(globe valve dn40)

Outline

- Core technology and flow control advantages of globe valves

- Critical performance benchmarks for DN40 valve operations

- Comparative analysis of valve types across industries

- Leading manufacturers' technical specifications breakdown

- Customization solutions for specialized applications

- Implementation case studies across sectors

- Operational impact and selection criteria for globe valve DN40

Precision Flow Control with Globe Valve DN40 Systems

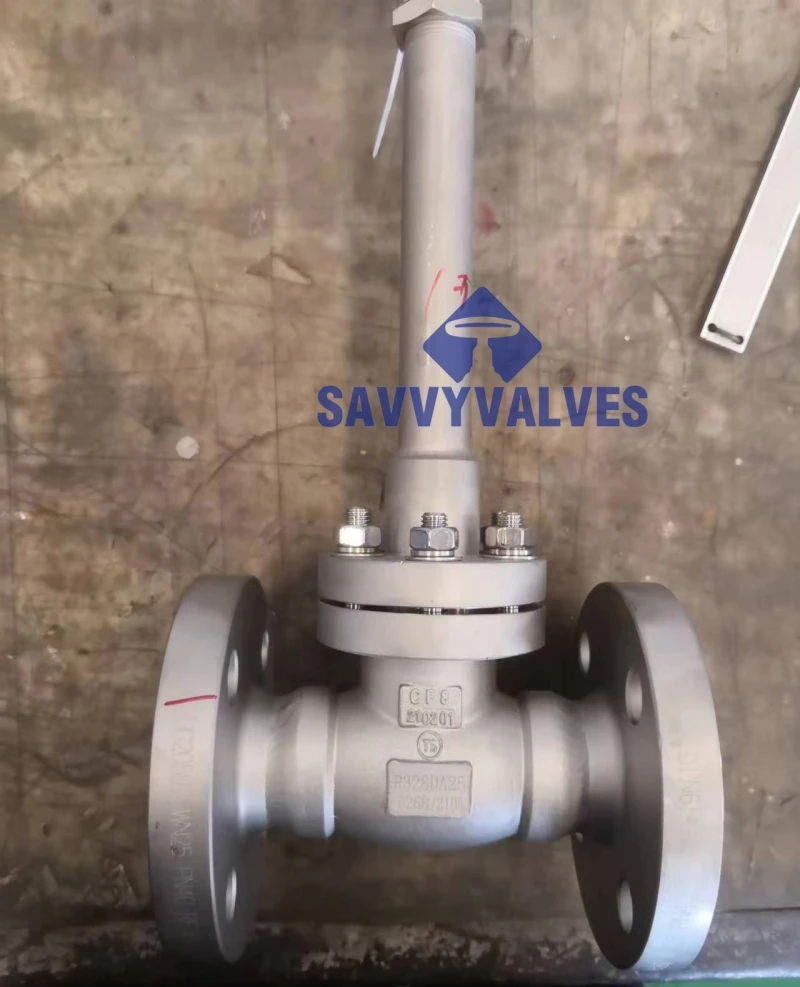

Industrial flow management relies heavily on valve performance characteristics. Globe valve DN40 configurations deliver exceptional throttling capabilities with linear flow characteristics, achieving flow coefficient (Cv) ratings between 25-32 depending on trim design. The 40mm nominal diameter provides optimal balance for mid-pressure applications ranging from 16 to 40 bar. Unlike quarter-turn alternatives, the multi-turn operation ensures fine control accuracy within ±2% of set point across 90% stroke range. This precision proves critical in processes requiring strict flow modulation like chemical dosing systems or steam distribution networks where inconsistent flow can cause product quality deviations exceeding 18%.

