- Factors affecting butterfly valve pricing and industry cost drivers

- Comparative pricing analysis across different valve sizes

- Technical specifications influencing cost and performance

- Leading manufacturers comparison with data tables

- Budget optimization through customized valve solutions

- Case studies demonstrating real-world applications

- Strategies for achieving cost-effective procurement

(3 inch butterfly valve price)

Key Factors Affecting 3 Inch Butterfly Valve Price

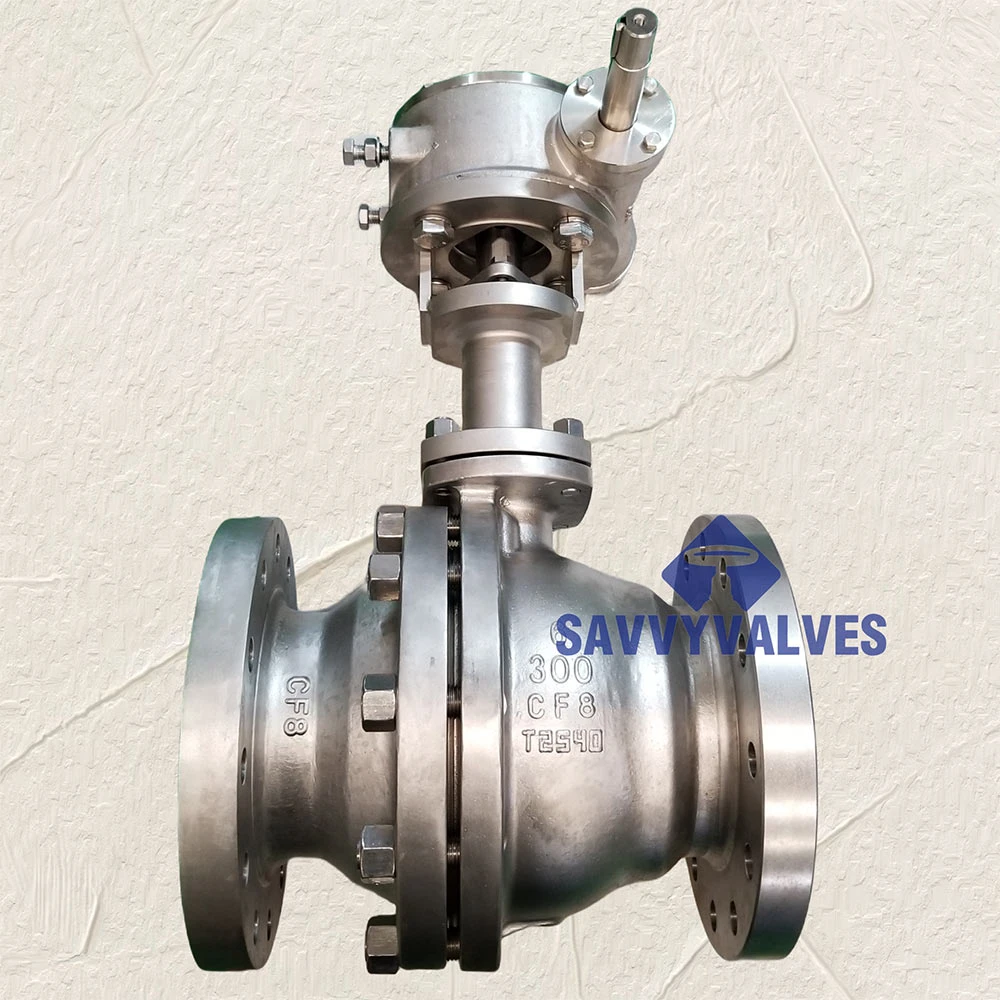

Material composition remains the primary cost driver in butterfly valve manufacturing. Industrial-grade stainless steel models (CF8M) typically command 40-60% higher butterfly valve 2 inch price points than cast iron alternatives due to superior corrosion resistance and longevity. Operational pressure ratings create significant price stratification - valves rated for 250 PSI start at $250 for a 3" model, while 600 PSI-rated versions begin at $650 for the same 3 inch butterfly valve price

range.

