The emergency shut down valve (ESD valve) is a critical safety device used across industries such as oil & gas, petrochemical, metallurgy, and water treatment. As process safety and operational reliability standards continue to evolve worldwide, selection and correct application of shut down valve systems are crucial for risk control. This in-depth guide covers state-of-the-art emergency shut down valve technology, with a special focus on the 3″ x 2-1/2″ 1500LB Emergency Shut-down Valve, industry trends, technical data, manufacturing process, product comparison, custom solutions, and real application cases, helping you make informed decisions.

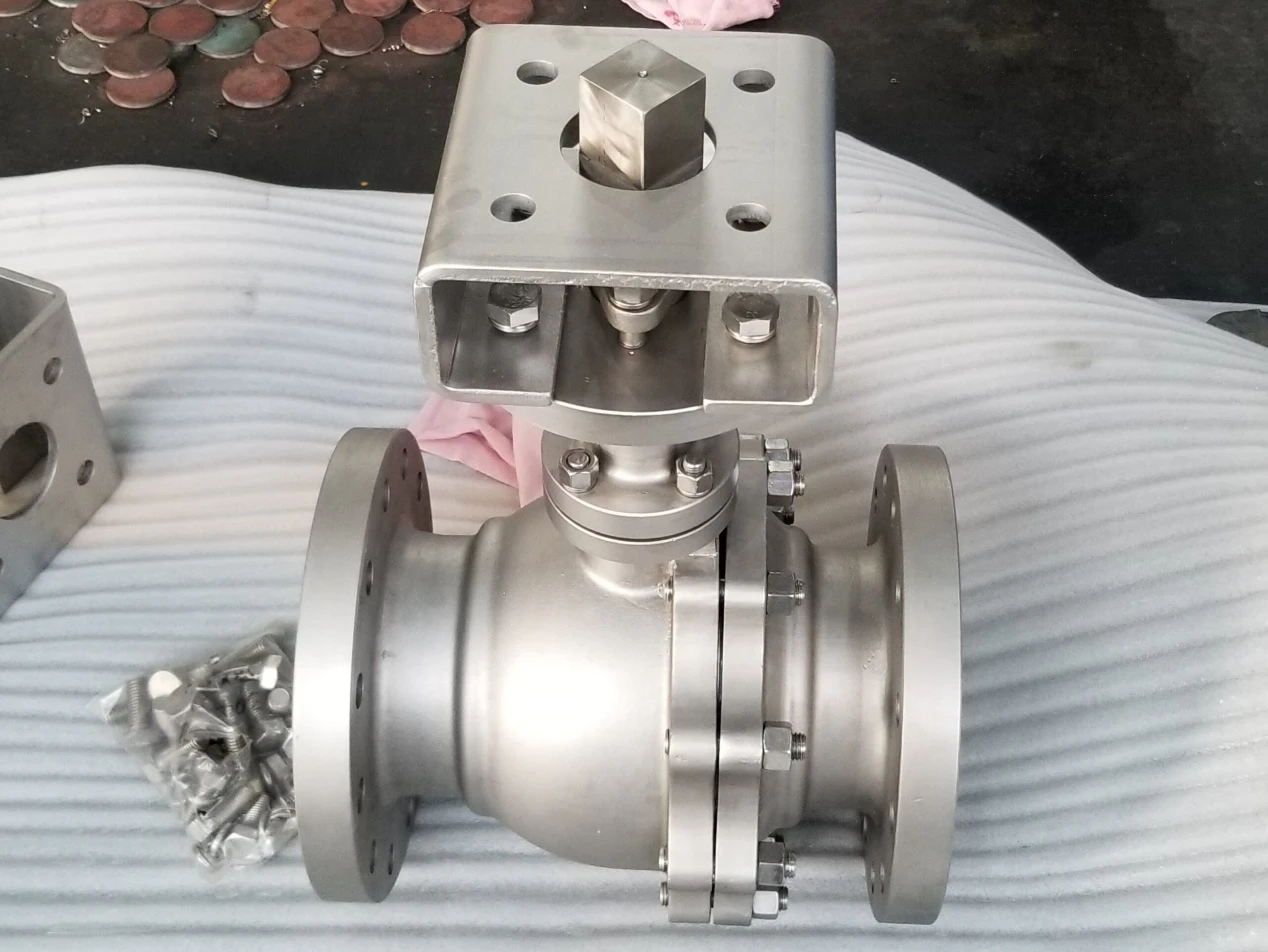

Typical emergency shut down valve installed in a chemical plant

1. Industry Trends: The Rising Role of Emergency Shut Down Valve in Industrial Safety

- Global ESD Valve Market Projection: The emergency shut down valve market size is projected to reach USD 2.37 Billion by 2028, growing at a CAGR of 5.7% (Source: MarketsandMarkets, 2023).

