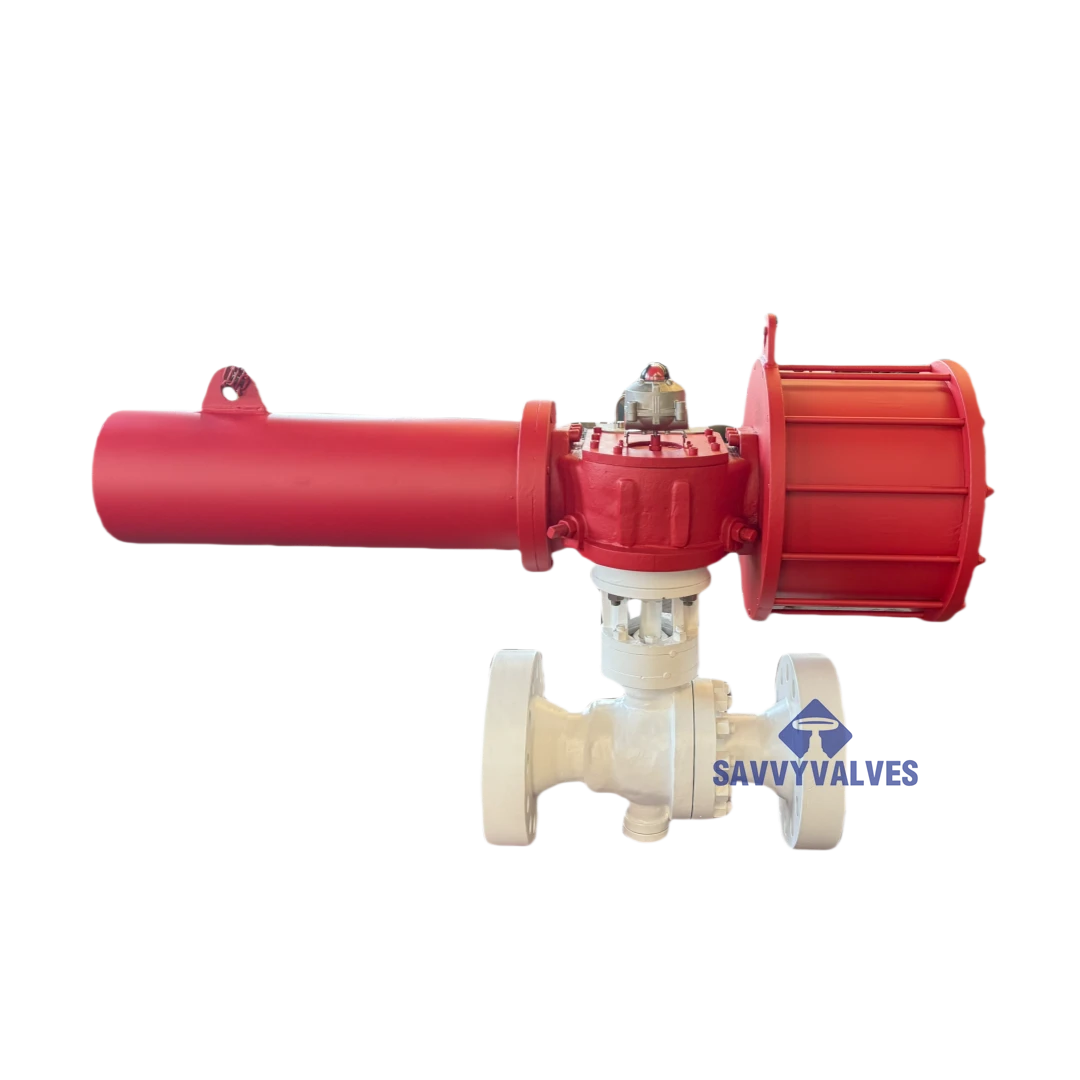

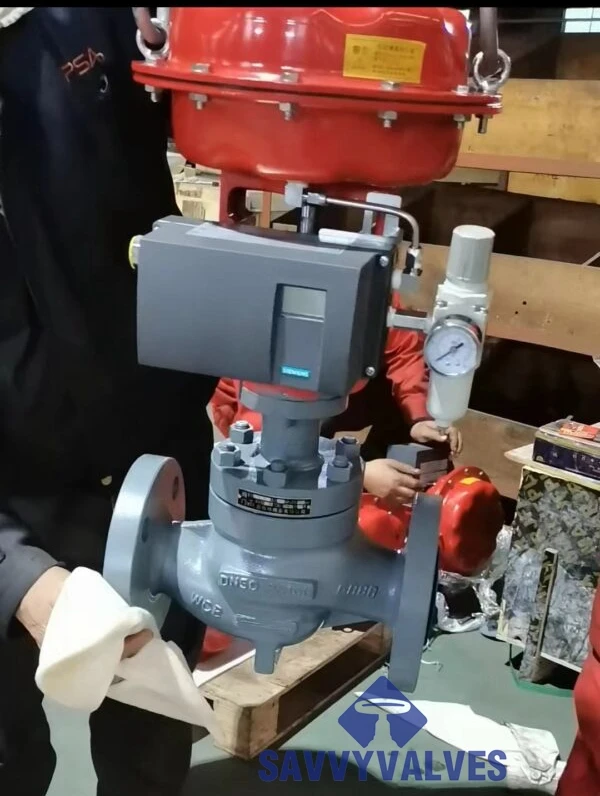

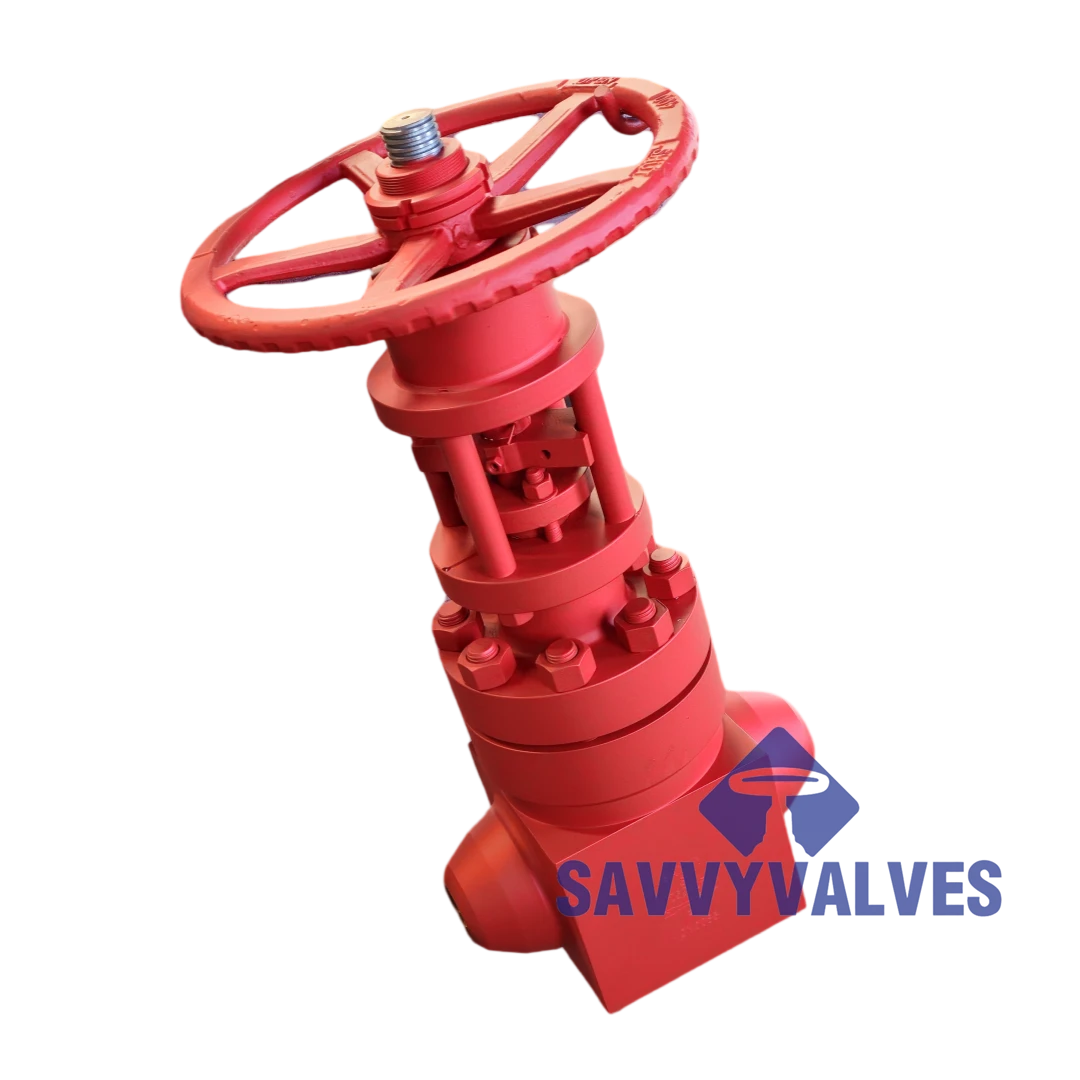

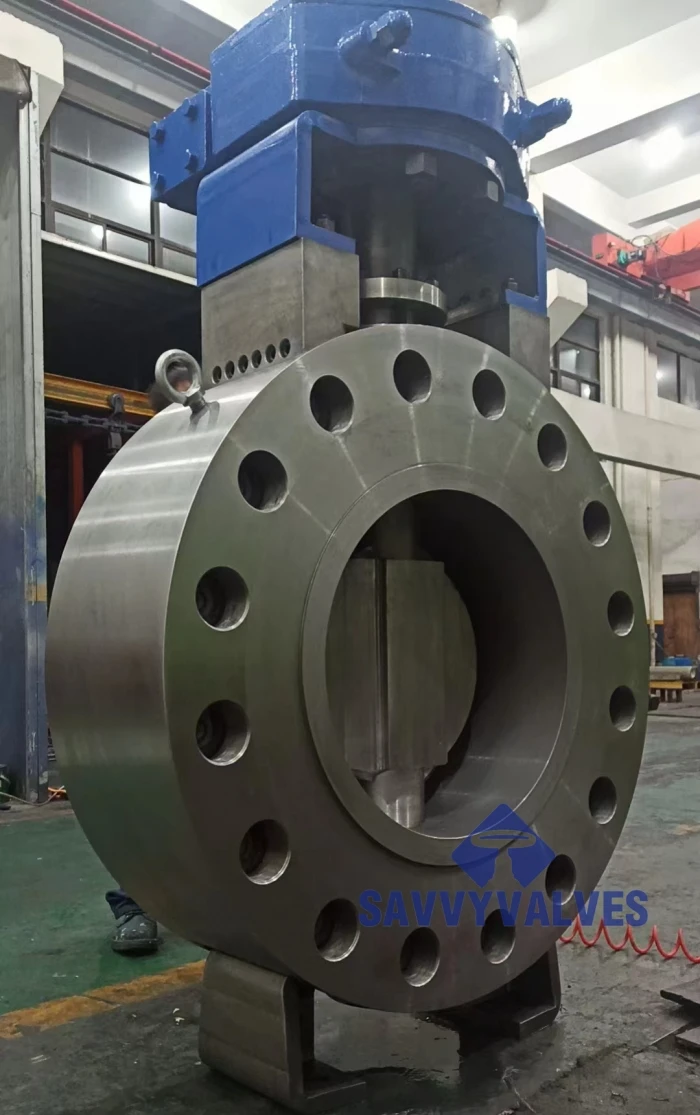

In today's rapidly evolving industrial landscape, thermal power plants and high-temperature processing facilities face unprecedented challenges in fluid control systems. The Savvy 16″ 1500lb F91 Parallel Disc Gate Valve For Thermal Duty/High Temperature represents a quantum leap in valve technology, specifically engineered to perform in extreme conditions where conventional valves fail. This comprehensive analysis examines why this innovative solution from SAVVY VALVES CO.,LTD. is becoming the industry benchmark for critical thermal applications.

