Panggangan Anda Memanggang Kayu Panggang Pelet

SPESIFIKASI SAMPEL

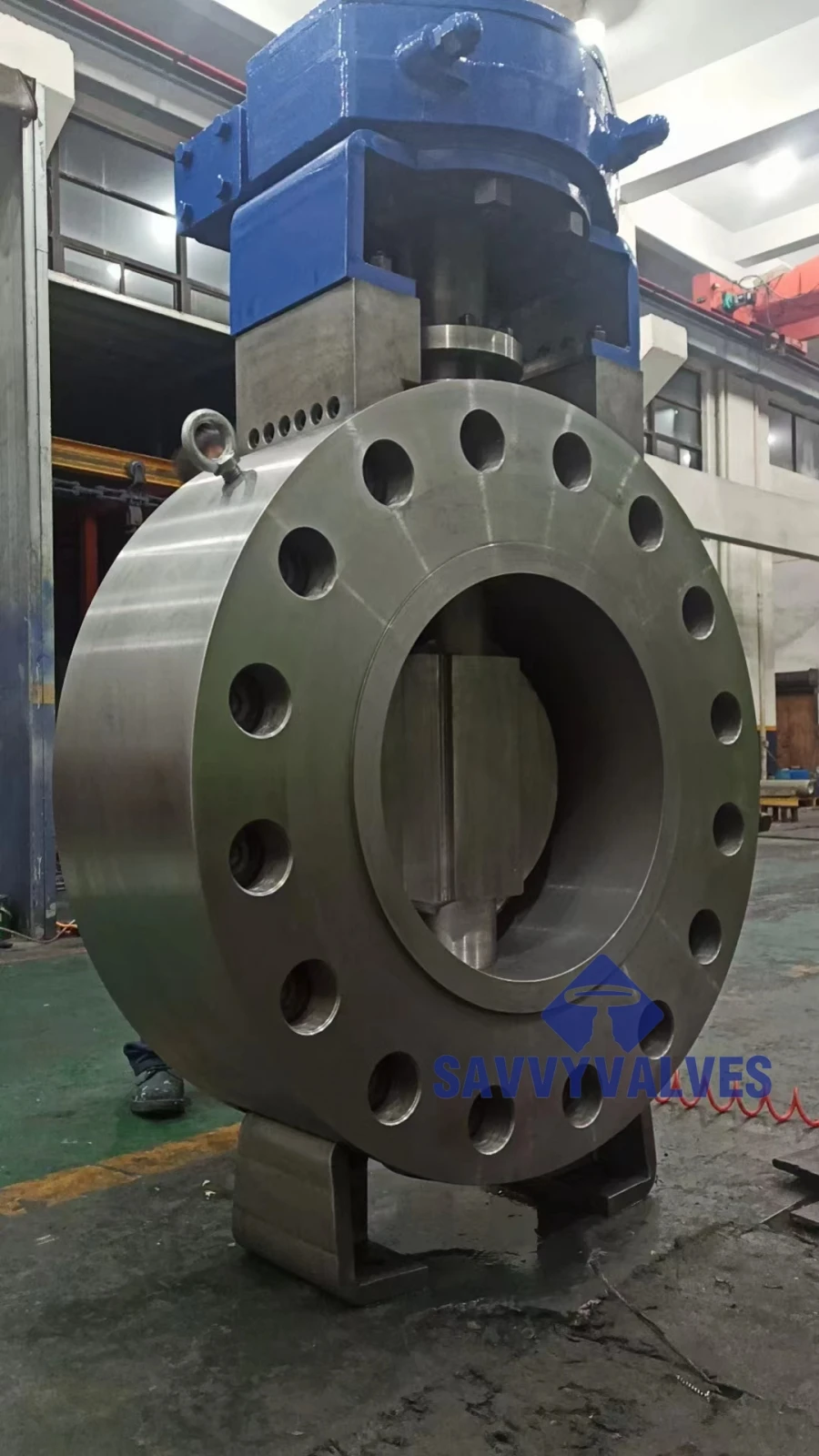

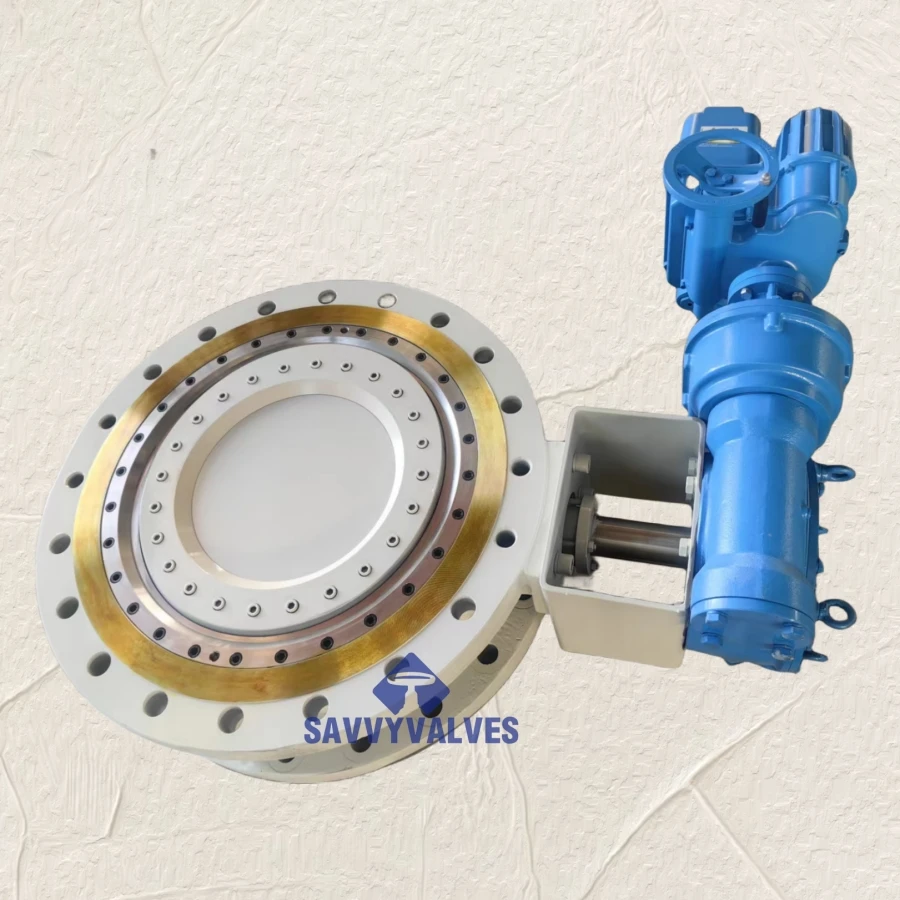

UKURAN: DN800

PERINGKAT: PN25

BADAN: CS

CAKRAM: CF8

KUK YANG DIPERPANJANG: ASTM A182 F5

BATANG: SS416

KURSI: ASTM A182 F5 DAPAT DIGANTI.

SEGEL: SS316 + LAMINASI GRAFIT

PENGGERAK: UNIT RODA GIGI

Ukuran: 2″~144″.

Peringkat Tekanan: 150LB~4500LB

Design Temperature: MAX. 800℃.

General applications: STEAM.

Design & Manufacture: API 609, EN 593 are basic, ASME B16.34 ,other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: ASME B16.25, EN 1092, JIS 5K-20K. RF, RTJ are available.

Safety design: anti-blow out stem.thermal plate.

DAFTAR BAHAN UMUM

BODY: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

DISC: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

EXTENDED YOKE: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

KURSI: STELLITE NO.6 HF

SEGEL: SS316 + LAMINASI GRAFIT

OPERATOR: UNIT GIGI

BAHAN KHUSUS LAINNYA TERSEDIA UNTUK DISESUAIKAN.

UJI DAN INSPEKSI

Norma inspeksi dan persetujuan: API598, API6D.

KONTROL KUALITAS

100% Analisis kimia dan uji mekanis dengan bahan baku setiap nomor panas.

Uji DPT 100% dengan coran, sebagian uji MT atau UT, RT selalu tersedia jika diperlukan.

Uji hidrolik 100% dengan cangkang dan segel serta uji udara bertekanan rendah.

JAMINAN

SAVVY VALVES memberikan masa pakai minimal 12 bulan, suku cadang gratis dan petunjuk perawatan akan diberikan bila diperlukan.

The fabricated triple offset butterfly valve for thermal duty is engineered to handle extreme temperatures in demanding applications such as power plants, refineries, and high-temperature process systems. Its triple offset design eliminates seat wear during operation by ensuring the disc moves away from the seat without scraping, enabling bubble-tight shutoff even under thermal stress. The fabricated body construction allows for customized designs and weight reduction while maintaining structural strength. This valve is ideal for thermal cycles because it resists deformation and provides consistent performance across temperature fluctuations. Metal-to-metal seating offers excellent resistance to heat, pressure, and corrosion, extending the valve’s service life. In thermal duty systems, where precision and durability are critical, this valve delivers superior sealing, reduced torque, and minimal maintenance, making it a reliable choice for high-temperature flow control.

Jika Anda tertarik dengan produk kami, Anda dapat memilih untuk meninggalkan informasi Anda di sini, dan kami akan segera menghubungi Anda.