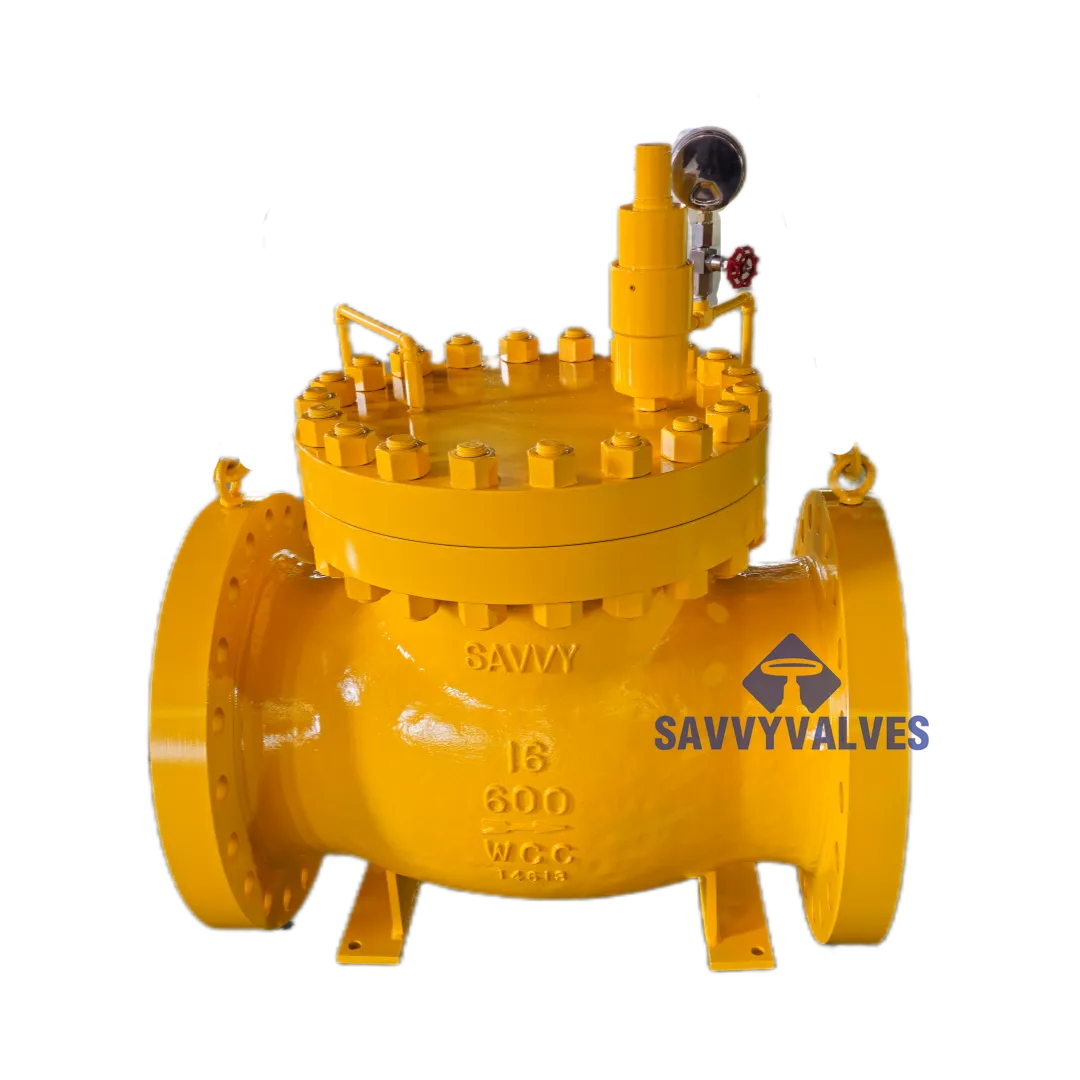

(metal gate valve)