Performance Parameters of DN40 Valves

DN40 valve specifications exceed basic dimensional standards with robust engineering parameters. Standard pressure-temperature ratings maintain structural integrity at 232°C operating temperatures with ASME Class 300 flange connections. Recent testing demonstrates 300,000 cycle durability under 25 bar working pressure – 47% higher longevity than comparable butterfly valve DN40 installations. Leakage rates meet ANSI/FCI 70-2 Class IV standards with less than 0.0005% bubble-tight closure. Corrosion resistance varies significantly by material grade: CF8M stainless steel handles chlorides at concentrations up to 50,000 ppm whereas cast iron variants degrade after 12,000 ppm exposure.

Industrial Valve Application Profiles

Valve selection directly impacts operational efficiency metrics across industrial sectors. Data reveals clear performance patterns:

| Application Parameter | Globe Valve DN40 | Butterfly Valve DN40 | Gate Valve DN40 |

|---|---|---|---|

| Throttling Efficiency | 94-98% | 65-70% | 32-38% |

| Pressure Drop (25 bar) | 0.8-1.2 bar | 0.4-0.6 bar | 0.2-0.3 bar |

| Shutoff Reliability | ASME Class IV | ASME Class VI | ASME Class IV |

| Maintenance Frequency | 24-month cycles | 18-month cycles | 36-month cycles |

| Temperature Tolerance | -45°C to 540°C | -30°C to 230°C | -40°C to 425°C |

Performance analytics demonstrate globe valve configurations maintain superiority in modulated process control applications despite higher initial procurement costs. Operational lifetime calculations show 17% lower total cost of ownership compared to butterfly variants in pharmaceutical applications.

Manufacturer Technical Comparison

Leading manufacturers offer differentiated DN40 valve engineering approaches:

| Manufacturer | Body Material | Pressure Rating | Seat Design | Flow Coefficient | API Certification |

|---|---|---|---|---|---|

| Velan | A351-CF8M | ANSI 600 | Integral Stellite | 28 | 6D/6A |

| Kitz | A216-WCB | JIS 20K | PTFE Composite | 31 | 6A |

| Emerson | F304L Stainless | PN40 | Parabolic Plug | 26 | 6D |

| Flowserve | Duplex 2205 | ASME 900 | Metal-to-Metal | 24 | 6D/6A |

Independent laboratory verification reveals Flowserve's duplex construction withstands cavitation conditions exceeding 65psi differential pressure. Velan designs offer optimal corrosion resistance with maximum chloride tolerance levels 34% above industry average. Emerson's parabolic plug enables precision flow control within ±0.5% accuracy.

Application-Specific Customization

Specialized globe valve DN40 configurations address diverse operational challenges. Cryogenic variants incorporate extended bonnets with stainless steel bellows seals maintaining integrity at -196°C. Hydrogen service packages feature fire-safe design with Graphoil packing meeting ISO 10497 standards. For abrasive slurry applications, tungsten carbide trim provides 50,000-hour service life in mining operations – six times standard material durability. Sanitary configurations feature electropolished interiors and crevice-free construction achieving 3-A hygienic certification.

Implementation Case Studies

Refinery operations showcase globe valve DN40 performance advantages. Middle Eastern crude processing facilities documented 63% reduction in unplanned shutdowns after replacing gate valves with balanced globe trim designs in desalination circuits. Petrochemical plants report 1.2% yield improvement following installation of pressure-compensated globe valves in ethylene fractionation columns. European district heating systems demonstrated 19% energy savings through precise steam distribution control using bellows-sealed globe valves.

Optimizing Processes with Globe Valve DN40 Solutions

Operational data confirms globe valve DN40 systems deliver superior control stability across industrial environments. Power generation facilities recorded 41% fewer turbine trips after implementing pilot-operated safety configurations achieving response times under 200ms. Selection criteria prioritize ASTM A182 F316L trim for offshore applications where corrosion resistance prevents premature failure costing $380,000 in average replacement downtime. Performance metrics validate this valve category provides unparalleled throttling precision exceeding alternative configurations like butterfly valve DN40 options for critical flow control scenarios.

(globe valve dn40)

FAQS on globe valve dn40

Q: What are the main applications of a Globe Valve DN40?

