Kayu Panggangan Grill Anda Pemanggang Pelet

SPESIFIKASI CONTOH

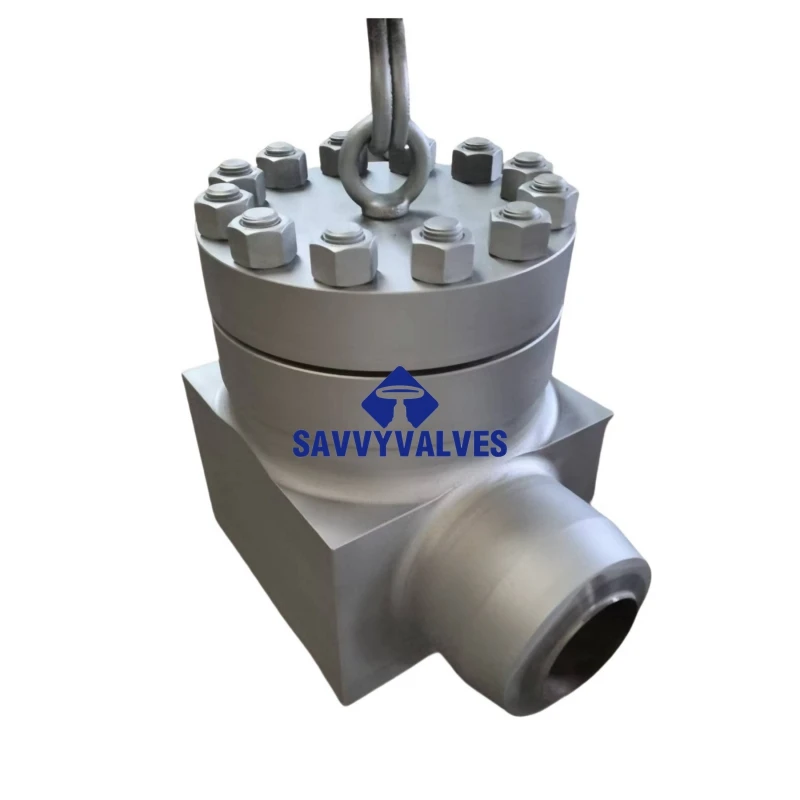

SAIZ: DN20

PENILAIAN: PN420

TAMAT: BW SEPERTI B16.25

SUHU: -196 ℃

BADAN DAN BONNET : ASTM A182 F304

PALAM: ASTM A182 F304+HF

SEAT: PCTFE ATAU HF METAL

PENGAKUAN: SPRING DIMUAT

UMUM

Saiz: 1/8″~24″.

Penilaian Tekanan: 150LB~4500LB, PN6~PN750

Suhu Reka Bentuk: -196℃~800℃.

Aplikasi am: CNG, LNG, LPG, CO2, N2, tugas kriogenik lain. Kewajipan terma STEAM.

REKA BENTUK

Reka Bentuk & Pembuatan: BS 6364, API 6D, ASME B16.34 adalah asas, norma lain boleh digunakan mengikut pesanan.

Dimensi F HINGGA F: API 6D, ASME B16.10, BS EN 558

Sambungan: ASME B16.25, ASME B16.5, ASME B16.47, EN 1092, JIS 5K-20K. BW, RTJ tersedia.

Reka bentuk keselamatan: kalis api

BAHAN AM

BADAN: ASTM A182 F304/F316/F304L/F316L/F51/F53, MONEL K400/K500, H276,INCONEL 625/718

PALAM: ASTM A182 F304, F316

SEAT: PCTFE, PEEK, HF METAL

OPERATOR: SPRING MUAT

BAHAN KHAS LAIN ADA UNTUK DISESUAIKAN.

UJIAN

Pemeriksaan dan norma kelulusan: API598, API6D, BS6364.

KAWALAN KUALITI:

100% Analisis kimia dan ujian mekanikal dengan bahan mentah setiap nombor haba.

Ujian DPT 100% dengan tuangan, sebahagiannya ujian MT atau UT, RT sentiasa tersedia jika diperlukan.

Ujian hidraulik 100% dengan shell dan meterai dan ujian udara tekanan rendah.

JAMINAN:

SAVVY VALVES menyediakan hayat perkhidmatan sekurang-kurangnya 12 bulan, alat ganti percuma dan arahan penyelenggaraan akan diberikan apabila diperlukan.

The CNG LNG cryogenic piston lifting check valve free forged is engineered to ensure backflow prevention in ultra-low temperature environments commonly found in liquefied gas systems such as CNG and LNG applications. Its piston-type lifting mechanism provides precise, responsive flow control and seals tightly upon flow reversal, which is critical for protecting downstream equipment in cryogenic conditions. The free forged body enhances the valve’s structural strength, pressure resistance, and resistance to thermal shock, which is vital for maintaining performance at temperatures as low as -196°C. Designed with an extended bonnet, it isolates the stem and packing from direct contact with cryogenic fluids, minimizing leakage risks. This valve is widely used in LNG terminals, gas liquefaction plants, and cryogenic storage tanks where safety, durability, and zero leakage are non-negotiable. Its compact size, low cracking pressure, and robust sealing performance make it ideal for high-integrity gas systems under extreme conditions.

Jika anda berminat dengan produk kami, anda boleh memilih untuk meninggalkan maklumat anda di sini, dan kami akan menghubungi anda sebentar lagi.