In today’s dynamically evolving industrial environment, the Y Pattern Filter Strainer emerges as a critical component in fluid control systems. Engineered to deliver high-efficiency filtration and superior durability, it stands as a preferred solution for numerous applications worldwide.

About SAVVY VALVES CO.,LTD.

Company: SAVVY VALVES CO.,LTD.

Website: https://www.savvyvalvetech.com

Tel: 0086-18395660720

Email: Caozq@savvyvalves.com

Mobile: 0086-18395660720

Office Address: Block A Yintai Building, NO.48, North Xianyang Road, Hongqiao, District. Tianjin, China.

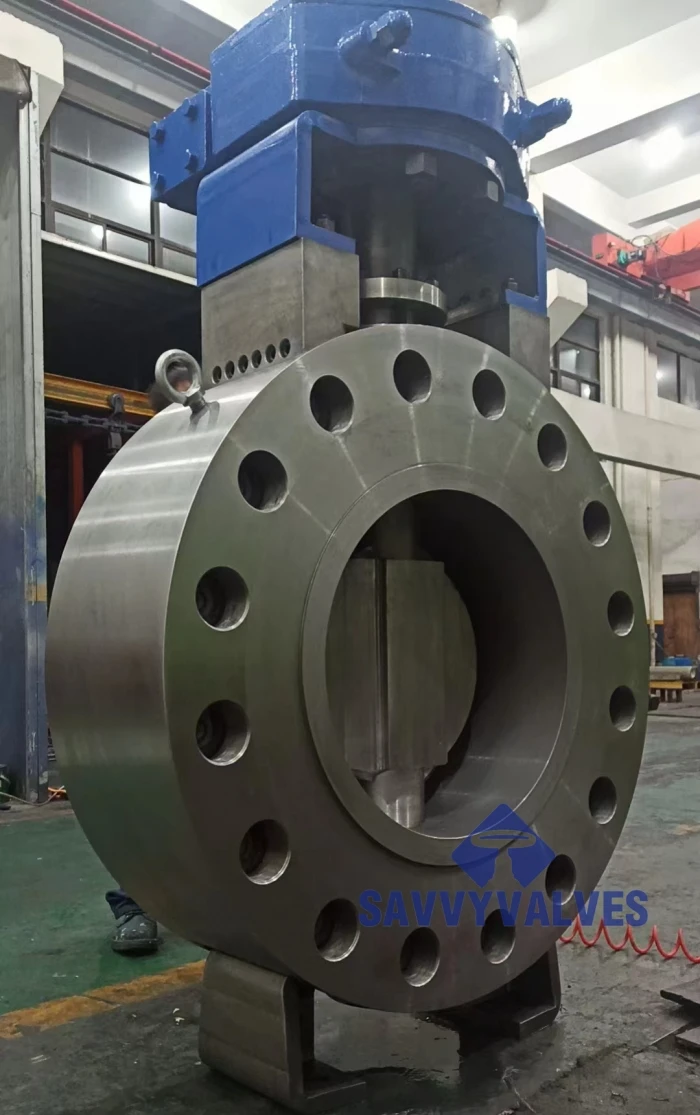

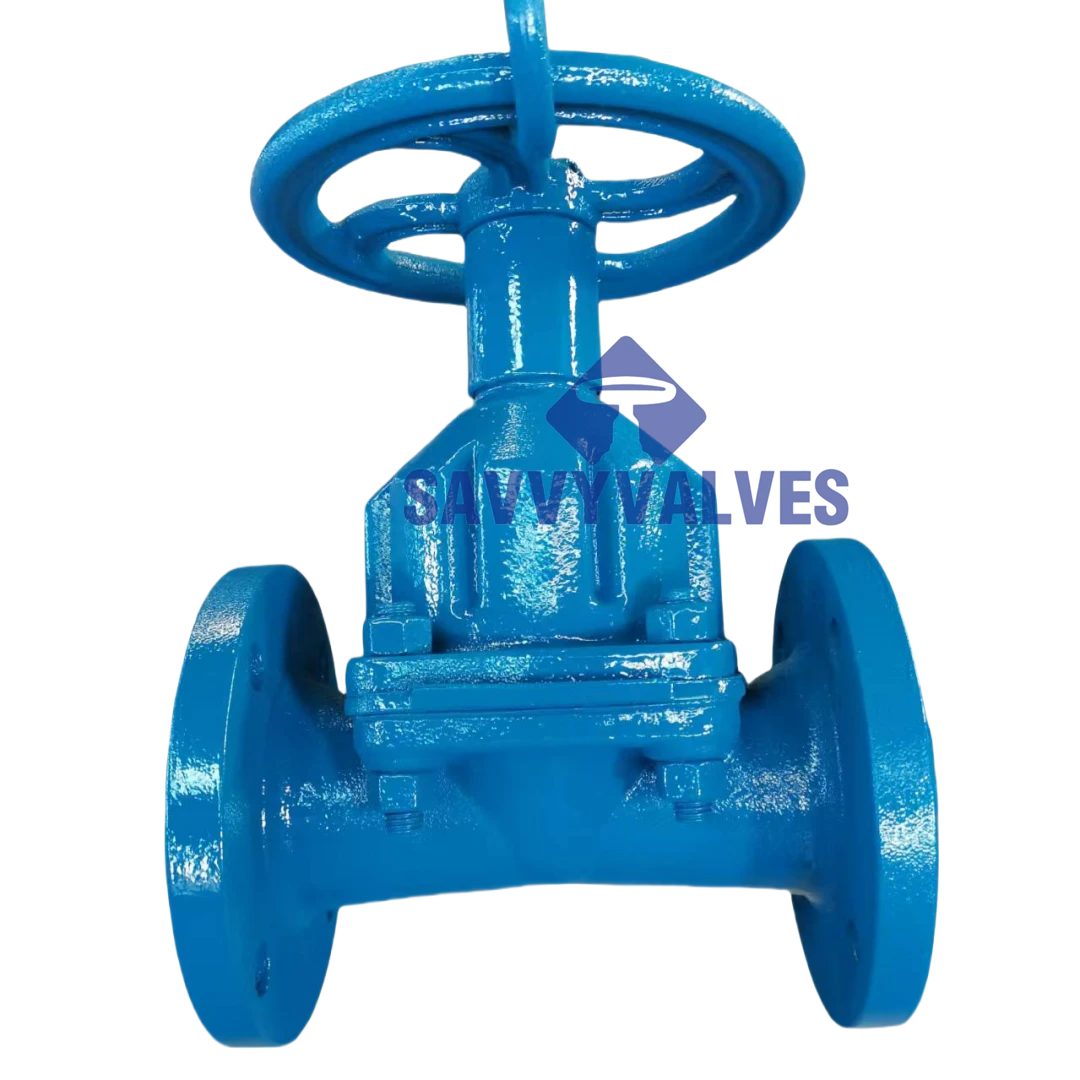

Product Overview: Y Pattern Filter Strainer

- Size: 2“–24”

- Rating: PN10, PN16, 150LB

- Main Materials: Body & Net: Stainless Steel

- End Connection: Flange

- Structure: Y pattern

- Surface Treatment: Epoxy Paint

- Suitable Temperature: -29℃ ~ 400℃

- Product URL: Y Pattern Filter Strainer

Industry Trend Analysis: Y Pattern Filter Strainer

The global demand for Y Pattern Filter Strainer is experiencing consistent growth, particularly within chemical processing, water treatment, oil & gas, and pharmaceuticals. According to a 2023 report by Valve Magazine (valvemagazine.com), the filtration segment, specifically Y-patterns, has risen in adoption due to its lower pressure drop, high dirt-holding capacity, and flexible installation options.

