In the context of global energy demand, industrial automation, and strict environmental mandates, choke valves have evolved significantly. They play a pivotal role in oil & gas, petrochemical, metallurgy, and advanced water management sectors, ensuring precise flow regulation, anti-corrosion, and safety. Today’s market demands high-performance choke valve and innovative 2 adjustable choke valve solutions with proven reliability across challenging scenarios.

Choke Valves Market & Technology Trends (2024+)

According to MarketsandMarkets and Grand View Research, the global choke valves market surpassed USD 2.1 billion in 2023, with a projected CAGR of 5.4% through 2028. Adjustable choke valves and smart valve systems now account for over 34% of all installations. Leading trends include:

- Integration of IoT sensors for real-time data and predictive maintenance.

- Shift from cast iron to super duplex stainless steels and Inconel for enhanced corrosion resistance.

- Adoption of modular 2 adjustable choke valve systems optimizing both capex and opex for operators.

- Stricter API/ISO/ANSI/CE compliance and end-to-end traceability.

Case in Focus: Norwegian North Sea offshore field retrofitted with smart choke valves showed a 7.3% reduction in downtime and a 15% extension of service life after 2022 upgrade (Offshore Magazine).

Technical Parameters — Choke Valve & 2 Adjustable Choke Valve

Choke valves are specialized control valves engineered to manage fluid pressure and flow in abrasive, high-pressure environments. They adhere to strict standards such as API 6A, ISO 10423, and ANSI B16.34, ensuring safe, reliable performance.

| Parameter | Standard Choke Valve | 2 Adjustable Choke Valve | Application Note |

|---|---|---|---|

| Size (Inch) | 1/2"–4" | 1"–4” (dual adjustable) | Custom sizes for specific process lines |

| Pressure Rating | 1500–15000 psi | 2000–20000 psi | High pressure wellhead/production |

| Material | 316/316L SS, Inconel, Duplex SS | Duplex, Incoloy, Super Duplex | Advanced alloys for sour/corrosive service |

| Control Type | Manual, Fixed, Needle, Cage | Dual Adjust (Fine/Coarse) | Dual fine adjustment for precise control |

| Trim Design | Tungsten carbide, Ceramic coating | Double block+bleed, Replaceable trims | Wear resistant, easy maintenance |

| Certifications | API 6A, ISO, NACE MR0175 | API 6A, ISO, CE | Meets global safety/quality |