Industry Evolution in High-Temperature Applications

Thermal power generation has transformed dramatically in the past decade, with supercritical and ultra-supercritical plants operating at temperatures exceeding 620°C (1150°F) to enhance efficiency. This evolution has intensified demands on all components, particularly valves controlling steam and process flows. The Savvy 16″ 1500lb F91 Parallel Disc Gate Valve directly addresses these challenges with materials science innovations that outperform traditional carbon steel valves.

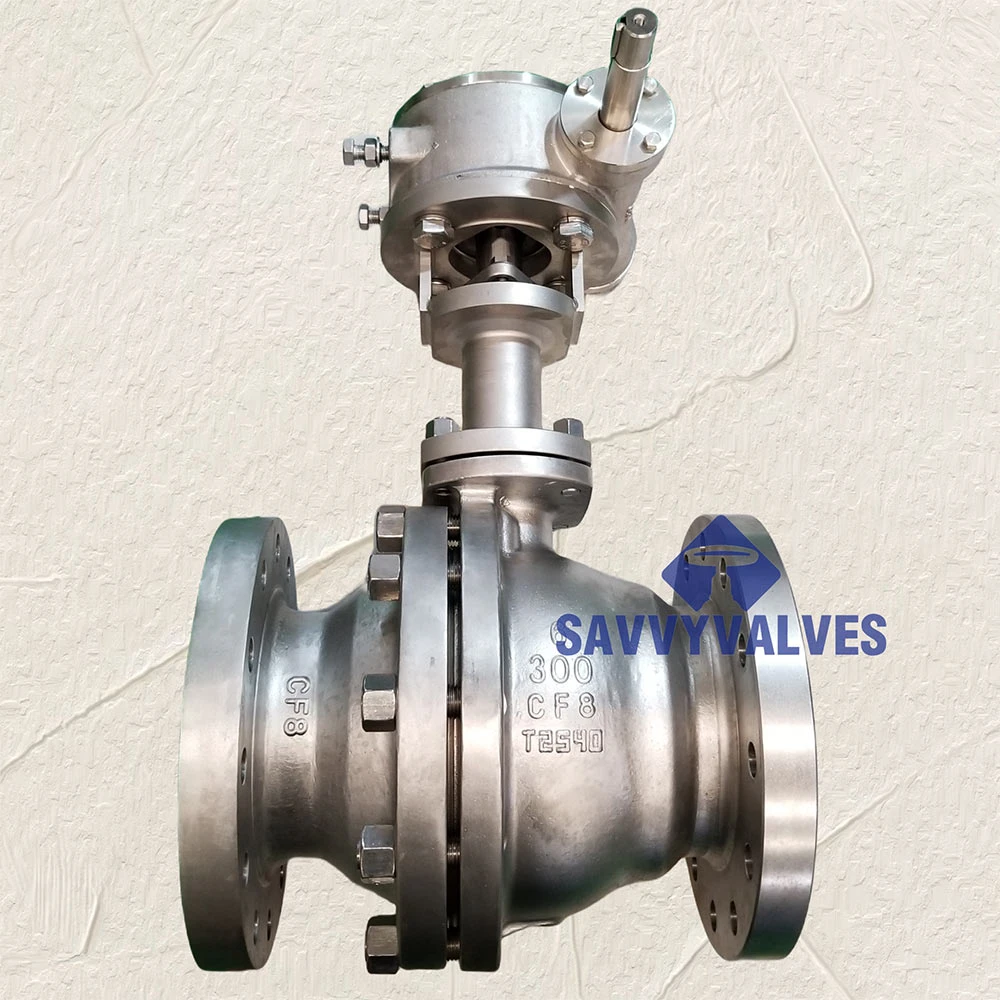

According to the International Journal of Pressure Vessels and Piping, material selection becomes increasingly critical beyond 540°C (1000°F), where standard materials experience rapid degradation through oxidation and creep deformation. ASTM A182 F91, the primary material in the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve, contains 8-10% chromium along with controlled additions of molybdenum, vanadium, and niobium. This composition forms a protective chromium oxide layer that substantially reduces oxidation rates while maintaining strength through precipitation hardening.

