La tua griglia cuoce a legna Griglia a pellet

SPECIFICHE DEL CAMPIONE

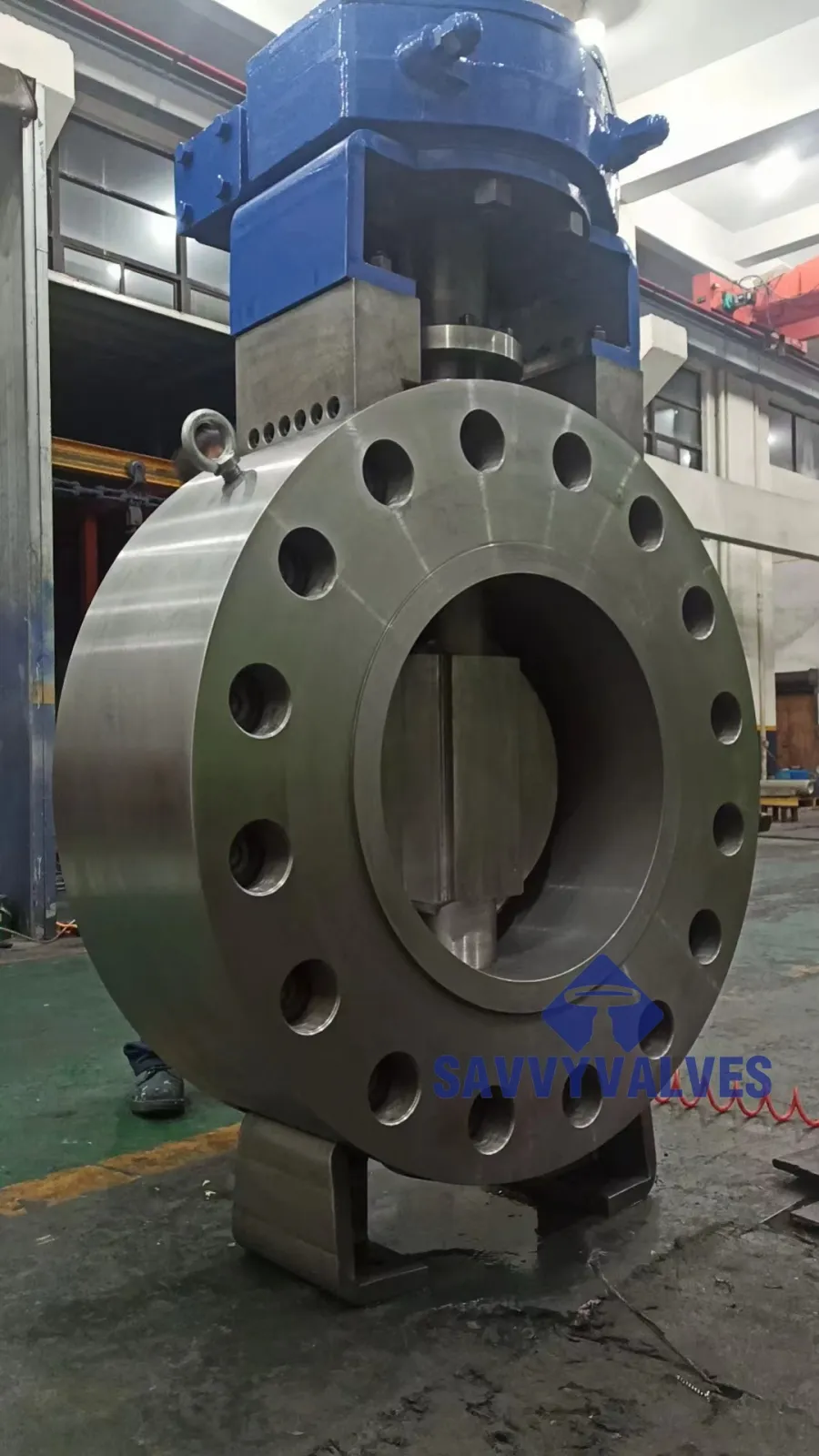

TAGLIA: 26″

VALUTAZIONE: 1500 LB

CORPO: ASTM A105N

DISCO: ASTM A182 F316

GIOGO ESTESO: ASTM A182 F5

STEM: SS416

SEDILE: ASTM A182 F316

GUARNIZIONE: SS316+GRAFITE LAMINATA

ATTUAZIONE: RIDUTTORE

SPECIFICHE GENERALI PROGETTATE

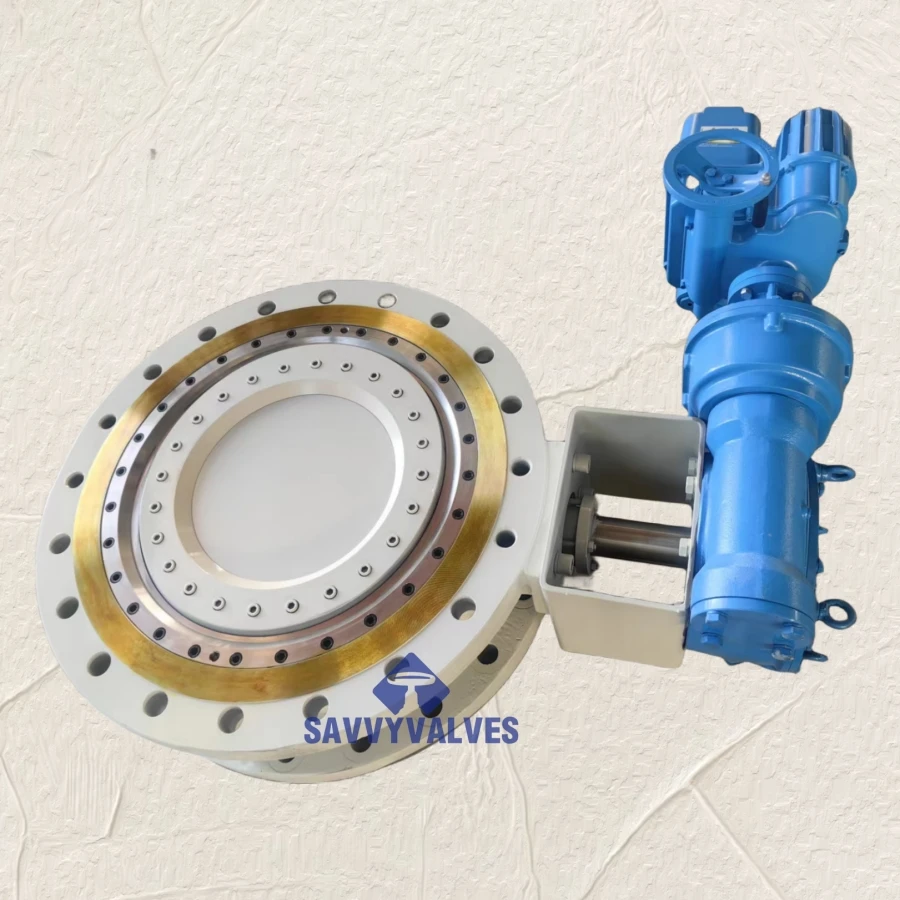

Dimensioni: 2″~144″.

Pressione nominale: 150LB~4500LB

Temperatura di progetto: MAX. 800℃.

Applicazioni generali: VAPORE.

Progettazione e produzione: API 609, EN 593 sono norme di base, ASME B16.34, altre norme potrebbero essere utilizzate in base agli ordini.

Dimensioni da F a F: API 609, ASME B16.10, BS EN 558

Connessione: ASME B16.25, EN 1092, JIS 5K-20K. Sono disponibili RF, RTJ.

Design di sicurezza: stelo anti-esplosione. Piastra termica.

ELENCO DEI MATERIALI TIPICI

CORPO: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

DISCO: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

GIOGO ESTESO: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

SEDILE: STELLITE NO.6 HF

GUARNIZIONE: SS316+GRAFITE LAMINATA

OPERATORE: RIDUTTORE

SONO DISPONIBILI ALTRI MATERIALI SPECIALI DA PERSONALIZZARE.

TEST E ISPEZIONE

Norma di ispezione e approvazione: API598, API6D.

CONTROLLO QUALITÀ

Analisi chimica e test meccanici al 100% con materie prime di ogni colata.

Prova DPT al 100% con i getti, in parte prova MT o UT, RT sempre disponibile se necessario.

Prova idraulica al 100% con guscio e guarnizione e prova dell'aria a bassa pressione.

