316 Stainless Steel Full Lug Knife Gate Valve represents a critical solution in fluid isolation for sectors like petrochemical, mining, pulp & paper, water treatment, and more. As worldwide investments in industrial infrastructure expand and stricter process reliability and corrosion resistance standards emerge, the demand for advanced knife gate valves—especially those constructed from 316 stainless steel—shows robust growth.

- According to MarketsandMarkets, the global industrial valves market is projected to reach USD 90.5 billion by 2027, with stainless steel valves claiming rising shares due to superior life cycle value.

- Recent surveys (Grand View Research 2023) highlight a CAGR of 5.8% for stainless steel valves globally, driven by modernization and tough service demands.

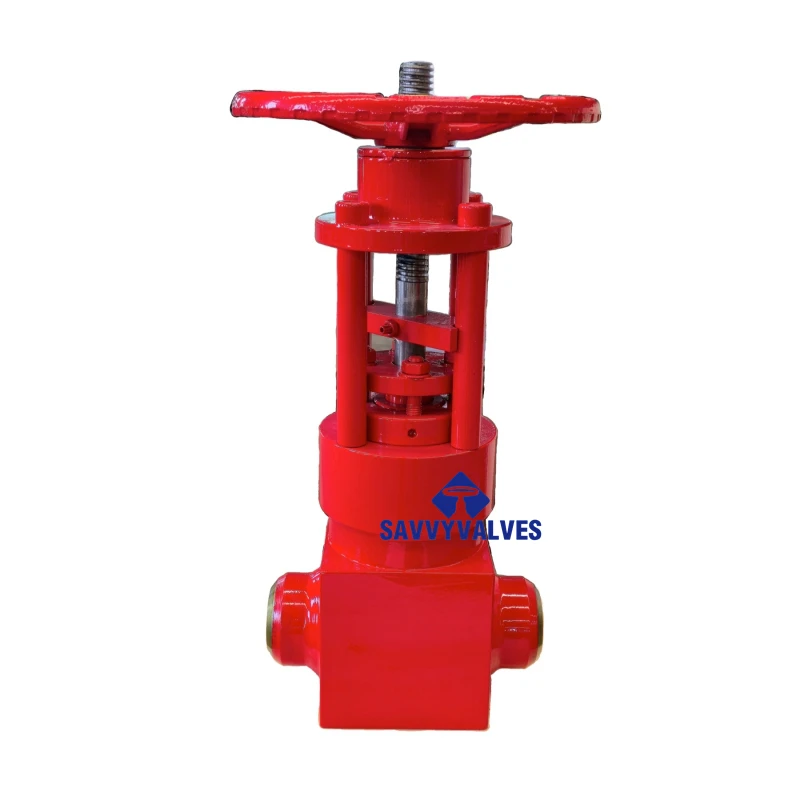

Prototyping stage of the 316 Stainless Steel Full Lug Knife Gate Valve

| Technical Parameter | Specification | Testing Standard | Typical Value |

|---|---|---|---|

| Valve Body Material | 316 Stainless Steel (ASTM A351 CF8M) | ASTM, EN 10204 | 18% Cr, 10% Ni, 2% Mo |

| Gate Material | 316/316L Stainless Steel | EN 10088 | 2B Finish, 180–240 grit |

| Connection Type | Full Lug (ASME B16.5) | ANSI, EN1092 | DN50 – DN1200, PN10/16, Class 150 |

| Design Pressure | Up to 16 bar (232 psi) | ANSI/API 598 | 10/16 bar/20°C |

| Operating Temp. | -29°C ~ 230°C (-20°F ~ 446°F) | ISO 5208 | Nominal – 180°C |

| Face-to-Face | EN 558-1, MSS SP-81 | ISO 5752 | Standard/Customized |

| Seat Type | Integral Metal / EPDM / PTFE | ISO 5208 | Metal (default) |

| Testing | Hydrostatic & Air Test | API 598, ISO 5208 | 100% Passed |

| Certifications | CE, ISO 9001:2015, WRAS | European Directive | Available |

- Raw Material Selection → ASTM A351 CF8M certified 316 stainless steel billets.