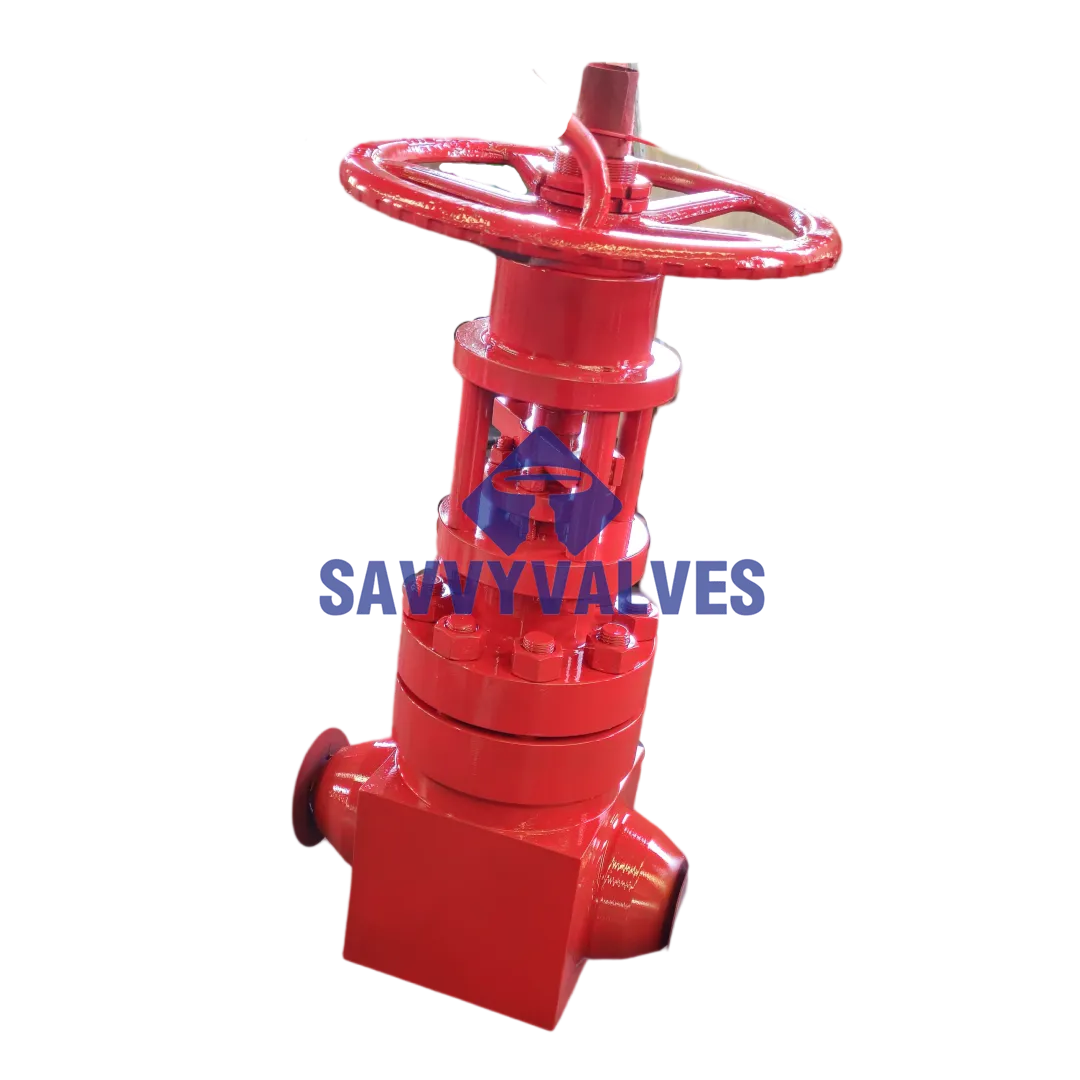

Operational mechanisms dramatically impact cost structures. Manual 3 inch butterfly valve installations average between $280-$420 depending on gearbox quality, while actuated systems with pneumatic controls start at $550 and can exceed $2,500 with smart controls integration. Sealing technology introduces substantial variations - EPDM seats add 15% to base pricing whereas PTFE and triple-offset metal solutions increase costs by 45-80%. Third-party certifications like API 609 and ISO 5211 compliance typically add 20-35% to baseline pricing across all valve sizes.

End-to-end maintenance requirements influence life-cycle expenses significantly. Quarterly maintenance of standard valves averages $180 per service visit, whereas certified zero-leakage designs reduce this to $75 quarterly - yielding approximately 58% lower operational costs over a ten-year period. Properly maintained premium valves demonstrate mean-time-between-failures (MTBF) of 10-15 years versus 5-7 years for economy units.

