Kayu Panggangan Grill Anda Pemanggang Pelet

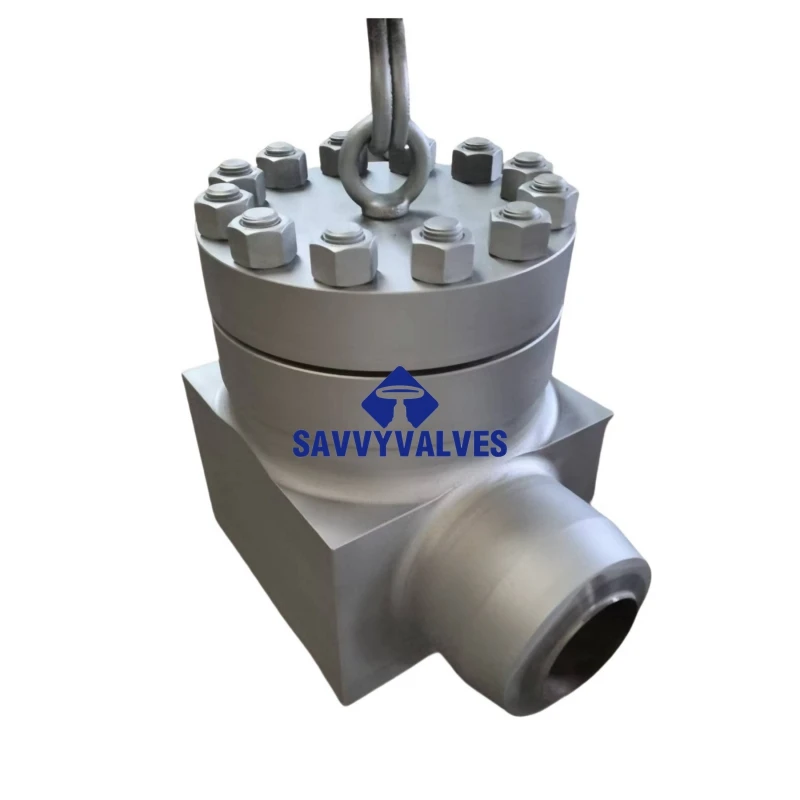

GAMBAR MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH

SAIZ: 1″

PENILAIAN: 150LB

BADAN DAN BONNET : ASTM A105

CAKERA: ASTM A105+STELLITE 6

SPRING: INCONEL X-750

KEDUDUKAN: ASTM A105+STELLITE 6

JENIS LIFT/PISTON

Saiz: 1/8″~4″.

Penilaian Tekanan: 150LB~4500LB

Suhu Reka Bentuk: -196℃~800℃.

Aplikasi umum: air, minyak, gas

Reka Bentuk & Pembuatan: API 594, API 6D, ASME B16.34,API 602 adalah asas, norma lain boleh digunakan mengikut pesanan.

Dimensi F HINGGA F: API 6D, API 594, ASME B16.10, BS EN 558

Sambungan: RF AS PER ASME B16.5, ASME B16.47, EN 1092, JIS 5K-20K. BW, RTJ tersedia.

Struktur : CAKERA ANGKAT CAKERA PISTON, BERMUAT SPRING, BOLTED BONNET PRESSURE SEAL BONNET BONNET KIMPAL, PORT PENUH ATAU REDUCE PORT

BAHAN TYPICAL

BADAN DAN BONNET: ASTM A105, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800,/C95800 H-276, INCONEL 625/718.

CAKERA: ASTM A105, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, INKEL-MONEL 625/718 + KERAS MUKA

SPRING: INCONEL X-750

KEDUDUKAN:ASTM A105, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, INKEL-2000, INKKEL 625/718+KERAS MUKA.

BAHAN KHAS LAIN ADA UNTUK DISESUAIKAN.

UJIAN

Pemeriksaan dan norma kelulusan: API598, API6D.

KAWALAN KUALITI:

100% Analisis kimia dan ujian mekanikal dengan bahan mentah setiap nombor haba.

Ujian DPT 100% dengan tuangan, sebahagiannya ujian MT atau UT, RT sentiasa tersedia jika diperlukan.

Ujian hidraulik 100% dengan shell dan meterai dan ujian udara tekanan rendah.

JAMINAN:

SAVVY VALVES menyediakan hayat perkhidmatan sekurang-kurangnya 12 bulan, alat ganti percuma dan arahan penyelenggaraan akan diberikan apabila diperlukan.

The API 602 Pattern Forged Lifting Check Valve is designed for high-pressure, high-temperature applications in compact piping systems, particularly in industries like oil and gas, power generation, and chemical processing. Built to conform with API 602 standards, this valve features a compact, forged body for enhanced strength and durability in critical service conditions. The lifting check mechanism allows the disc to rise with forward flow and automatically seat with reverse flow, preventing backflow and protecting pumps and equipment. Its forged construction ensures better grain structure and resistance to stress corrosion, while the tight sealing performance minimizes leakage and pressure drop. Typically available in a variety of materials and end connections, this valve is suited for use in small-bore piping with severe operating conditions. The API 602 pattern emphasizes reliability, space efficiency, and long-term performance, making it a trusted choice for engineers and plant operators requiring robust flow control in demanding environments.

Jika anda berminat dengan produk kami, anda boleh memilih untuk meninggalkan maklumat anda di sini, dan kami akan menghubungi anda sebentar lagi.