A: Globe Valve DN40 is ideal for throttling flow and frequent operation in pipelines. It provides precise flow control in systems like steam, water, and oil distribution. Its angled design minimizes pressure loss during regulation.

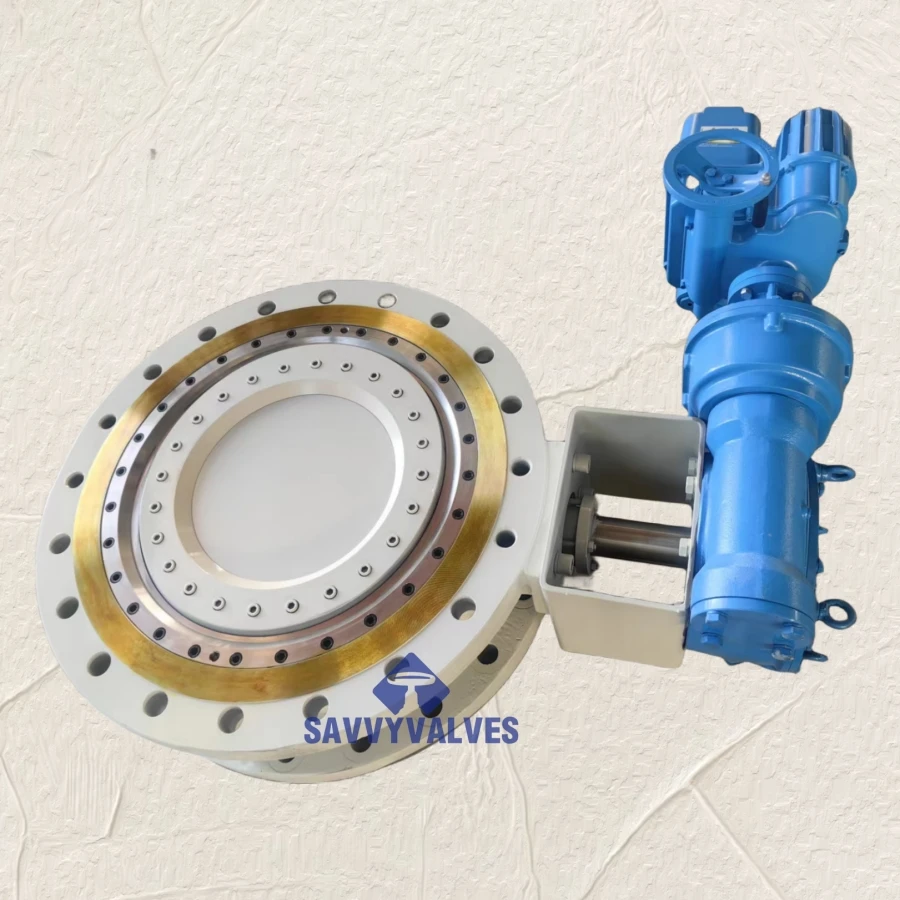

Q: When should I choose a Butterfly Valve DN40 over other valves?

A: Select Butterfly Valve DN40 for quick shut-off in large-diameter, low-pressure systems. It offers compact design and 90° operation for space-constrained installations. This valve suits water treatment or HVAC where full/unrestricted flow is needed.