GARANZIA

Le valvole SAVVY VALVES garantiscono una durata di almeno 12 mesi e, se necessario, vengono forniti pezzi di ricambio gratuiti e istruzioni per la manutenzione.

La valvola a farfalla a triplo eccentrico per impieghi termici/alte temperature in acciaio forgiato è specificamente progettata per ambienti con temperature e pressioni estreme, il che la rende la scelta ideale per applicazioni nella produzione di energia, nella raffinazione del petrolio, nell'industria chimica e nei sistemi a vapore. Il suo design a triplo eccentrico garantisce un attrito minimo tra il disco e la sede, consentendo una chiusura ermetica anche dopo una prolungata esposizione a sollecitazioni termiche. Il corpo in acciaio forgiato migliora la resistenza meccanica e termica, consentendo alla valvola di funzionare in modo affidabile in cicli continui ad alta temperatura. Questa valvola è ideale per il controllo di vapore surriscaldato, gas caldi e fluidi aggressivi, dove i materiali standard delle valvole si degraderebbero. Il design di tenuta metallo su metallo previene inoltre la deformazione della sede e le perdite in caso di elevata pressione differenziale. Grazie alla sua struttura robusta, all'eccellente capacità di tenuta e alla lunga durata, questa valvola offre prestazioni superiori in sistemi industriali esigenti in cui temperatura e sicurezza sono fattori critici.

Se sei interessato ai nostri prodotti, puoi scegliere di lasciare qui i tuoi dati e ti contatteremo al più presto.