Kayu Panggangan Grill Anda Pemanggang Pelet

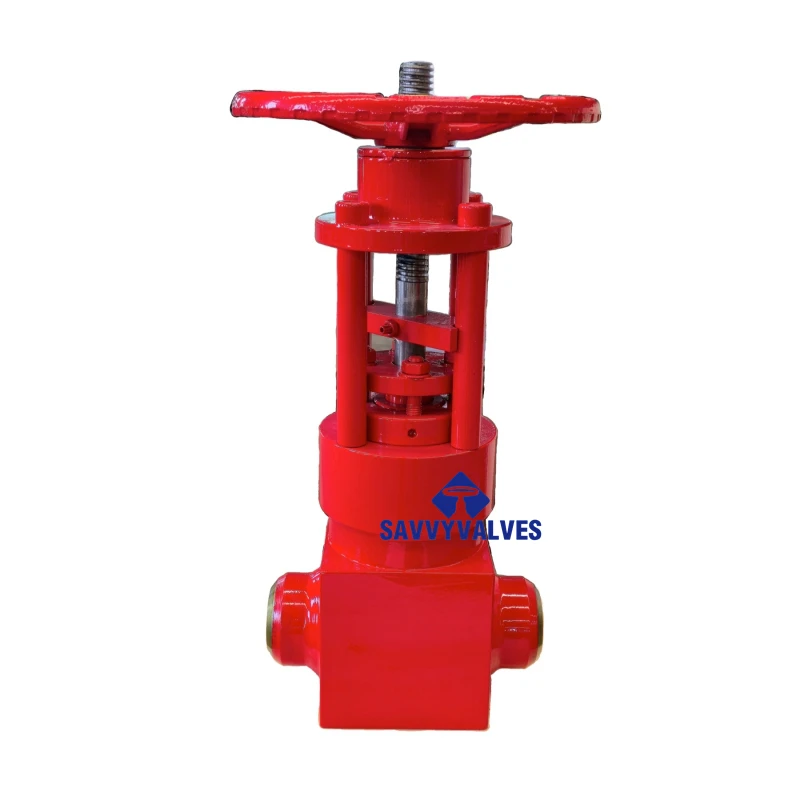

GAMBAR MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH

SAIZ: 1″

PENILAIAN: 800LB

TAMAT: SW SEPERTI ASME B16.11

SUHU: -196 ℃

BADAN DAN BONNET : ASTM A182 F304

BAJI: PEPEJAL ASTM A182 F304+HF

STEM: ASTM A182 F304

KEDUDUKAN: HF METAL

PENGAKUAN: RODA TANGAN

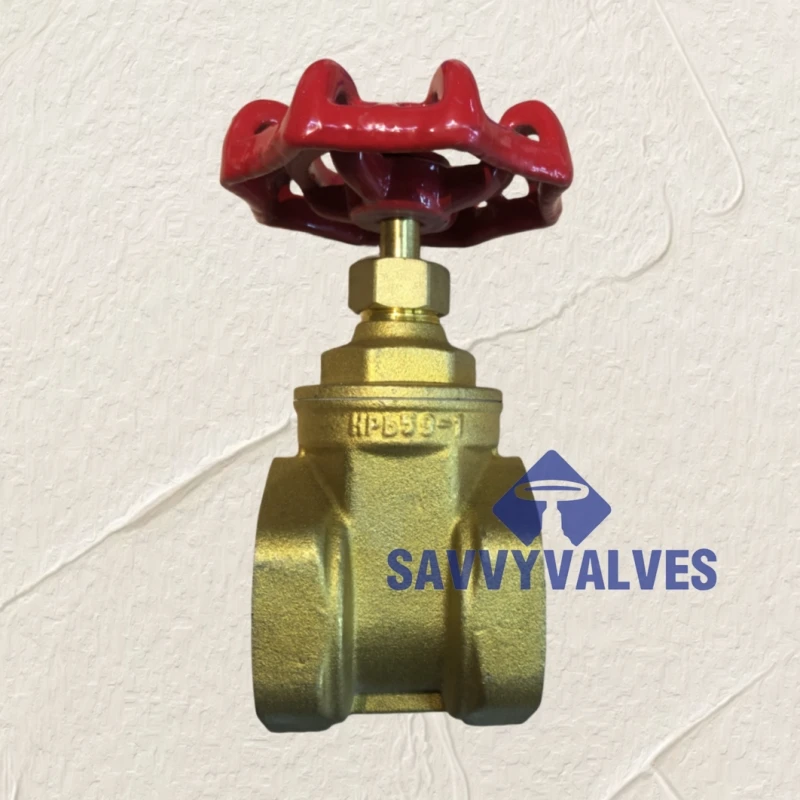

UMUM

Saiz: 1/8″~4″.

Penilaian Tekanan: 150LB~4500LB, PN6~PN750

Suhu Reka Bentuk: -196℃~800℃.

Aplikasi am: CNG, LNG, LPG, CO2, N2, tugas kriogenik lain. Kewajipan terma STEAM.