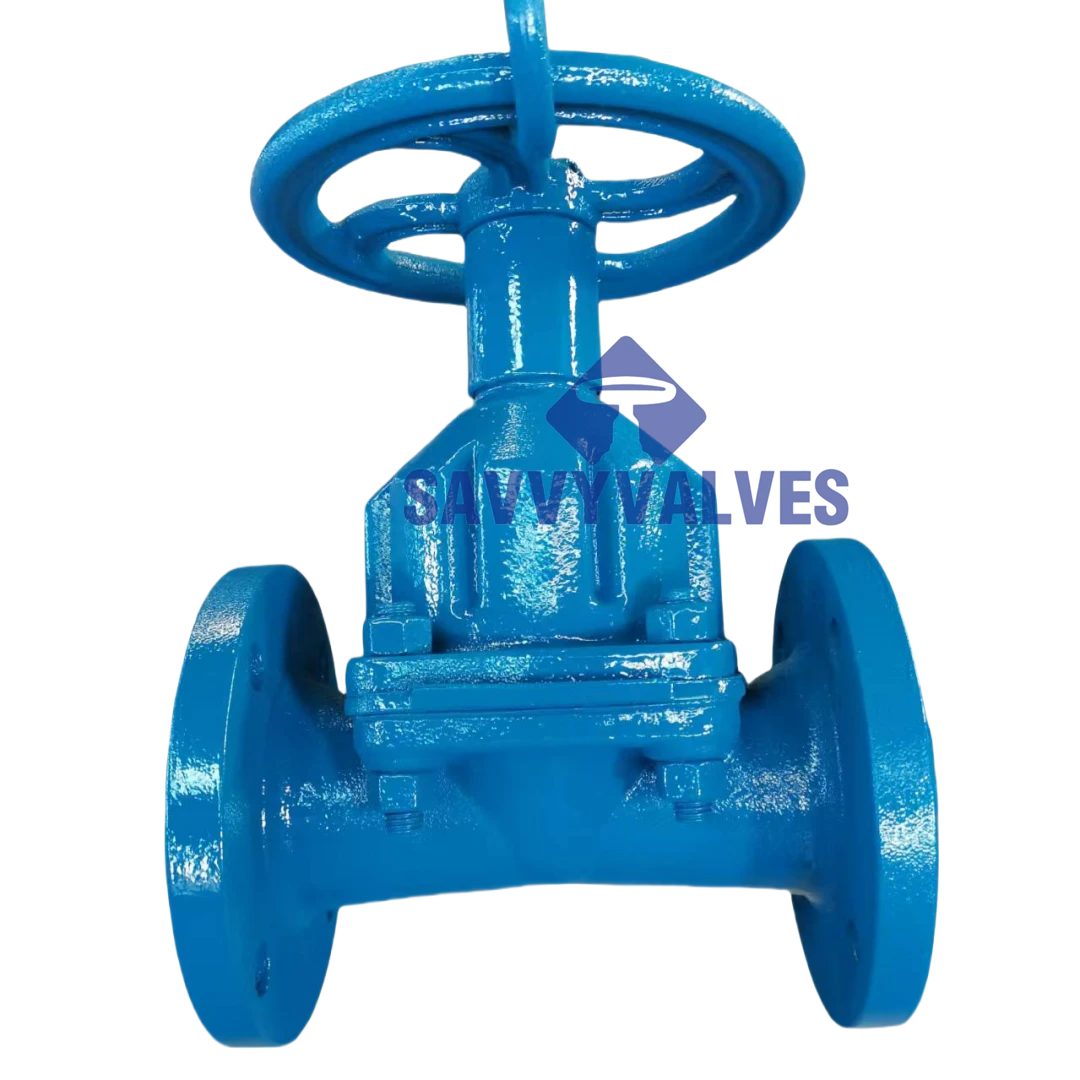

Q: How does Gate Valve DN40 handle high-pressure environments?

A: Gate Valve DN40 features a wedge mechanism that seals tightly against pipeline pressure. Its full-bore design eliminates flow restriction when fully open. This makes it optimal for isolation in oil/gas pipelines with minimal pressure drop.

Q: Between Globe Valve DN40 and Butterfly Valve DN40, which offers better flow control?

A: Globe Valve DN40 provides superior flow regulation with its linear motion stem and plug. Butterfly Valve DN40 has limited throttling precision due to its quarter-turn disc design. Choose Globe Valve for fine adjustments and Butterfly for on/off applications.

Q: Why would Gate Valve DN40 be preferred over Globe Valve DN40 for mainline isolation?

A: Gate Valve DN40 delivers zero flow resistance when fully open, minimizing energy loss. Its unidirectional sealing withstands higher pressures than Globe Valve DN40 in isolation scenarios. This makes it ideal for long-term shutoff in transmission pipelines.