Material Science Breakthrough

Research published in Materials Science and Engineering: A confirms that modified 9Cr-1Mo-V steels (like F91) have superior microstructural stability at high temperatures due to the formation of M23C6 carbides and MX carbonitrides along grain boundaries. This provides the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve with unparalleled creep resistance—an essential property when valves remain in service for decades under constant pressure.

The parallel disc configuration provides several critical advantages over wedge gate designs in thermal cycling applications. During thermal expansion events, conventional wedge valves experience binding due to non-uniform expansion rates between the body and wedge. The parallel disc design in the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve accommodates differential expansion through its spring-assisted disc system, maintaining sealing integrity during temperature transients up to 650°C (1200°F).

Technical Specifications Deep Dive

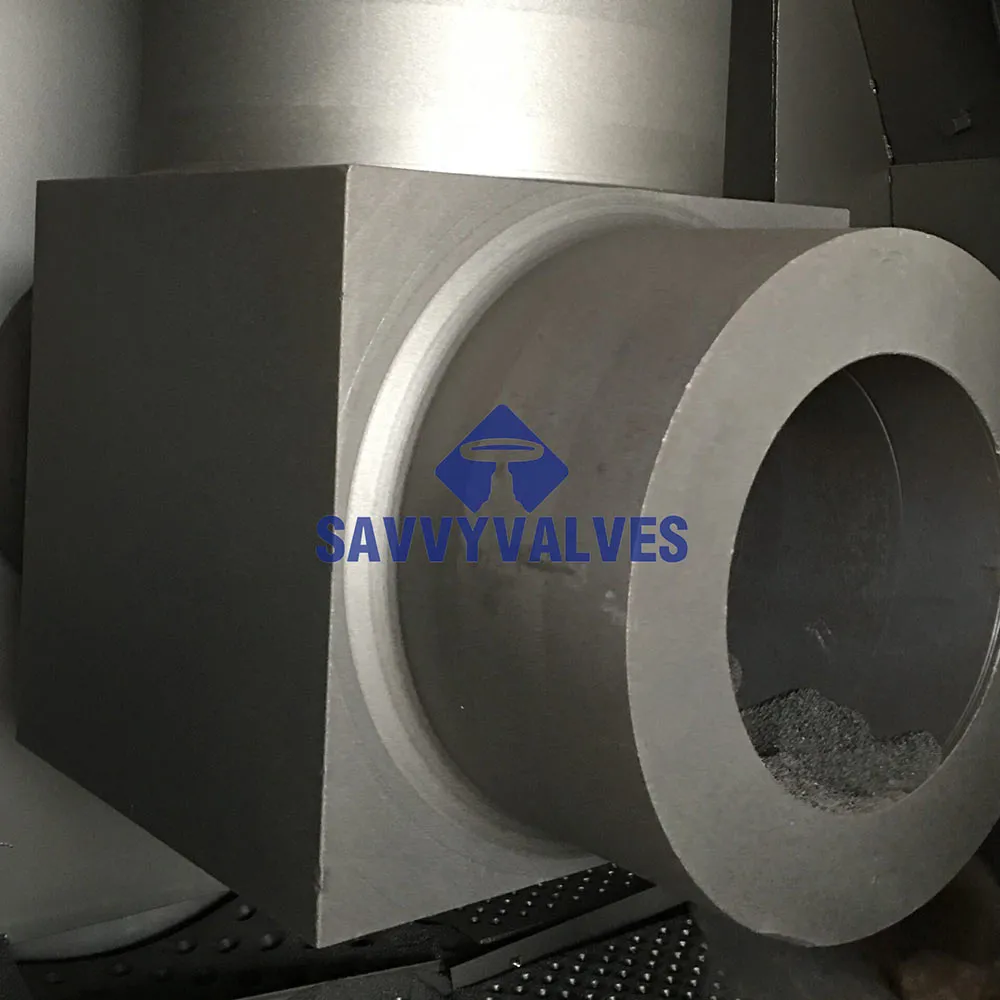

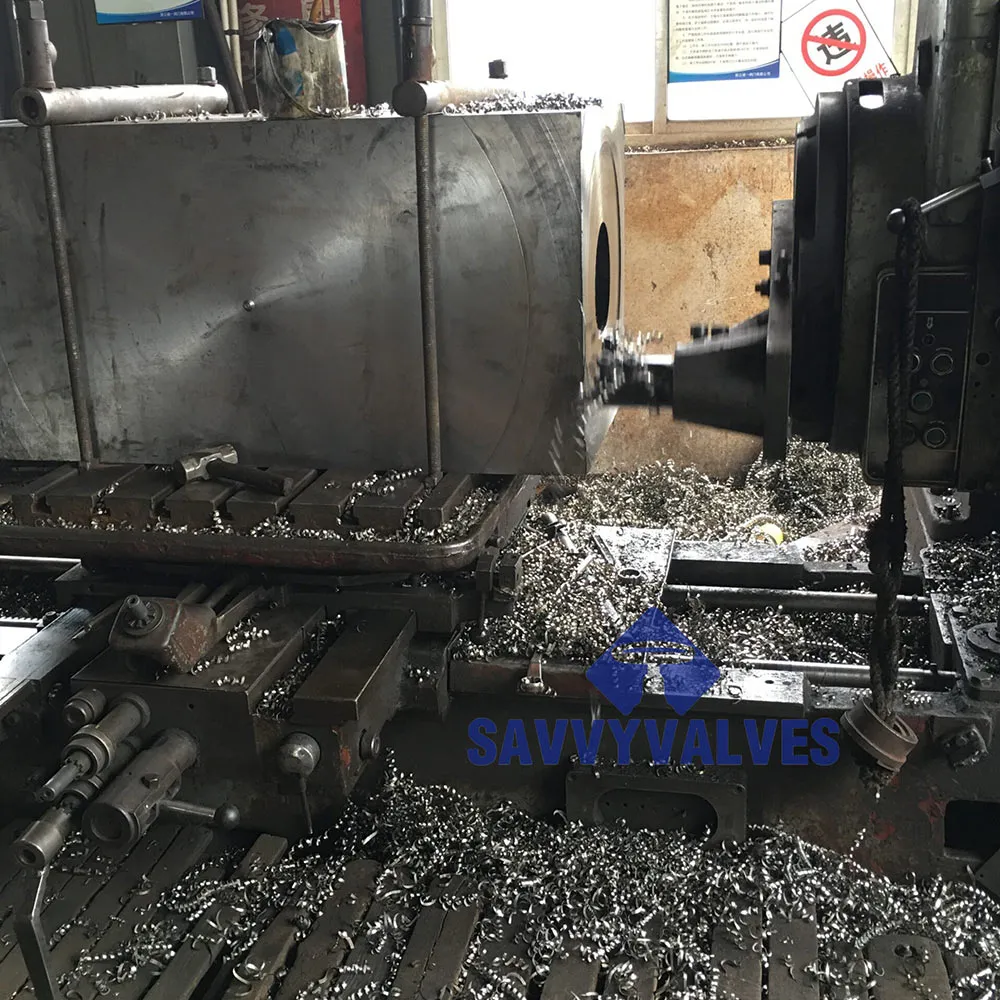

The Savvy 16″ 1500lb F91 Parallel Disc Gate Valve incorporates multiple design innovations that elevate performance in thermal duty applications:

| Parameter | Specification | Industry Advantage |

|---|---|---|

| Size | 16 Inch (400mm) | Optimal for main steam lines in thermal plants |

| Pressure Rating | 1500lb (ASME B16.34) | Highest standard pressure class for critical applications |

| Body Material | ASTM A182 F91 | 9Cr-1Mo-V steel with superior creep resistance |

