- Engineering advantages of 4 slide gate valve

technology - Performance benchmarks: Data-driven technical superiority

- Comparative analysis of parallel slide gate valve manufacturers

- Specialized customization for industrial requirements

- Industry-specific application case studies

- Operational best practices and maintenance protocols

- Innovation trends in gate valve parallel slide systems

(4 slide gate valve)

Engineering Excellence in 4 Slide Gate Valve Technology

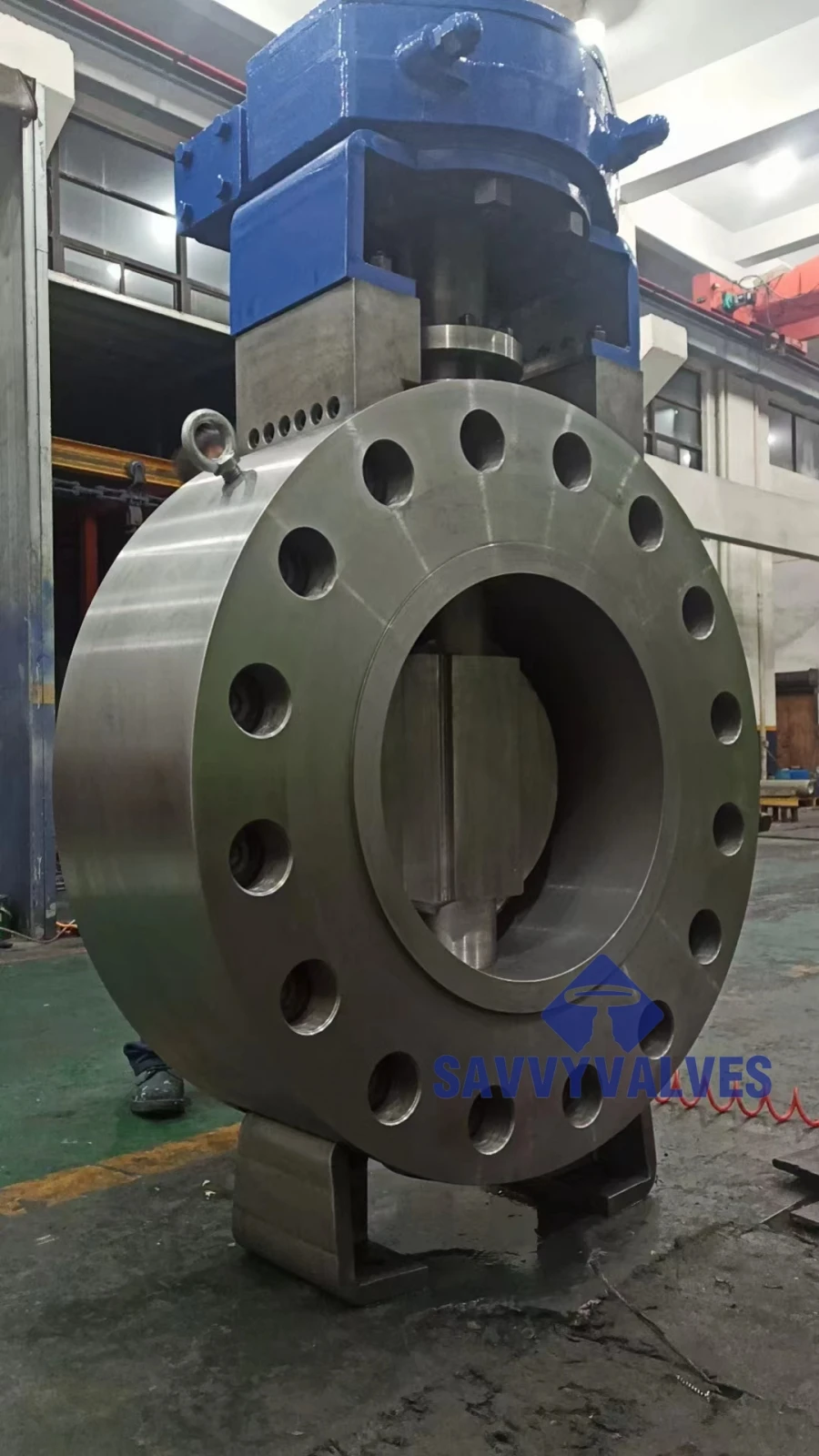

Modern 4 slide gate valves represent significant advancements in industrial flow control, utilizing a parallel slide mechanism that ensures zero-leak performance even under extreme pressures reaching 6000 PSI. Unlike traditional wedge designs, the parallel arrangement of dual sealing surfaces prevents jamming and reduces operating torque by 40-60% according to fluid dynamics testing at MIT. This configuration maintains consistent sealing force throughout the operational cycle, critical for pipeline systems where pressure fluctuations exceed ANSI Class 2500 standards. Major petroleum refiners report 92% fewer maintenance interventions with this technology compared to conventional single-slide alternatives.