- Casting/Forging → Shell & gate components cast/forged under strict metallurgical controls. (ISO 9001, EN10204 certified)

- CNC Machining → All wetted surfaces, seats, and gate guides are precision-machined using 5-axis CNC to ±0.02mm tolerance.

- Welding & Assembly → Automated TIG welding, full lug integration, and anti-corrosion surface treatments.

- Surface Finishing → Pickling, passivation, and 2B finishing meet EN 10088 standard.

- Testing & QA → Hydrostatic and air test (API 598, ISO 5208 certified), PMI (Positive Material Identification), and full traceability records.

- Packing & Logistics → Export packaging with certificate, ready for global shipment.

This comprehensive process assures durability, excellent dimensional precision, and strict compliance with ISO 9001:2015, API 598, and CE directives. Additionally, each 316 Stainless Steel Full Lug Knife Gate Valve undergoes third-party inspection, enhancing process traceability and lifecycle integrity.

- Supreme Corrosion Resistance: 316 stainless steel offers outstanding resistance to chloride-induced pitting, crevice corrosion & acidic/alkaline fluid media (per ASTM G48, NACE MR0175 recommendations).

- Full Lug Design: Enables end-of-line service, providing reliable tight shutoff—even if the downstream line is removed.

- High Working Pressure & Temperature: Up to 16 bar and 230°C, outperforming 304 series or iron-valved units, validated by API 598 tests.

- Maintenance Friendly: Replaceable seat and stuffing box design; option for PTFE, metal, or elastomer seats.

- Longevity: Typical cycle life exceeds 80,000 open/close operations with routine maintenance.

- Global Certifications: CE, PED, ISO 9001, WRAS, and conformance to ANSI, DIN, JIS flanging standards.