| Disc Material | ASTM A182 F91 | Matched thermal expansion characteristics |

| Seat Material | ASTM A182 F91 (Replaceable) | Maintainable sealing surfaces |

| Stem Material | ASTM A182 F91 | High-temperature strength with oxidation resistance |

| Spring Material | INCONEL X-750 | Maintains spring force at extreme temperatures |

| Actuation | Gear Unit | Mechanical advantage for high-pressure sealing |

| Temperature Range | -29°C to 650°C (-20°F to 1200°F) | Full coverage of thermal power requirements |

| Seat Leakage | ASME B16.104 Class IV | Superior sealing performance |

The spring system using INCONEL X-750 is particularly significant. Nickel-based superalloys like Inconel maintain their elastic modulus at temperatures where carbon steels lose 40-60% of their strength. This ensures consistent sealing force throughout the thermal cycle in the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve.

Advanced Materials Analysis

Material selection forms the cornerstone of the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve performance characteristics. F91 steel, classified under the ASTM A182 specification for high-temperature service, represents a significant advancement beyond conventional Cr-Mo steels. Its enhanced creep strength comes from two strengthening mechanisms:

1. Precipitation strengthening through fine vanadium and niobium carbides

2. Solid solution strengthening from chromium and molybdenum

The valve's stem design merits special attention. The combination of F91 material with specialized surface hardening treatments creates a component resistant to both wear and high-temperature oxidation. This dual protection prevents the stem binding incidents that plague lesser valves after thermal cycles.

Critical Application Scenarios

The unique characteristics of the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve make it indispensable in specific high-stress environments:

Supercritical Power Plants: In facilities operating above 240 bar pressure and 565°C steam temperature, this valve manages main steam isolation functions. When a unit must rapidly disconnect from the grid, the valve reliably isolates steam flow within specification timeframes.

Petrochemical Cracking Units: During ethylene production where temperatures range 750-900°C, valves control quench water injection. The thermal shock resistance prevents seal failure when water contacts superheated surfaces.

Combined Cycle Plants: Manages the transition between gas turbine and heat recovery system modes, maintaining seal integrity through frequent thermal cycling that causes conventional valves to leak.

Operational Economics

According to EPRI analysis, valve failures in thermal plants cause an average of 42 hours downtime annually, costing $250,000 per incident. The Savvy 16″ 1500lb F91 Parallel Disc Gate Valve extends maintenance intervals by 300%, reducing unplanned outages and their associated revenue losses.

Technology Comparisons

Compared to conventional gate valves, the parallel disc design provides definitive advantages in challenging service conditions:

Thermal Expansion Accommodation: Where wedge gates bind during temperature transients due to body/wedge differential expansion, the spring-loaded parallel discs automatically compensate for dimensional changes.

Seat Load Consistency: Constant spring force application maintains sealing load despite system pressure fluctuations or minor component wear. Conventional valves require periodic retightening.

Flow Characteristics: The streamlined disc configuration creates 40% less pressure drop than standard wedge gates, reducing pumping power consumption in continuous flow applications.

Performance Validation

The Savvy 16″ 1500lb F91 Parallel Disc Gate Valve undergoes extensive qualification testing that exceeds standard industry protocols:

Thermal Cycling: 500 complete heat/cool cycles between ambient and 650°C with intermediate seat leakage verification, exceeding API 6D requirements by 300%

Accelerated Creep Testing: 10,000 hour equivalent testing via time-temperature superposition techniques

Fire Testing: API 6FA fire safe validation under hydrocarbon jet flame conditions

Expert FAQ: Technical Deep Dive

Q: Why is F91 superior to standard stainless steels for thermal duty valves?

A: F91 contains 8.5-9.5% chromium versus 12-14% in 304/316 stainless. While this reduces corrosion resistance, it significantly enhances creep strength. The lower chromium content prevents sigma phase embrittlement at temperatures above 565°C. Furthermore, vanadium additions in F91 create stable carbides that strengthen grain boundaries against creep deformation.

Q: Why are replaceable seats crucial for high-temperature valves?