Reka Bentuk & Pembuatan: BS 6364, API 6D, ASME B16.34, API 602 adalah asas, norma lain boleh digunakan mengikut pesanan.

Dimensi F HINGGA F: API 6D, ASME B16.10, BS EN 558

Sambungan: ASME B16.11, ASME B16.25, ASME B16.5, EN 1092, JIS 5K-20K. RF, RTJ tersedia.

Reka bentuk keselamatan: kalis api

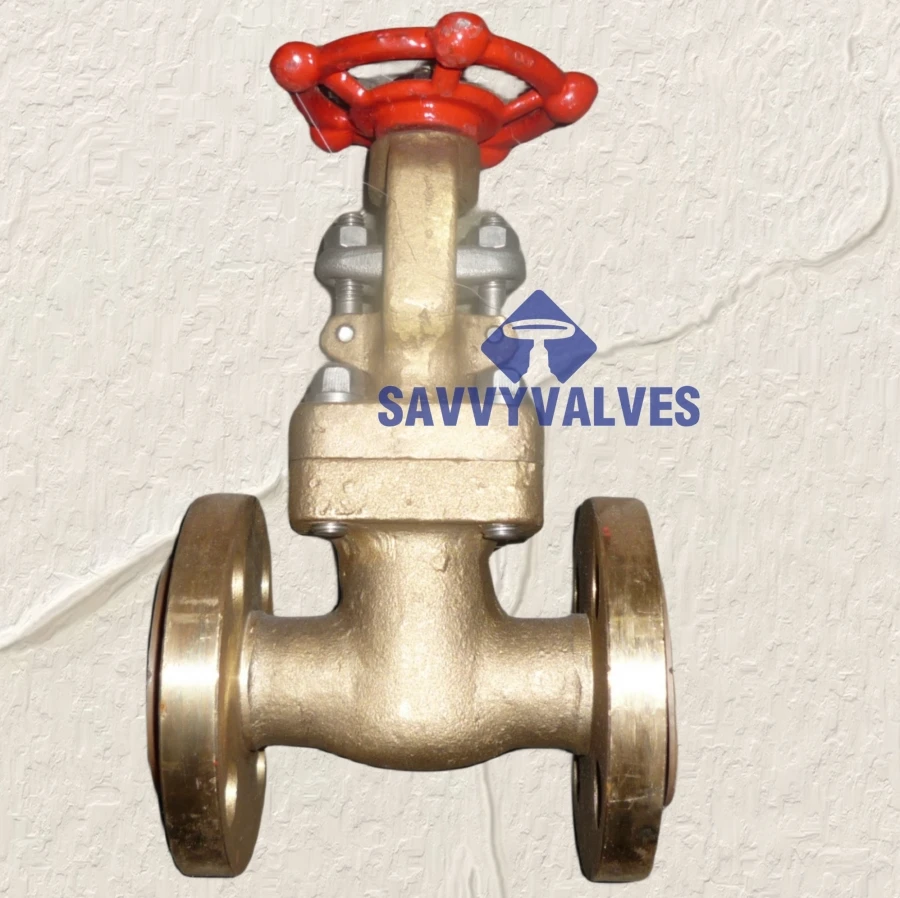

BAHAN AM

BADAN: ASTM A182 F304/F316/F304L/F316L/F51/F53, MONEL K400/K500, H276,INCONEL 625/718

PALAM: ASTM A182 F304, F316

SEAT: PCTFE, PEEK, HF METAL

OPERATOR: SPRING MUAT

BAHAN KHAS LAIN ADA UNTUK DISESUAIKAN.