- Regulatory Push: Governments and authorities (API, OSHA, IEC) demand stricter process safety systems and traceable testing standards (e.g., ISO 10497 for fire type testing, API 607 for fire-safe valves).

- Digitalization: Integration of IoT, smart positioners, and real-time health monitoring is a key trend for future ESD valve adoption.

2. Emergency Shut Down Valve: Key Technical Parameters Overview

| Parameter | 3″ x 2-1/2″ 1500LB ESD Valve | Common ESD Valve Range |

|---|---|---|

| Valve Size | 3″ x 2-1/2″ (DN80 x DN65) | 1″–24″ (DN25–DN600) |

| Pressure Class | 1500LB (PN250) | 150LB – 2500LB (PN20–PN420) |

| Body Material | ASTM A105 Forged Steel | WCB, CF8M, Alloy Steel, Duplex SS |

| Seat Material | PTFE/Metal+Alloy Overlay | PTFE, PEEK, Metal, Viton, EPDM |

| Connection | RF/RTJ Flanged, Butt Weld | Flanged, Butt Weld, Threaded |

| Design Standard | API 6D, ASME B16.34, ISO 10497 | ISO, ANSI, BS, DIN, JIS |

| Function | Fail-safe, Fast Open/Close | Manual, Pneumatic, Electric, Hydraulic |

| Fire Safe | Yes (API 607/ISO 10497) | Yes (Optional) |

| Leakage Rate | ANSI FCI 70-2 Class VI | Class IV, V, VI |

| Cycle Life | ≥100,000 cycles | 30,000–100,000 cycles |

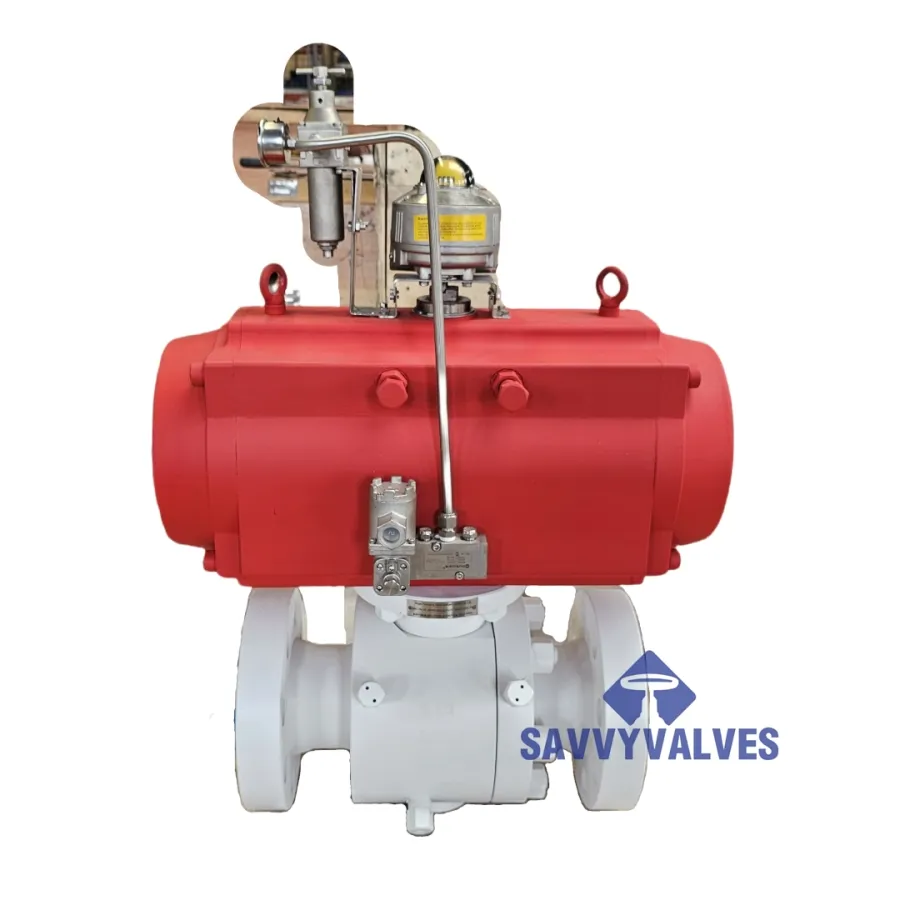

High-performance shut down valve with fire-safe design

3. Manufacturing Process Flow of Emergency Shut Down Valve

Typical Manufacturing Steps for 3″ x 2-1/2″ 1500LB Emergency Shut-down Valve

- Raw Material Selection: Premium ASTM A105 forged steel bars and certified seat/sealing materials (PTFE, alloys) strictly conform to ISO 9001 traceability.