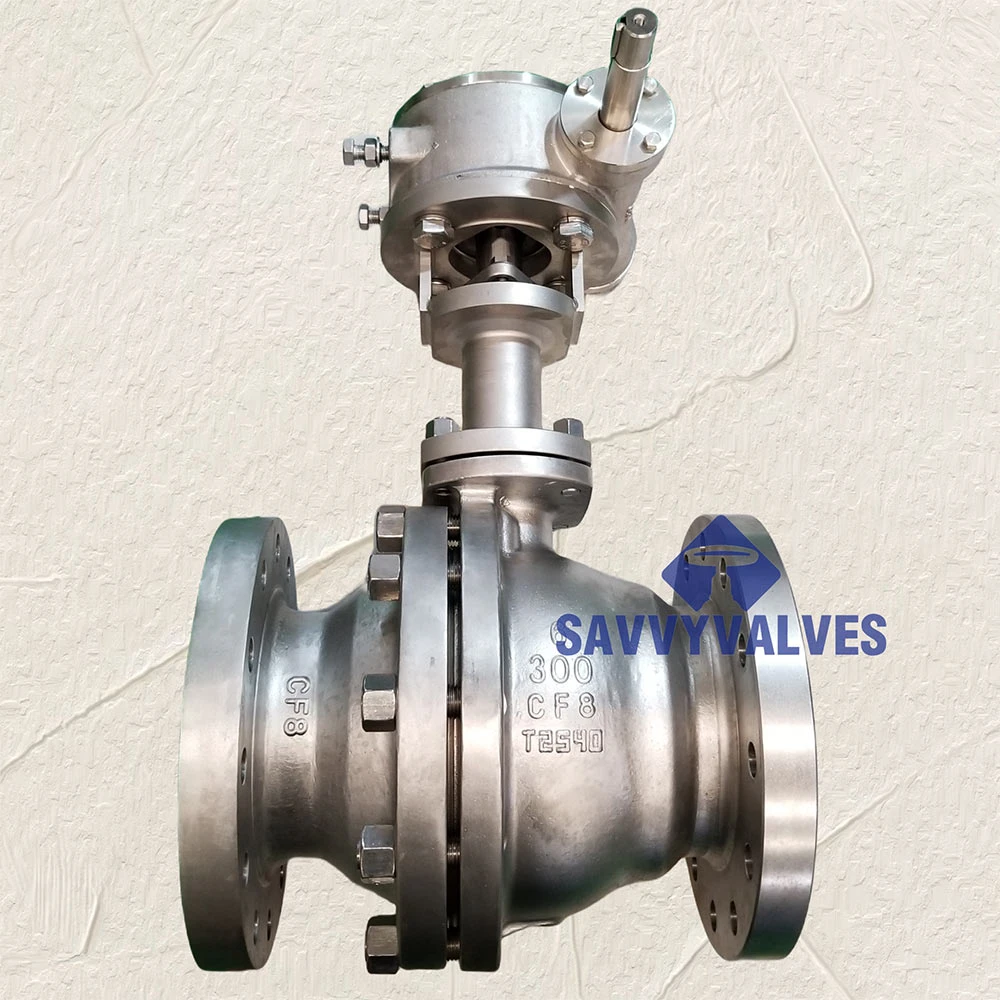

Anti-corrosion test scenario using 316 Stainless Steel Full Lug Knife Gate Valve

| Maker | Country | Material Source | Certifications | Custom Engineering | Lead Time | Warranty |

|---|---|---|---|---|---|---|

| Savvy Valve Tech | China | POSCO, Baosteel | CE, ISO, WRAS | Yes, in-house CNC | 18–25 days | 24 months |

| Orbinox | Spain | Acerinox | CE, ISO | Yes | 30–45 days | 24 months |

| Velan | Canada | Outokumpu | CE, PED, API | Partial | 35–55 days | 18 months |

| DeZURIK | USA | AK Steel | NSF, ISO | Yes (premium) | 28–40 days | 24 months |

As data shows, Savvy Valve Tech offers a unique blend of rapid delivery, global certification, and in-house customization capabilities for 316 Stainless Steel Full Lug Knife Gate Valve solutions.

- Valve Size: DN50–DN1200, with special modifications on request.

- Actuation Solutions: Manual, pneumatic, electric, or hydraulic actuators.

- Seat Material Choices: Metal (default), PTFE, EPDM, Viton based on media compatibility (per GF Piping Systems recommendations).

- Flange Standards: ASME B16.5/EN1092/JIS - fully interchangeable

- Coating & Surface Treatment: Special passivation, electropolishing for food/pharma.

- Document Traceability: 3.1/3.2 MTCs (EN 10204 standard), full NDT report, and pressure testing charts.

