Ihr Grill Grills Holz Pelletgrill

BEISPIELSPEZIFIKATIONEN

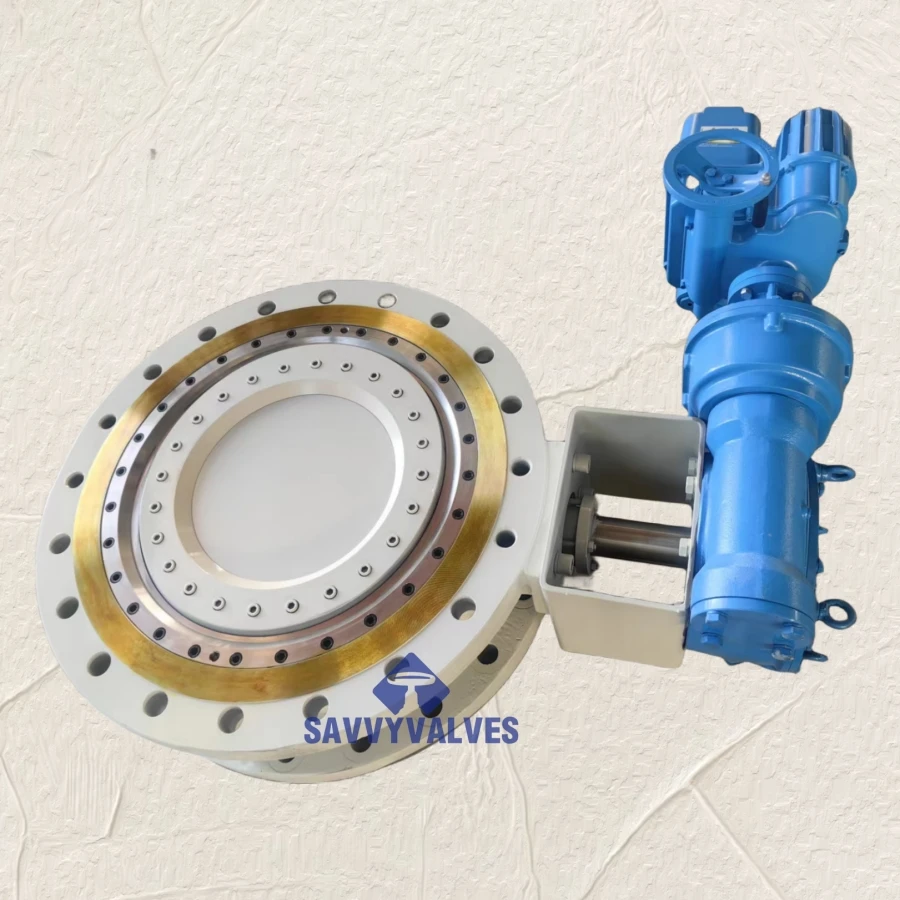

GRÖSSE: DN800

BEWERTUNG: PN25

KÖRPER: CS

SCHEIBE: CF8

VERLÄNGERTES JOCH: ASTM A182 F5

VORBAU: SS416

SITZ: ASTM A182 F5 AUSTAUSCHBAR.

DICHTUNG: SS316+GRAPHIT LAMINIERT

BETÄTIGUNG: GETRIEBE

Größe: 2″~144″.

Druckbewertung: 150LB~4500LB

Auslegungstemperatur: MAX. 800 °C.

Allgemeine Anwendungen: STEAM.

Design und Herstellung: API 609, EN 593 sind grundlegend, ASME B16.34, andere Normen können je nach Bestellung verwendet werden.

F BIS F-Abmessungen: API 609, ASME B16.10, BS EN 558

Anschluss: ASME B16.25, EN 1092, JIS 5K-20K. RF, RTJ sind verfügbar.

Sicherheitsdesign: Ausblassicherer Schaft. Wärmeplatte.

TYPISCHE MATERIALLISTE

KÖRPER: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

SCHEIBE: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

VERLÄNGERTES JOCH: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

SCHAFT: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

SITZ: STELLITE NR. 6 HF

DICHTUNG: SS316+GRAPHIT LAMINIERT

BETREIBER: GETRIEBE

WEITERE SPEZIELLE MATERIALIEN SIND ZUR ANPASSUNG VERFÜGBAR.

TEST UND INSPEKTION

Prüf- und Zulassungsnorm: API598, API6D.

QUALITÄTSKONTROLLE

100 % chemische Analyse und mechanischer Test mit Rohstoffen jeder Wärmenummer.

100% DPT-Prüfung bei den Gussteilen, teilweise MT- oder UT-Prüfung, RT ist bei Bedarf immer vorhanden.

100 % Hydrauliktest mit Schale und Dichtung sowie Niederdrucklufttest.

GARANTIE

SAVVY VALVES bieten eine Lebensdauer von mindestens 12 Monaten. Bei Bedarf werden kostenlose Ersatzteile und Wartungsanleitungen bereitgestellt.

The fabricated triple offset butterfly valve for thermal duty is engineered to handle extreme temperatures in demanding applications such as power plants, refineries, and high-temperature process systems. Its triple offset design eliminates seat wear during operation by ensuring the disc moves away from the seat without scraping, enabling bubble-tight shutoff even under thermal stress. The fabricated body construction allows for customized designs and weight reduction while maintaining structural strength. This valve is ideal for thermal cycles because it resists deformation and provides consistent performance across temperature fluctuations. Metal-to-metal seating offers excellent resistance to heat, pressure, and corrosion, extending the valve’s service life. In thermal duty systems, where precision and durability are critical, this valve delivers superior sealing, reduced torque, and minimal maintenance, making it a reliable choice for high-temperature flow control.

Wenn Sie an unseren Produkten interessiert sind, können Sie Ihre Informationen hier hinterlassen und wir werden uns in Kürze mit Ihnen in Verbindung setzen.