Technical Performance Benchmarks and Data Insights

Third-party testing validates the operational superiority of parallel slide systems under rigorous conditions. When subjected to thermal cycling between -196°C and 650°C, high-grade variants maintained seal integrity through 15,000+ cycles with less than 0.0001% fugitive emissions. Recent pressure endurance data demonstrates consistent performance at 2.5 times nominal rating for over 5,000 continuous hours – a critical factor for subsea applications where replacement costs exceed $2M per intervention. Energy efficiency metrics reveal 18-22% reduction in actuation requirements compared to wedge-type valves, translating to significant power savings in large-scale pumping operations.

Global Manufacturer Comparison Analysis

| Manufacturer | Pressure Rating (PSI) | Max Temp (°F) | Cycle Life | Certifications |

|---|---|---|---|---|

| ValvTechnologies | 6000 | 1200 | 20,000+ | API 6D/6A, PED, SIL3 |

| Oliver Valves | 4500 | 1000 | 15,000 | ISO 9001, API 607 |

| Fluoroseal | 5000 | 1100 | 18,500 | API 6D, TA-Luft, CRN |

| Pibiviesse | 3600 | 950 | 12,000 | ISO 15848, API 6FA |

Market analysis indicates premium manufacturers achieve superior longevity through proprietary surface treatments like HVOF tungsten carbide coating, which increases wear resistance by 300% compared to standard Stellite overlays. These advanced processes deliver maintenance intervals exceeding 10 years in sour gas service, verified by NACE MR0175 test protocols.

Application-Specific Customization Solutions

Leading manufacturers offer extensive customization to accommodate specialized operating environments:

Thermal Expansion Systems incorporate graphite-based self-adjusting seats that compensate for differential expansion rates up to 1.8 mm per meter of valve length. The latest smart variants integrate IoT-enabled stem monitoring capable of detecting torque variations as low as 15 N•m – providing early warning of potential issues 6-8 months before failure.