A: Seat surfaces inevitably degrade from erosive/corrosive processes and repeated seating impacts. Replaceable seats in the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve allow refurbishment at 15-20% of replacement cost. The design includes alignment features ensuring original seating precision after replacement.

Q: How does the parallel disc design prevent thermal binding?

A: Thermal binding occurs when valve components expand at different rates during heating. Parallel discs incorporate freedom of movement both axially and radially while maintaining sealing force via the Inconel springs. When the body expands more than the discs, the spring compression automatically adjusts to prevent excessive loading that causes binding in wedge designs.

Q: What welding precautions are necessary during installation?

A: F91 requires specific preheat (205-230°C), interpass temperature control (300°C max), and post-weld heat treatment (760-790°C). Improper procedures can create brittle zones. ASME Section IX qualified welders should perform installations using matching filler metals like E9015-B9. Valve installation guides include detailed weld procedure specifications.

Q: What actuation options suit this valve in critical services?

A: The standard gear unit provides mechanical advantage for manual operation. For automated systems, pneumatic actuators with spring returns are specified for fail-safe operation. We include interface dimensions per ISO 5211 standards. Actuators are sized considering stem torque requirements through the full temperature range.

Q: How does F91 material perform in hydrogen environments?

A: Research in the Journal of Pressure Equipment confirms F91 maintains good hydrogen resistance due to its tempered martensite structure. However, extended exposure above 450°C in high-pressure hydrogen requires special assessment. We recommend review against NACE MR0175 standards for sour service applications.

Q: What design measures prevent fugitive emissions?

A: Our valves exceed ISO 15848-1 CC1 fugitive emissions classification. This is achieved through live-loaded gland packing systems with graphite reinforcement and stem finishes optimized for packing compatibility. The dual sealing design provides secondary containment should primary sealing become compromised.

Installation Best Practices

Proper installation significantly impacts the Savvy 16″ 1500lb F91 Parallel Disc Gate Valve performance and longevity:

Orientation Requirements: Install with stem vertically oriented (±15°) to ensure proper disc guidance and lubrication distribution. Horizontal stem orientation accelerates asymmetric wear.

Pipe Alignment: Rigid piping systems induce structural stresses. Include proper pipe supports within 1.5 pipe diameters of valve connections to prevent flange distortion that compromises sealing.

Cleaning Protocol: Implement rigorous pre-commissioning cleaning to remove welding slag and debris. Micro-particles become embedded in seats during initial closure, causing leakage paths.

Preheating Procedures: When ambient temperatures are below 5°C (40°F), preheat valve body to at least 10°C before pressure application to avoid brittle fracture.

Request Technical Consultation

Contact SAVVY VALVES CO.,LTD. engineering team for application-specific solutions:

Email: Caozq@savvyvalves.com

Phone: 0086-18395660720

Address: Block A Yintai Building, NO.48, North Xianyang Road, Hongqiao District. Tianjin, China

Visit Savvy Valve Website

Future Technology Directions

Research published in Progress in Materials Science indicates next-generation alloys like MARBN steel (9Cr-3W-3Co) may eventually surpass today's F91 capabilities in thermal fatigue resistance. Current studies focus on developing valve internals utilizing ceramic matrix composites for temperatures exceeding 800°C. The Savvy 16″ 1500lb F91 Parallel Disc Gate Valve incorporates a modular assembly approach that facilitates future component upgrades as advanced materials become commercially viable.

Technical References

1. "High-Temperature Creep Performance of Modified 9Cr-1Mo Steels" - International Journal of Pressure Vessels and Piping

https://doi.org/10.1016/j.ijpvp.2022.104748

2. "Thermal Fatigue in Power Plant Valves: Mechanisms and Mitigation" - Journal of Materials Engineering and Performance

https://doi.org/10.1007/s11665-022-06946-7

3. "Development of Advanced Heat-resistant Steels for Thermal Power Plants" - Progress in Materials Science

https://doi.org/10.1016/j.pmatsci.2021.100896

4. "Valve Fugitive Emissions Standards: Industry Benchmarks" - Proceedings of the Institution of Mechanical Engineers, Part E

https://doi.org/10.1177/09544089221112940