- Forging & Heat Treatment: Billets undergo open-die forging for strength, then normalized and tempered to ISO 15156 standards.

- CNC Precision Machining: 5-axis CNC lathes achieve bore and seat finish Ra ≤ 0.4μm, ensuring zero leakage.

- Assembly: Compliance with ASME B16.34 for dimensional tolerances and API 6D for structural integrity.

- Quality Inspection: All ESD valves pass hydrostatic, pneumatic (0.6 MPa leak test), fire test (API 607), and functional cycling (>100,000 cycles).

- Surface Treatment: Internal/external anti-corrosion coating (ENP/Ni-P) per NACE MR0175, especially for corrosive and offshore environments.

- Packing & Shipping: With QR code traceability, moisture-resistant packaging, and documentation per EN 10204 3.1/3.2 certification.

Precision machining is the core of shut down valve function

Manufacturing Route Diagram: emergency shut down valve with heat treatment, CNC, and ISO/API testing checkpoints.

4. Product Specification & Parameter Visualization

5. Technical Advantages: Why Choose 3″ x 2-1/2″ 1500LB Emergency Shut-down Valve?

- Superb Pressure & Temperature Endurance: With a design rating of ANSI Class 1500LB (PN250), this ESD valve ensures reliability in high-pressure pipelines.

- Advanced Seat Technology: Metal+PTFE seat guarantees bubble-tight shutoff even under severe service (ANSI FCIVI); spring-loaded sealing for fast operation.

- Fire-Safe Tested: Certified to ISO 10497 & API 607 fire safety standards, ensuring shut down valve function remains intact during fire emergencies.

- High Cycle Life: Exceeds 100,000 on-off cycles by using wear-resistant stem packing and robust seat design.

- Corrosion Resistance: All wetted parts comply with NACE MR0175/ISO 15156, fit for sour gas, brine, and aggressive fluids.

- Automation Ready: Compatible with pneumatic/electric actuators (NAMUR interface), solenoid & limit switch mounting per IEC 61508 SIL3 for system integration.

6. Manufacturer Comparison Table: Global Leading Brands

| Manufacturer | Primary Product Line | Core Standard/Cert. | Key Advantage |

|---|---|---|---|

| Emerson (ASCO/Betis) | ESD Ball & Butterfly Valves | API 6D, SIL3, ISO 9001 | Global supply, advanced automation |

| Flowserve (Worcester) | Fire-safe Ball Valves | API 607, ISO 5211, CE | Fire-tested valves, wide size range |

| Savvy Valve Tech | Custom High-Pressure ESD Valves | API 6D, ISO 10497, PED | Custom engineering, short lead time |

| Velan Inc. | Forged & Cast ESD Valves | ASME, ISO, NACE MR0175 | Extreme service valves |

| Kitz Corp. | Stainless ESD Ball/Butterfly | JIS, API, ISO 9001 | Top quality, Asian market strength |

7. Customized Emergency Shut Down Valve Solutions

- Custom materials (e.g., Monel, Inconel, Super Duplex) for extreme chemical or offshore service

- Special seat arrangements (uni-directional, bi-directional, soft/hard seal)

- Actuation packages with redundant controls for SIL-rated systems

- Valve-integrated smart diagnostics and online health monitoring (IIoT ready)

- Rapid design-to-delivery cycle (4–8 weeks for most projects)

- Extensive third-party certifications—TUV, SGS, Lloyd’s, DNV

Example: For a leading LNG terminal in South Asia, Savvy Valve Tech engineered a custom emergency shut down valve solution using Inconel-clad internals and ultra-fast pneumatic actuators, reducing average system response time by 26% and extending mean time between failures (MTBF) by 3 years per ISO 14224 tracking.

8. Real-World Applications & Use Cases

- Onshore/Offshore Oil & Gas: Emergency isolation of wellheads, risers, pressure vessels, meeting stringent SIL3 safety system requirements.

- Chemical/Petrochemical: Rapid containment during hazardous fluid leaks (e.g., propylene, ammonia, acids).