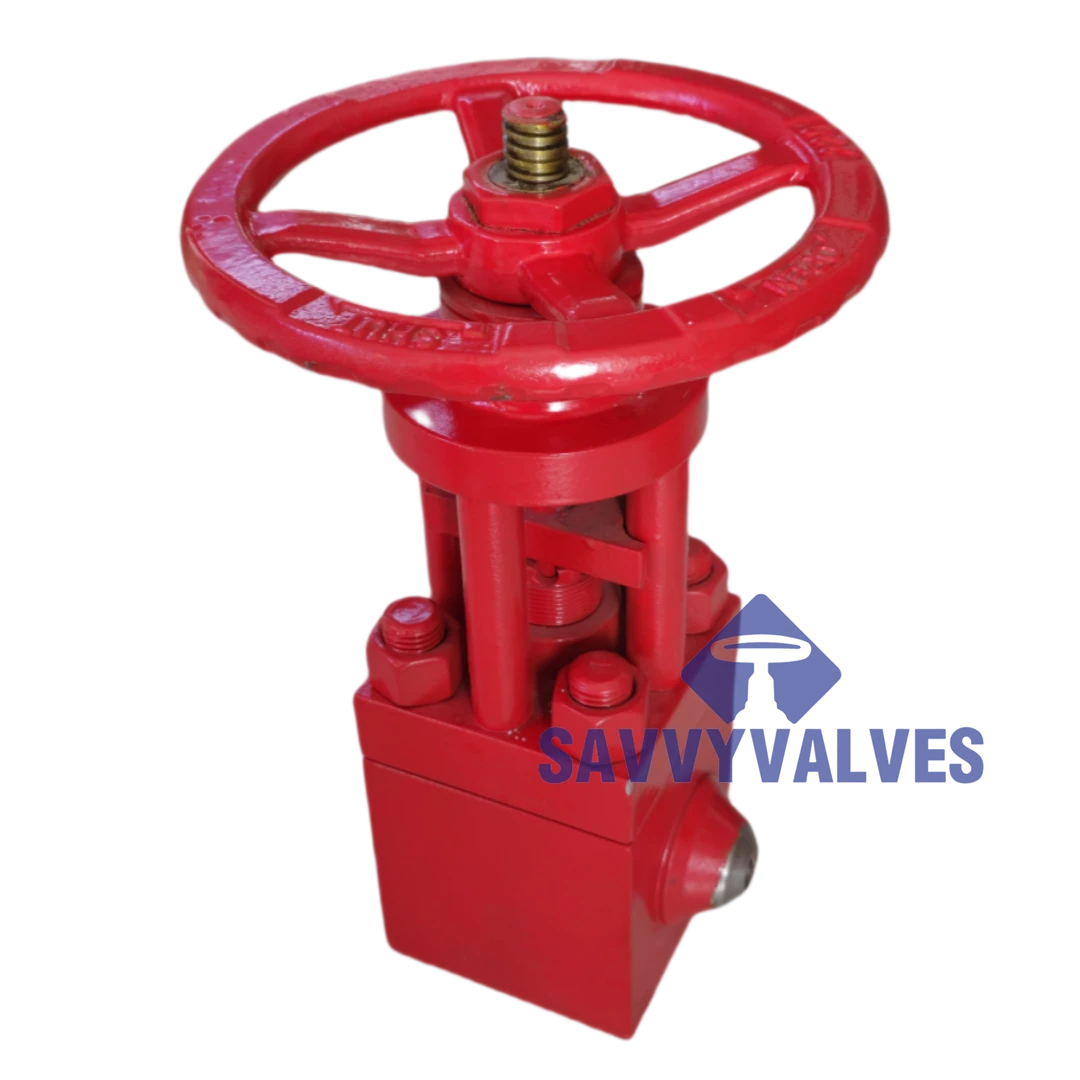

Customizations for various industries using 316 Stainless Steel Full Lug Knife Gate Valve

Bespoke solutions enable clients to meet strict plant design, low total cost of ownership, and regulatory requirements. Engineering support includes 3D modeling, fluid simulation, and CFD validation.

Mining Slurry System: One of Australia's largest gold mines deployed 68 units in high-turbidity slurry pipelines, reporting 75,000+ cycles without unscheduled repair—demonstrating the valve's superior abrasion and pitting protection.

Municipal Wastewater: European water utility integrated full-lug design for both end-of-line service and line isolation; 100% leak tightness confirmed by third-party ISO 5208 tests.

Pulp & Paper: A Scandinavian paper mill handled heavily fiber-laden process streams using the knife gate, benefiting from easy seat replacement and reduced stock loss.

- Production Lead Time: 18–25 calendar days (custom valves may add 8–12 days).

- Warranty: 24 months from shipment, covering all manufacturing and material defects.

- Support: Global technical support via email/video, 24/7 response for emergencies.

- Testing Report: 100% API 598 & ISO 5208 hydrostatic & air seat test record with each shipment.

- After-Sales: Free consulting, spare parts, fast troubleshooting (within 48 hours for critical sites).

The 316 Stainless Steel Full Lug Knife Gate Valve emerges as a premier choice where ultimate corrosion resistance, positive shutoff, and extended service life are mission critical. Backed by multi-industry field data, leading-edge manufacturing, and total service coverage from reputable suppliers, these valves set a new performance standard across the industrial sector. For bespoke engineering, lifecycle partnership, or technical consultation, Savvy Valve Tech delivers with excellence and reliability.

[1] Valve World – Stainless Steel Knife Gate Valves in Harsh Applications

[2] Grand View Research – Global Valve Market Report 2023

[3] Chemical Engineering Journal, 2022: “Knife Gate Valve Performance in Chloride Brine Service”

[4] Chemical Engineering Magazine

[5] Pumps & Systems: Knife Gate Valve Material Selection

[6] Industrial Valve Research Forum