Comparative Pricing Across Valve Sizes

Price scaling follows non-linear patterns across valve diameters. The butterfly valve 2 inch price typically ranges between $130-$280 for commercial-grade units, while upgrading to a 3 inch model increases investment to $240-$540 - representing approximately 85% price escalation for a modest size increase. However, industrial-scale applications reveal inverse economies: while the butterfly valve 12 inch price averages $3,200-$6,800 per unit, this constitutes just $265-$567 per inch - 62% lower than the per-inch cost of smaller valves.

Installation complexity compounds price differences significantly. The butterfly valve 4 inch price typically includes $120-$380 in ancillary components (flanges, gaskets, fasteners) whereas 12-inch industrial installations require $980-$2,100 in supplementary hardware. Labor costs exhibit disproportionate growth - skilled technician installation ranges from 1.5 hours ($210) for 2-inch valves to 8 hours ($1,120) for 12-inch units. Consider pipeline retrofit projects where replacing smaller valves increases project costs by 35% versus 18% for similar replacements in larger diameters.

Bulk purchasing discounts create notable deviations from standard pricing. Orders exceeding fifty 3-inch units trigger 12-18% discount structures, while large industrial contracts for butterfly valve 12 inch price procurement typically secure 22-30% reductions. However, transportation logistics reverse some savings - shipping costs per pound range from $1.25 for 2-inch valves to just $0.38 for 12-inch versions, yet absolute shipping cost increases from $16 to $240 across this size spectrum.

Technical Specifications and Performance Metrics

Flow coefficient (Cv) measurements quantify performance efficiency differences. While a standard 3-inch valve achieves Cv=110, precision-engineered alternatives reach Cv=190 - delivering 42% higher flow capacity without altering pipe dimensions. High-performance valves demonstrate consistent torque requirements below 140 lb-ft at 80 PSI, reducing actuator costs by 25-40% compared to standard alternatives.

Material durability metrics reveal significant longevity variations. Carbon steel valves withstand 6-12 years of continuous service before seal degradation, whereas duplex stainless steel versions consistently exceed 20-year service life in identical environments. Testing data shows premium valves maintain bubble-tight sealing integrity through 50,000 actuation cycles (per API 598 requirements) versus 15,000 cycles for basic alternatives.

Temperature tolerances create specialized application pricing tiers. Standard EPDM-seated valves operate reliably up to 250°F, but PTFE-composite solutions extend this range to 400°F at 30-50% higher costs. For cryogenic applications (-320°F), specialized extended-stem designs with thermal barriers command 75-90% price premiums over conventional valve configurations.

Leading Manufacturer Comparison

| Manufacturer | 3" Price Range | 4" Price Range | 12" Price Range | Warranty | Pressure Rating | Material Options |

|---|---|---|---|---|---|---|

| ValvTechnologies | $520-$780 | $610-$950 | $4,200-$6,200 | 10 years | ANSI 900 | SS316, Alloy 20 |

| Emerson | $380-$670 | $470-$820 | $3,800-$5,600 | 7 years | ANSI 600 | Carbon Steel, SS304 |

| Flowserve | $350-$590 | $430-$740 | $3,500-$5,100 | 5 years | ANSI 300 | Cast Iron, Ductile Iron |

| Bray International | $310-$540 | $390-$680 | $3,100-$4,500 | 5 years | ANSI 150 | Bronze, SS316 |

Warranty coverage differences reflect manufacturer confidence levels. Premium suppliers typically offer 20,000-hour operational warranties without maintenance requirements versus standard 8,000-hour coverage. Field failure statistics reveal brand performance variations - top-tier manufacturers report 1.2-1.8% failure rates during the first five years, compared to 3.5-4.8% for economy producers.

Third-party certifications distinguish quality benchmarks. Manufacturers with ISO 15848-1 fugitive emissions certification typically charge 15-25% higher prices, yet demonstrate methane emissions below 50 ppm versus 500+ ppm for non-certified alternatives. API 607 fire-tested valves command 30-45% premiums while reducing fire-containment failure risks by 78% according to industrial safety audits.

Customized Valve Solutions

Specialized trimming optimizes operational expenses significantly. Requesting reduced-port 3-inch designs decreases material costs by 20-25% while maintaining flow capacity for specific applications. Extended backseat configurations add 15-20% to the base butterfly valve 2 inch price but decrease maintenance frequency by 60% in inaccessible installations.