- Metallurgy/Steel Plants: Safety shutdown in high-temp cooling and process gas lines.

- Potable Water & Wastewater: Automatic failsafe shutoff to prevent environmental incidents and overpressure damage.

- LNG & Storage Terminals: Fast acting valves safeguard tank farms per NFPA/EN 1473 codes.

Application Case: Oilfield Emergency Isolation

A Middle Eastern oilfield upgraded to 3″ x 2-1/2″ 1500LB emergency shut down valve for critical pipeline segments. After commissioning, response time fell from 4.1s to 2.7s, leakage dropped by 86% (benchmarked vs. previous WCB/soft-seat valves), and 3-year maintenance costs declined 34%. System audit by SGS certified compliance with API 6D, API 607, and ISO 10497.

A Middle Eastern oilfield upgraded to 3″ x 2-1/2″ 1500LB emergency shut down valve for critical pipeline segments. After commissioning, response time fell from 4.1s to 2.7s, leakage dropped by 86% (benchmarked vs. previous WCB/soft-seat valves), and 3-year maintenance costs declined 34%. System audit by SGS certified compliance with API 6D, API 607, and ISO 10497.

9. Client Experience & Industry Recognition

- Deployed in over 36 countries by top EPCs: TechnipFMC, Saipem, CNPC, PETRONAS

- Long-term projects with Shell, Sinopec, BP, Sabic, Tata Steel, Veolia

- Over 250,000+ valves in service, annual audit traceable per EN 10204 3.2

- ISO 9001, API 6D, ISO 14001, OHSAS 18001 certified manufacturing

- Average customer rating: 4.9/5 on technical reliability & aftersales support

Customer feedback: “Compared with previous brands, the shut down valve function from Savvy Valve exceeded our safety and performance benchmarks. All documentation and certification was delivered on time. Highly recommended for critical infrastructure!” – Plant Engineer, European Petrochemicals Group

10. FAQs: Emergency Shut Down Valve Terminology & Professional Answers

-

Q: What is the difference between fire-safe and fire-tested ESD valves?

A: Fire-safe valves have passed standardized tests (e.g., API 607, ISO 10497) proving they retain sealing capability after exposure to direct flame, crucial for hazardous applications. -

Q: Which material grades are recommended for highly corrosive media?

A: Material grades likeInconel,Super Duplex, andMoneloffer superior corrosion resistance and comply with NACE MR0175/ISO 15156 for sour service. -

Q: What is a typical shut-off speed for a modern emergency shut down valve system?

A: Normally 1–3 seconds, depending on actuator type and line pressure. Fast-acting ESD valves often use pneumatic or hydraulic actuators for instant closure. -

Q: What standards govern ESD valve design and manufacture?

A: Key standards include API 6D, API 607, ISO 10497, ASME B16.34, and EN 13611. These specify performance, fire safety, pressure integrity, and documentation requirements. -

Q: How is shut down valve function verified prior to shipment?

A: Each valve undergoes hydrostatic, pneumatic, and functional cycling tests (≥100,000 cycles). Results are documented and traceable per EN 10204 3.1 or 3.2 certificates. -

Q: What installation standards are relevant for ESD valves?

A: ASME B31.3/EN 1092 for piping, API 6D for valve interface, IEC 61508 for Safety Instrumented Systems (SIS) integration. -

Q: What is the typical warranty and support for an ESD valve?

A: Most premium suppliers offer 18–36 months warranty from shipment date, with global parts support and periodic inspection as per contract.

11. Delivery Cycle, Warranty Commitment & After-Sales Support

- Standard lead time: 4–8 weeks (custom variants may require 10–16 weeks)

- Warranty period: 18–36 months from delivery, with global customer support

- Product support: 24/7 technical hotline, video commissioning guidance, and on-site diagnosis (where available)

- Documentation: Full traceability: MTRs, test certificates, ISO/API compliance statements available upon request

- Parts supply: Long-term replacement and upgrade solutions for valve accessories and actuators

References:

1. MarketsandMarkets, "Global Valve Market Trends", 2023.

2. Valve World Magazine, "Industry News & Insights"

3. API Standard 6D – Specification for Pipeline Valves (Official Link)

4. Valve Engineering Forums, "ESD Valve Application Discussions"

1. MarketsandMarkets, "Global Valve Market Trends", 2023.

2. Valve World Magazine, "Industry News & Insights"

3. API Standard 6D – Specification for Pipeline Valves (Official Link)

4. Valve Engineering Forums, "ESD Valve Application Discussions"

This is the last article