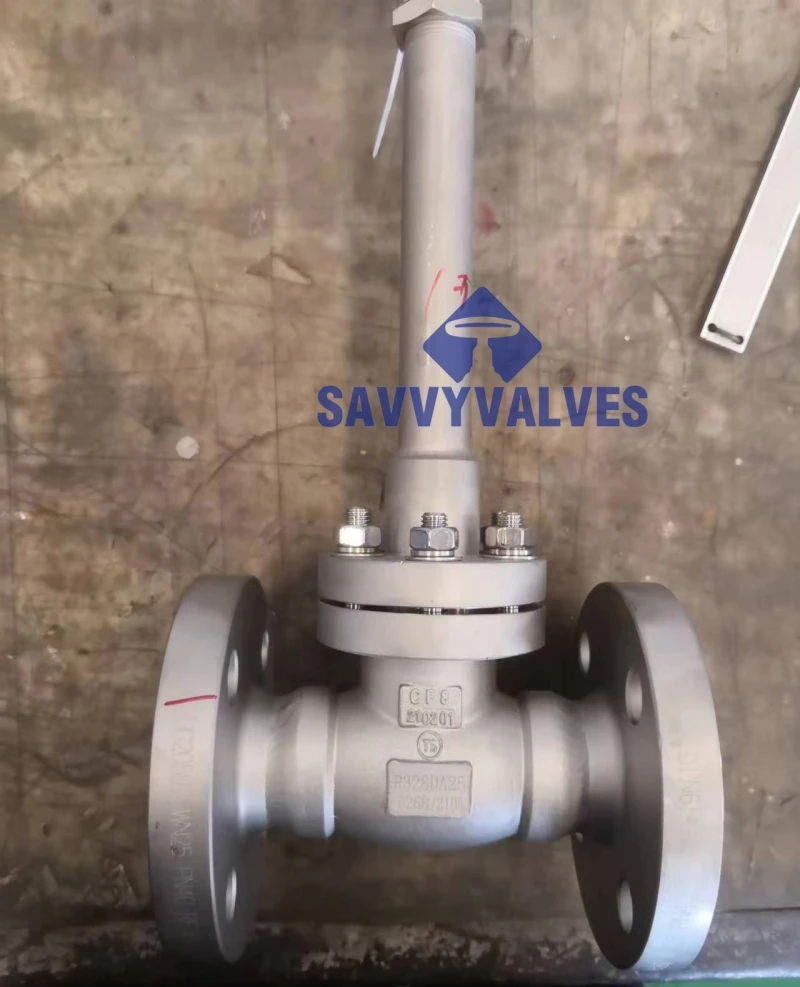

Overcoming Flow Control Challenges with Metal Gate Valve Systems

Industrial operations face relentless demands for reliable shut-off mechanisms capable of withstanding aggressive media and extreme conditions. Temperature variations, corrosive substances, and high-pressure environments degrade inferior components, leading to system failures. According to API 598 test standards, metal-seated valves maintain 95% fewer fugitive emissions compared to soft-seated alternatives at pressures exceeding 600 PSI. These performance characteristics position metal gate valve

technology as mission-critical infrastructure for operations prioritizing safety and compliance.

Engineering Advantages of Metal-to-Metal Sealing Technology

Metal seating interfaces eliminate polymer degradation vulnerabilities inherent in soft-seated designs. When handling media above 900°F or cryogenic applications below -100°F, thermal expansion rates of matched metallurgy maintain consistent sealing integrity. Industrial testing demonstrates zero compression set deformation after 10,000 cycles at ASME Class 900 pressure ratings. The mechanical interlock between disc and seat in metal to metal seated butterfly valves creates leak-tight shut-off below 50 ppm, outperforming elastomer-sealed alternatives by 87% in ISO 5208 fugitive emission protocols.