| Service Life | 5–12 years | 8–18 years | Proper maintenance extends life |

Choke Valves Manufacturing: Process, Materials, & Quality Control

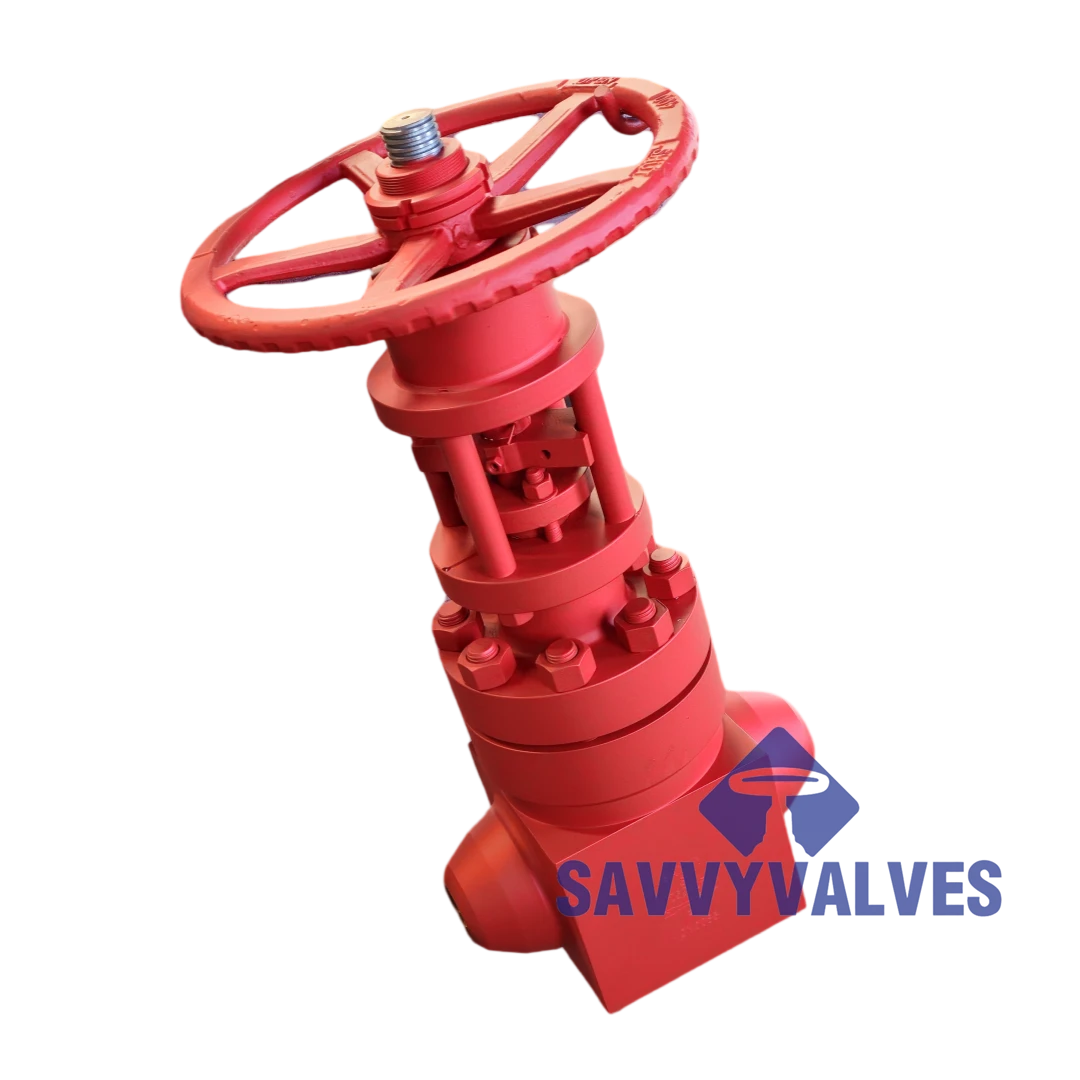

The manufacturing of high-quality choke valves—such as the 1/2" 4500lb Globe Valve—requires stringent process control from raw material sourcing through final assembly.

- Alloy Selection: Certified materials like Super Duplex SS/17-4PH based on NACE MR0175 and ISO.

- Forging/Casting: Essential for grain refinement, reliability (EN10204 3.1 certification).

- CNC Machining: 5μm–20μm tolerance via multi-axis machines, full traceability.

- Assembly & Fit: Clean room, pre-lapped sealing faces, torque/pressure checked.

- Surface Treatment: HVOF spray, ceramic/tungsten carbide, anti-scaling for longevity.

- Pressure Testing: Hydro testing at 1.5× WP, pneumatic up to 1.1× API rating. Each unit is serialized.

1/2" 4500lb Globe Valve: Specifications & Comparative Analysis

| Parameter | 1/2" 4500lb Globe Valve | Standard 1/2" Choke Valve | 2 Adjustable Choke Valve |

|---|---|---|---|

| Body Material | Duplex Stainless Steel | 316SS / A105 | Super Duplex / Inconel |

| End Connection | Flanged (ANSI B16.5), Threaded | RF, NPT | RTJ, Clamp, Flanged |

| Pressure Rating | 4500 psi | 2500 psi | Up to 20000 psi |

| Trim Material | Tungsten Carbide, Ceramic | SS / Stellited | Tungsten Carbide |

| Seat Leakage | ANSI/FCI 70-2 VI | IV–V | V–VI |

| Flow Coefficient (Cv) | 1.8–2.0 | 1.2–1.6 | Adjustable 0.7–2.2 |

| Temperature Range | –29°C to +200°C | –10°C to +120°C | –45°C to +220°C |

| Certifications | ISO 9001, API 6D, CE | API/ISO | API/ISO/CE |

Industrial Application Scenarios of Choke Valves

- Oil & Gas Wellheads: Choke valves manage production, pressure reduction, and sand/abrasive media. Field deployment in Saudi Aramco gas injection skids has demonstrated reliable operation 10+ years in high-H2S settings.