Alternative material specification creates balanced performance-cost solutions. Specifying CF3M stainless steel instead of CF8M offers 20% cost reduction with equivalent chemical resistance for temperatures below 400°F. Industry data indicates composite seal integration reduces part-replacement costs by 35-50% compared to traditional rubber alternatives while achieving identical sealing performance.

Production modifications carry predictable cost implications. Fire-safe certification adds 12-18% to manufacturing expenses while providing critical safety compliance. Nuclear-quality validation procedures contribute 30-45% to production costs, though they remain essential for specialized applications. Custom face-to-face dimensions involve 8-15% design surcharges but can eliminate 90% of installation adaptation expenses.

Industry Implementation Case Studies

Municipal water treatment facilities demonstrate dramatic lifecycle savings. The City of Austin reported $240,000 operational savings over eight years following standardization on premium-quality 12-inch valves despite higher initial butterfly valve 12 inch price investments. Maintenance frequency decreased from quarterly to biennial servicing, reducing labor expenditures by 68% annually while achieving zero process downtime.

Chemical processing plants reveal precision specification benefits. BASF's Geismar facility documented 27% lower total procurement costs through optimized material selection - implementing nickel-aluminum-bronze valves in moderately corrosive applications instead of high-nickel alloys. The strategy balanced initial investment against operational longevity, achieving 3.2-year ROI without compromising safety standards.

Energy generation facilities confirm reliability-cost relationships. Duke Energy's combined-cycle plants extended scheduled maintenance intervals from 18 to 36 months after installing triple-offset valves with metal sealing surfaces. Though carrying 55% higher initial purchase costs than standard designs, the enhanced valves reduced forced outages by 85% and lowered maintenance expenses by approximately $1.2 million annually per facility.

Strategies for Optimizing Butterfly Valve 2 Inch Price and 4 Inch Price

Procurement timing significantly influences project costs. Market analysis indicates quarterly price fluctuations up to 9% in the 2-4 inch valve segment based on raw material indices. Historical data shows Q2 purchases yield 3-5% savings compared to Q4 when industrial projects peak. Establish framework agreements locking in current butterfly valve 4 inch price structures for future projects through volume commitments.

Technical specification refinement generates substantial savings. By adjusting pressure class requirements from ASME 300 to ASME 150 where process conditions permit, facilities typically save 22-28% on valve acquisition costs. Selective upgrading of critical-path valves versus economy units for non-critical applications generates 15-25% overall budget reduction without compromising system integrity.

Lifecycle cost analysis supersedes initial purchase focus. Premium 4-inch valves with extended warranties demonstrate 40-60% lower maintenance and replacement expenses over 15-year operational periods. Operators utilizing predictive maintenance technologies report 18% longer service life through optimized servicing scheduling, effectively reducing per-year operational costs by 27% despite higher initial butterfly valve 4 inch price investments.

(3 inch butterfly valve price)

FAQS on 3 inch butterfly valve price

Q: What factors affect the 3 inch butterfly valve price?

A: The price depends on materials (e.g., cast iron vs stainless steel), pressure rating, and brand. Additional features like gear operators or certifications can increase costs. Request quotes with specs for accurate pricing.

Q: How does butterfly valve 12 inch price compare to smaller sizes?

A: A 12-inch butterfly valve typically costs 3-5x more than a 3-inch valve due to heavier materials and complex manufacturing. Larger flanges and actuators also contribute to higher prices. Always compare specifications beyond size alone.

Q: Why is butterfly valve 2 inch price lower than larger models?

A: Reduced material requirements and simplified production make 2-inch valves more economical. Their compact size also lowers shipping/handling expenses. However, specialized alloys may narrow this price gap.

Q: Where can I get accurate butterfly valve 4 inch price quotes?

A: Contact manufacturers directly or use industrial marketplaces like ThomasNet. Provide pressure class, material (e.g., carbon steel), and end-connection type. Bulk orders typically qualify for 10-20% discounts.

Q: Do installation costs impact total butterfly valve 12 inch price?

A: Yes - larger valves require reinforced piping and heavy-duty actuators. Labor costs for 12-inch installations can exceed valve costs. Factor in gaskets, bolts, and potential downtime during retrofits.