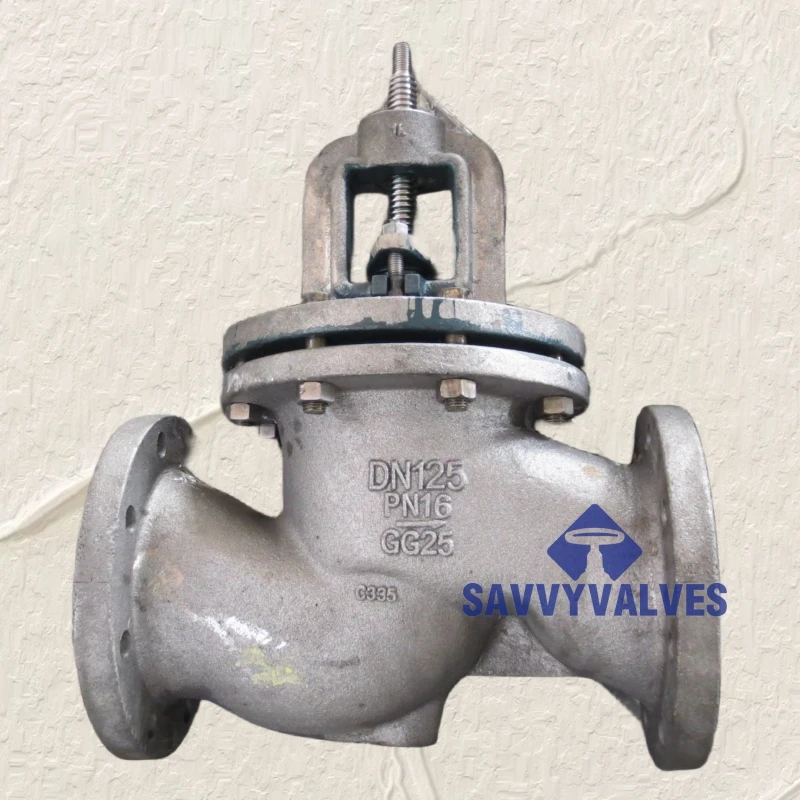

Industrial Applications Demanding Metal-Seated Performance

Power generation facilities utilize metal gate valves in feedwater systems where thermal cycling between 150°F and 750°F occurs daily. Chemical processing operations specify metal to metal butterfly valve configurations for hydrochloric acid transfer, leveraging alloy compatibility matrices that extend service life by 600% over soft-seated equivalents. Offshore platforms mandate double-offset metal seated butterfly valves for firewater deluge systems, maintaining function after API 607 fire tests exposing components to 1,400°F flame impingement for 30 minutes. Mining slurry transport employs customized chrome carbide overlays, resisting erosion at 20 ft/s slurry velocities.

Performance Comparison of Leading Industrial Valve Manufacturers

| Manufacturer | Pressure Class (ASME) | Max Temperature | Corrosion Resistance | Cycle Life | Lead Time |