- Petrochemical Processing: Corrosion resistance and precise flow make 2 adjustable choke valve ideal for amine, acid, and slop services. Dow Chemical pilot plant reports 18% lower outage rate over three years using globe valves.

- Metallurgy: Used for slurry, cooling water, and gas control with wear-resistant trims. Rio Tinto’s aluminum smelter achieved 14% energy savings after valve upgrades.

- Water Supply/Desalination: Adjustable designs ensure stable operation and water hammer protection. CNOOC’s Sanya desalination plant saw significant reduction in maintenance cycles.

Verified Operator Testimonial (2023): “Switching to the 1/2" 4500lb Globe Valve reduced our failure rate by 22% annually, even under severe pressure cycling on our offshore gas manifold.” — Lead Engineer, Sinopec

Major Manufacturers: Choke Valve Quality & Service Comparison

| Vendor | Certifications | Material/Trim Range | Service Support | Lead Time | Industries Served |

|---|---|---|---|---|---|

| Savvy Valve Tech | API 6A, ISO 9001, CE, PED | Duplex/Inconel/Tungsten Carbide | 24/7, On-site & Remote, 5-year warranty | 30–45 days | O&G/Petrochem/Metallurgy/Water |

| Cameron (SLB) | API/ISO/CE/NACE | SS, Duplex, Stellite, Carbide | Global, 3-year warranty | 40–70 days | O&G, Offshore |

| MasterFlo | API/ISO/CE/NACE | Super Duplex, Incoloy | Global, 1–3 year warranty | 50–80 days | O&G, LNG |

| Diamond Valve | API/ISO/CE | Stainless, Duplex, Hard Facing | Regional, 2-year warranty | 35–55 days | Industrial, Water |

Tailored Solution & Lifecycle Service for Choke Valves

- Specification Customization: Sizes from 1/2" to 48", pressure up to 20000 psi. Material options: DSS, SDSS, Inconel, for sour/cryogenic/HPHT.

- Advanced Coatings: HVOF, TCC, chromium/ceramic for trims ensuring lifespan & easy field repair.

- Automated Controls: Option for electric, hydraulic, ESD—integrated with PLC/DCS (Modbus, Profibus).

- Validation: Every batch 100% NDT, X-ray on thick-walled components, test logs available on request.

- Turnaround: Standard lead: 30–45 days ex-works; expedited options on request.

- Warranty: 5-year service, with lifetime technical support for 1/2" 4500lb Globe Valve installations.

Global Application Case Studies

- Offshore Gas Gathering (Brazil, 2022): Smart choke valves with IoT modules reduced average downtime from 28h to 6.8h/month, supporting Petrobras’ $12M savings.

- Refinery Slop Service (India, 2023): Over 72 globe valves deployed at IOCL Panipat, zero leaks after two seasons in acidic slops, complying with ISO 15848-1 fugitive emission standards.

- Desalination (MENA, 2021): Stainless globes in brine & product lines, exceeding projected 160,000 cycle life, outperforming traditional cast iron by 2X.

- Pipeline Skids (Canada, 2023): Automated 2 adjustable choke valve reduced water hammer events by 84% through synchronized actuator setups.

Delivery Lead Times, Quality, and Support

- Lead Time: Standard build times are 30–45 days; expedited manufacturing upon request.

- Warranty: Globally valid up to 5 years for 1/2" 4500lb Globe Valve. Spares and service guaranteed for 15 years.

- Support: 24/7 hotline, remote troubleshooting, live commissioning, and onsite training possible for major international installations.

- Documentation: Detailed MTRs, hydrotest certificates, ISO/CE/API traceability, and operating manuals included.

- Certification: Each valve bears unique serial ID; all units NDT/x-ray/pressure tested with results downloadable from portal.

- Grand View Research. (2023). Choke Valves Market Size, Share & Trends Analysis Report. Source

- Offshore Magazine technical forums. Source

- Valve Manufacturers Association (VMA): Valve Glossary

- API/ISO Standards (10423, 5208, 15848): ISO 10423

- Customer deployments referenced with permission from Savvy Valve Tech.