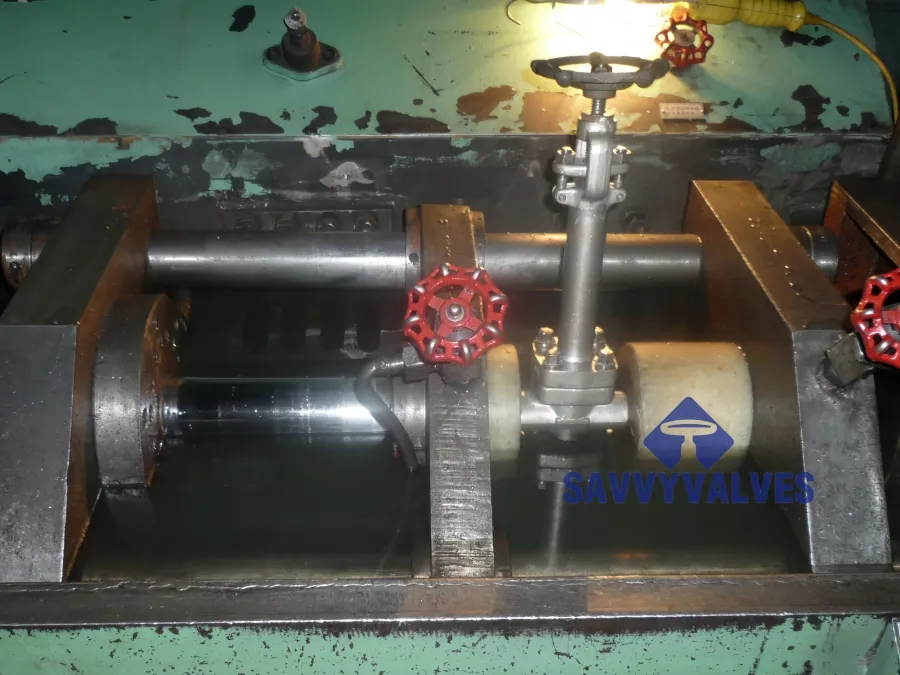

UJIAN

Pemeriksaan dan norma kelulusan: API598, API6D, BS6364.

KAWALAN KUALITI:

100% Analisis kimia dan ujian mekanikal dengan bahan mentah setiap nombor haba.

Ujian DPT 100% dengan tuangan, sebahagiannya ujian MT atau UT, RT sentiasa tersedia jika diperlukan.

Ujian hidraulik 100% dengan shell dan meterai dan ujian udara tekanan rendah.

JAMINAN:

SAVVY VALVES menyediakan hayat perkhidmatan sekurang-kurangnya 12 bulan, alat ganti percuma dan arahan penyelenggaraan akan diberikan apabila diperlukan.

The CNG LNG LPG pattern forged cryogenic gate valve is specifically engineered for ultra-low temperature applications, where secure shut-off and reliable operation are critical. Designed for use in systems handling liquefied gases like CNG, LNG, and LPG, this valve features a forged body that ensures superior strength, uniform grain structure, and excellent resistance to thermal shock. The cryogenic extension bonnet keeps stem packing away from direct exposure to cold media, reducing the risk of frosting and leakage. Its full bore gate design offers minimal flow resistance and ensures unobstructed fluid passage, which is essential in high-capacity cryogenic transfer lines. The valve’s materials and design are compliant with international cryogenic standards to guarantee safety and durability under extreme conditions. With tight shut-off capability, long service life, and suitability for both manual and automated actuation, it’s an ideal choice for LNG terminals, gas processing plants, and cryogenic storage systems.

Jika anda berminat dengan produk kami, anda boleh memilih untuk meninggalkan maklumat anda di sini, dan kami akan menghubungi anda sebentar lagi.