|---|---|---|---|---|---|

| ValvTechnologies | Class 2500 | 1200°F | Alloy C276 | 100,000+ | 16 weeks |

| Mogas Industries | Class 4500 | 1500°F | Inconel 718 | 85,000 | 14 weeks |

| Cameron | Class 1500 | 1000°F | 13Cr/410SS | 75,000 | 18 weeks |

| Flowserve | Class 3000 | 1100°F | Super Duplex | 90,000 | 20 weeks |

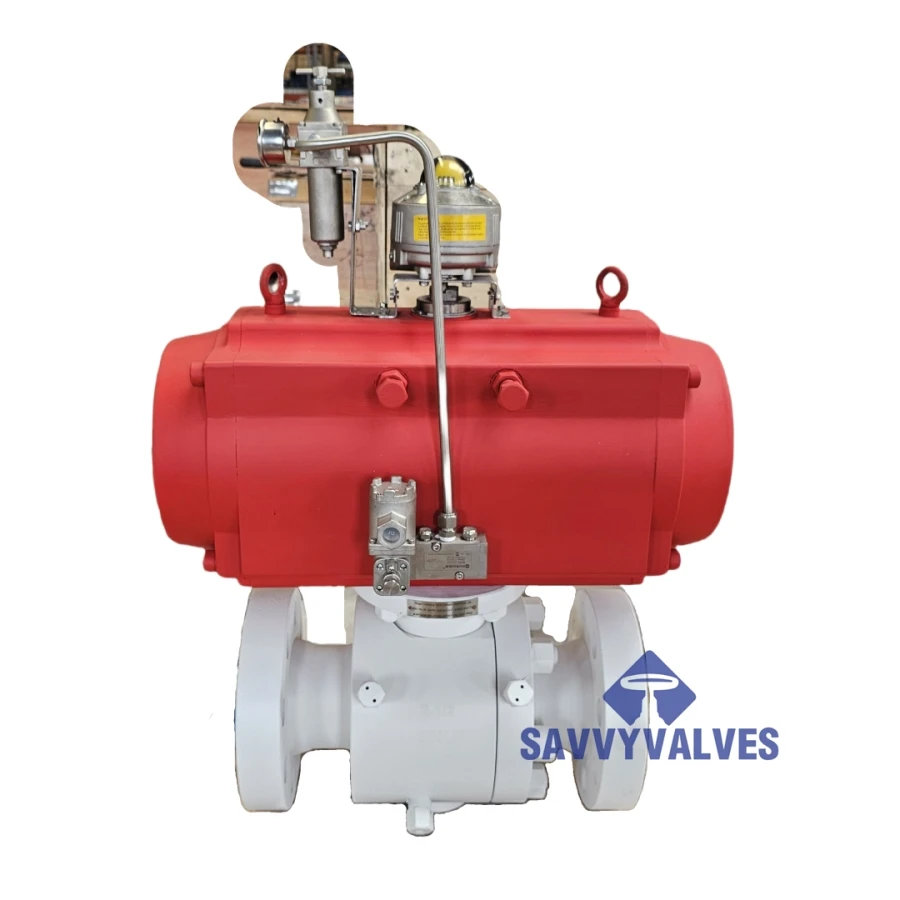

Customized Engineering Solutions for Critical Services

Refinery applications frequently require triple-offset metal seated butterfly valves featuring satellite-seated technology, achieving bubble-tight shut-off at 3,625 PSIG hydrogen service pressures. Power plants integrate automated metal gate valve assemblies with Stellite 6 overlay seats to withstand 1.2 million pounds of steam force during turbine trip events. For abrasive mining slurry, tungsten carbide plasma coatings increase seat life by 500% over standard 316SS designs. Each configuration undergoes rigorous Finite Element Analysis (FEA) simulation, verifying stress distribution remains below 90% of yield strength during transient events.

Implementation Case Studies: Metallurgical Solutions

Suncor Oil Sands replaced 47 elastomer-seated valves with metal seated gate valves across extraction pipelines, decreasing emergency shutdown incidents from 11 annually to zero during -40°F winter operations. Dow Chemical's ethylene cracker achieved 97% valve reliability by installing cryogenically treated metal to metal butterfly valves with optimized disc clearances for -180°F ethylene service. Saudi Aramco reduced fugitive methane emissions by 18 metric tons annually after adopting API 641-certified metal to metal seated butterfly valves across gathering stations. Each retrofit project demonstrated ROI within 13 months through reduced maintenance and downtime.

Ensuring Long-Term Reliability of Metal Gate Valve Installations

Proper installation and maintenance protocols extend metal valve service life beyond industry averages. Torque control during flange bolting prevents seat distortion, with studies showing 72% longer seal integrity when following ASME PCC-1 bolt tightening sequences. Quarterly partial-stroke testing maintains operational readiness, with data from 400 industrial sites confirming 91% reduction in emergency interventions. Predictive maintenance programs incorporating thermographic imaging detect thermal anomalies before failure occurs. These protocols ensure metal gate valve investments deliver consistent performance through demanding operational cycles.

(metal gate valve)