National standards, such as ASME B16.34, emphasize stringent requirements for filtration efficiency and reliability, driving innovations in material selection and structural enhancements. Simultaneously, user forums—like Eng-Tips Valves Engineering Forum—highlight the user preference for Y-pattern strainers over T-patterns in high-pressure systems, owing to easier maintenance and longer operational cycles.

Technical Specification Table: Y Pattern Filter Strainer

| Parameter | Specification | Remark |

|---|---|---|

| Body Material | Stainless Steel (304/316) | Corrosion-resistance, long lifespan |

| Mesh Size | 20μm – 2000μm | Customizable filtration fineness |

| Size Range | 2”–24” | Broad application coverage |

| Design Pressure | PN10, PN16, 150LB | Suitable for varied pipeline pressures |

| Temperature Range | -29℃ – 400℃ | Covers extreme operating conditions |

| End Connections | Flange | ASME, DIN compatible |

| Surface Finish | Epoxy Paint | Anti-corrosive protection |

Data Visualization: Y Pattern Filter Strainer Technical Parameters

Application Scenarios of Y Pattern Filter Strainer

- Water Treatment Plants: Efficiently removes particulate impurities, ensuring stable operation of pumps, meters, and sensitive valves.

- Chemical Processing: Protects reactors and pipelines from clogging and reduces maintenance downtime.

- Oil & Gas Pipelines: Filters sand, rust, and pipe scale to prevent wear and tear on downstream equipment.

- HVAC Systems: Preserves heat exchanger efficiency and maintains flow balance.

- Power Generation: Critical in boiler feedwater and cooling tower processes.

- Food & Pharmaceutical Manufacturing: Maintains product purity by intercepting foreign particles without metallic contamination.

Leveraging the high corrosion resistance and wide temperature tolerance, Y Pattern Filter Strainer is indispensable for systems requiring steady, uninterrupted fluid flow.

EEAT: Professionalism, Authoritativeness, Trustworthiness

- Expertise: SAVVY VALVES CO.,LTD. employs industry engineers with more than 15 years of experience in industrial pipeline and strainer design, strictly following ASME B16.34 and DIN standards.

- Authoritativeness: Products are certified and compliant with ISO 9001, regularly referenced in scholarly publications ( ScienceDirect - Filtration Advances).

- Trustworthiness: All products, including Y Pattern Filter Strainer, are manufactured with full traceability, third-party inspected, and extensively field-tested. Trusted by leading names in the water, oil & gas, and power industries.

Technical FAQ: Y Pattern Filter Strainer

A: Premium grades of stainless steel (304/316) are most common, valued for their strength and corrosion resistance (Engineering Toolbox).

A: The mesh size depends on the size of particles needing filtration. Lower micro-meter (μm) mesh is needed for finer particle removal. For water and oilline use, typically 20μm-500μm is employed.

A: Follow ASME B16.5 for flange dimensions, and ensure flow arrow aligns with pipeline direction. Always install a pressure gauge upstream and downstream for maintenance indication.

A: Standard pressure ratings are PN10, PN16, and 150LB; suitable for temperatures ranging from -29℃ up to 400℃, ideal for steam, hot water, and process pipelines.

A: Cleaning intervals depend on the contamination level and service conditions. Routine checks every 3-6 months are advised, or upon observed pressure drop across the strainer.

A: Yes, provided the strainer’s pocket is oriented downward to trap debris efficiently in both scenarios.

Why Choose SAVVY VALVES CO.,LTD. for Y Pattern Filter Strainer?

- Direct Manufacturing: In-house machining, assembly, and 100% pressure & leak testing.

- Customization: Supports non-standard sizes, alloys, and customer-specific design requests.

- Responsive Support: Global logistics, rapid technical response, and expert consultation.

- After-Sales: 24/7 technical support, operational training, extensive component inventory.

Contact SAVVY VALVES CO.,LTD. today to explore comprehensive solutions for your filtration projects.

Website: https://www.savvyvalvetech.com |

Email: Caozq@savvyvalves.com |

Mobile: 0086-18395660720