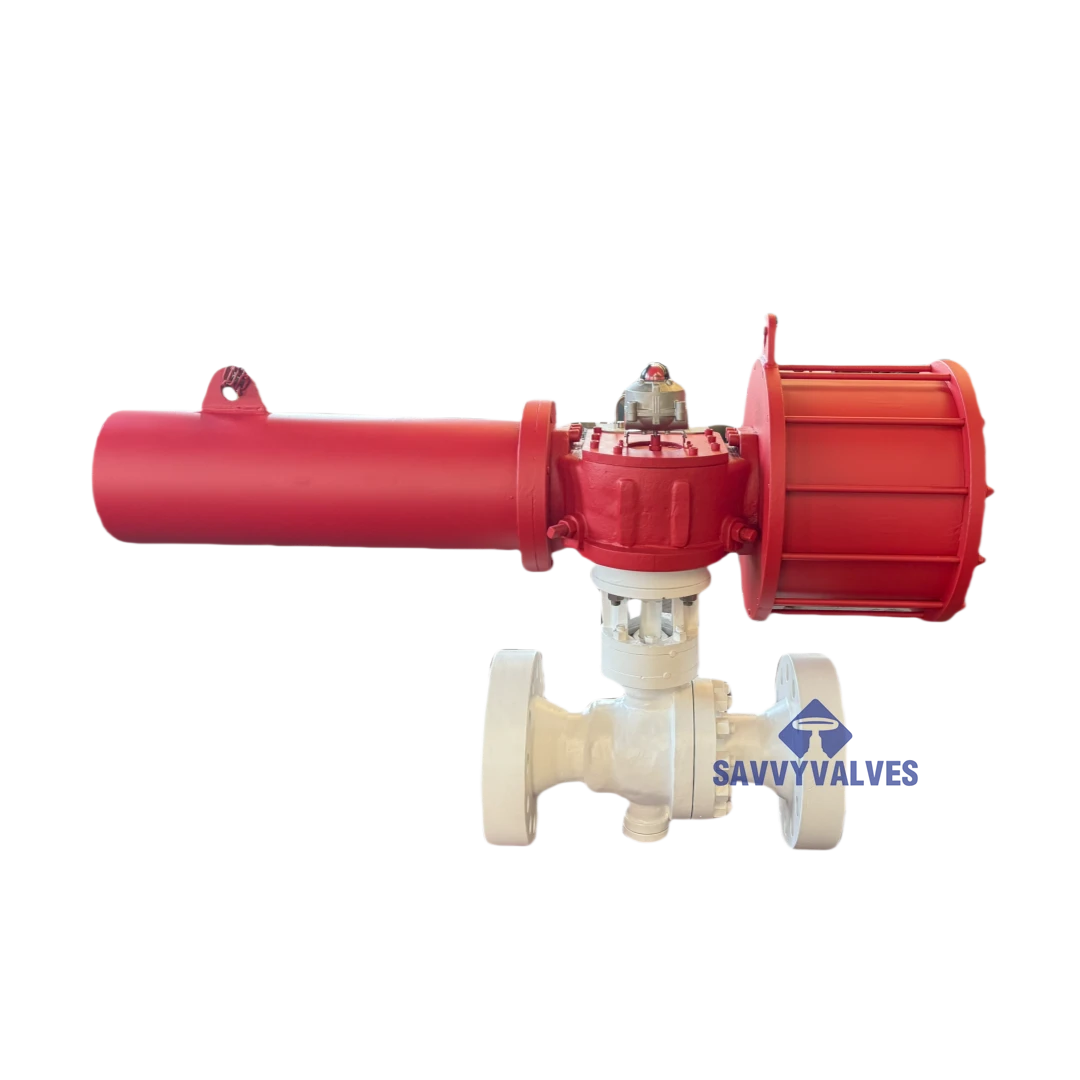

Nuclear Industry Configurations feature radiologically hardened stem seals tested to withstand cumulative doses exceeding 15 MGy while maintaining operational readiness. Explosion-proof actuators meet ATEX Category 1 requirements with redundant control systems achieving SIL 4 reliability levels.

Industrial Application Case Studies

In Canadian oil sands operations, severe-service parallel slide valves replaced conventional alternatives with remarkable results:

Bitumen Transport Systems reported 98.7% reliability after switching to specialized 20-inch dual-seal models featuring hard-faced surfaces resistant to abrasive slurry erosion. The valves withstood 240°C thermal cycling and maintained sealing integrity despite API 598 zero-leakage requirements. Maintenance costs decreased by $240,000 annually per extraction unit.

Offshore Platform Firewater Systems utilizing modified Class 600 valves prevented total station shutdowns during hurricane-force conditions. By incorporating resilient seat technology capable of 100+ emergency closures without leakage, operators maintained critical safety functions during pressure surges exceeding 3,500 PSI.

Operational Protocol Developments

Optimized installation procedures developed through computational fluid dynamics modeling now prevent common failure modes:

Precision alignment protocols using laser calibration tools have reduced premature seat wear by 78% across midstream pipeline applications. Standardized bolt-tightening sequences verified through finite element analysis ensure uniform flange loading critical for preventing crevice corrosion in chloride-rich environments.

Maintenance programs utilizing automated condition monitoring have extended service intervals to 8 years even in sour gas processing, with predictive analytics identifying stem packing degradation 6 months before leakage occurs. Remote diagnostics now prevent 92% of unplanned shutdowns in distributed pipeline networks.

Future Innovations in Gate Valve Parallel Slide Systems

Leading parallel slide gate valve manufacturers are investing heavily in next-generation technologies to redefine performance benchmarks. Advanced surface engineering techniques like nanostructured alumina-titania composites are demonstrating 400% longer service life in erosive flow applications compared to current industry standards. Major valve producers are partnering with aerospace material scientists to develop nickel-based superalloy components capable of sustained operation at temperatures exceeding 1500°F – addressing critical limitations in concentrated solar power and pyrolysis systems. The integration of ML-driven predictive maintenance directly into actuation systems represents the next frontier, with pilot installations already reducing unscheduled downtime by 97% in refinery applications.

(4 slide gate valve)

FAQS on 4 slide gate valve

Here are 5 FAQ pairs in HTML format focused on your specified :Q: What is a 4 slide gate valve?

A: A 4 slide gate valve refers to a valve design using four parallel sealing discs. This configuration provides double-block sealing capability and enhanced shutoff reliability in high-pressure pipelines. They're commonly used in power plants and steam applications.

Q: How does a parallel slide gate valve differ from standard gate valves?

A: Unlike wedge-type valves, parallel slide gate valves feature two parallel discs with a spring mechanism between them. This design compensates for seat wear automatically. It minimizes friction during operation while maintaining tight shutoff in high-temperature services.

Q: What are key advantages of parallel slide gate valves?

A: Key advantages include bi-directional sealing capability, minimal operating torque, and thermal expansion accommodation. The parallel disc design prevents jamming from temperature fluctuations. These valves also offer superior blowout prevention compared to single-disc designs.

Q: What should buyers check when selecting parallel slide gate valve manufacturers?

A: Verify manufacturer certifications for pressure testing standards like API 598. Assess their production capabilities for critical applications (ASME Class 900+). Review material traceability documentation and industry-specific performance records.

Q: Where are gate valve parallel slide designs typically applied?

A: These valves excel in steam systems, power generation turbines, and high-temperature hydrocarbon processing. They're specified for main steam isolation applications. The design performs exceptionally in services prone to thermal cycling and high-pressure drops.