Tu Parrilla Parrillas De Madera Parrilla de pellets

ESPECIFICACIONES DE MUESTRA

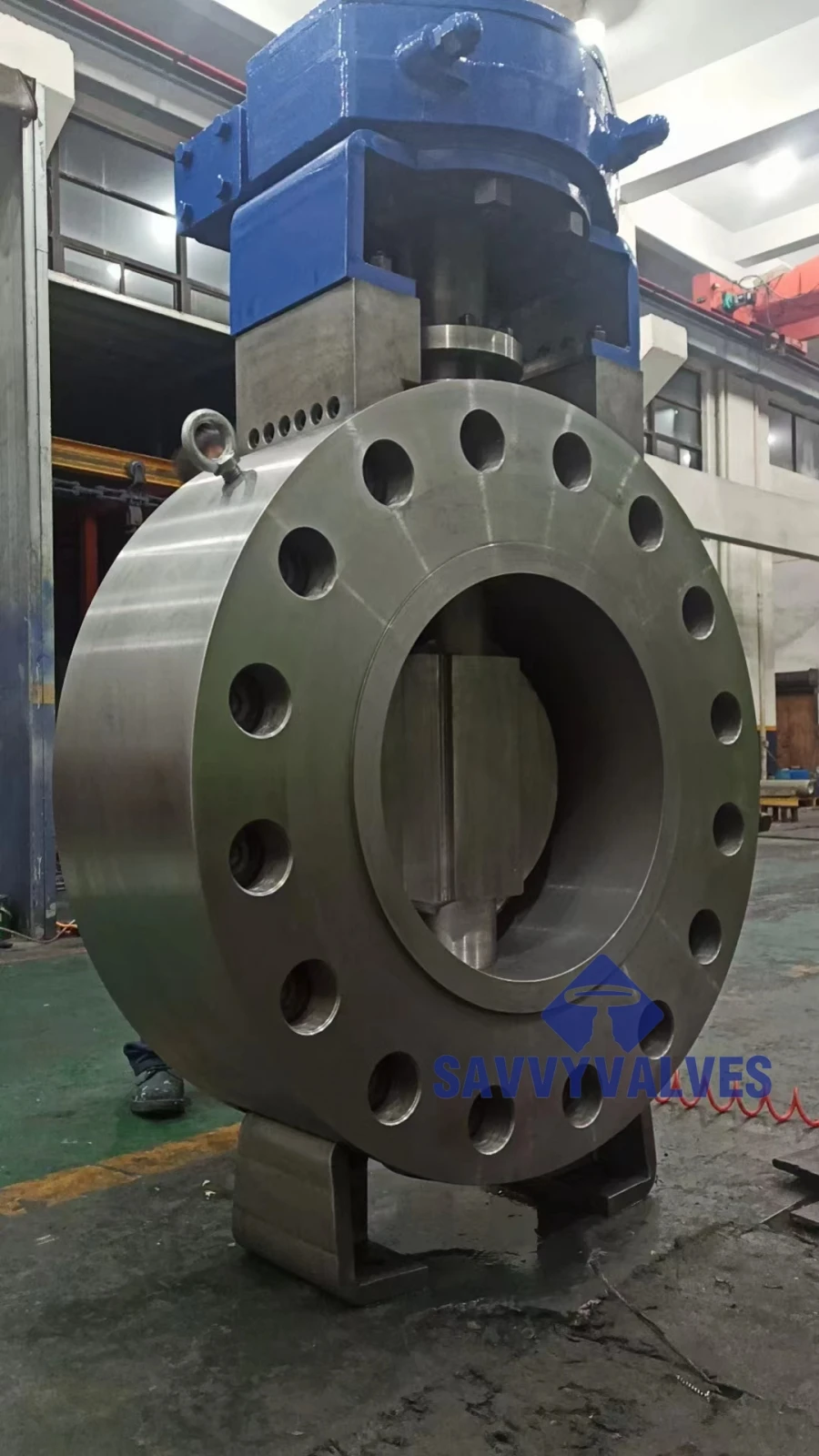

TAMAÑO: DN800

CLASIFICACIÓN: PN25

CUERPO: CS

DISC: CF8

YUGO EXTENDIDO: ASTM A182 F5

STEM: SS416

ASIENTO: ASTM A182 F5 REEMPLAZABLE.

SEAL: SS316+GRAPHITE LAMINATED

ACCIONAMIENTO: UNIDAD DE REDUCCIÓN

Tamaño: 2″~144″.

Clasificación de presión: 150LB~4500LB

Design Temperature: MAX. 800℃.

General applications: STEAM.

Design & Manufacture: API 609, EN 593 are basic, ASME B16.34 ,other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: ASME B16.25, EN 1092, JIS 5K-20K. RF, RTJ are available.

Safety design: anti-blow out stem.thermal plate.

LISTA DE MATERIALES TÍPICOS

BODY: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

DISC: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

EXTENDED YOKE: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

VÁSTAGO: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

ASIENTO: STELLITE NO.6 HF

SEAL: SS316+GRAPHITE LAMINATED

OPERADOR: UNIDAD DE REDUCCIÓN

HAY OTROS MATERIALES ESPECIALES DISPONIBLES PARA PERSONALIZAR.

PRUEBA E INSPECCIÓN

Norma de inspección y aprobación: API598, API6D.

CONTROL DE CALIDAD

100% Análisis químico y pruebas mecánicas con materias primas de cada número de colada.

Prueba DPT al 100% con las piezas fundidas, prueba parcialmente MT o UT, RT siempre está disponible si es necesario.

Prueba hidráulica al 100% con carcasa y sello y prueba de aire a baja presión.

GARANTÍA

Las válvulas SAVVY brindan una vida útil de al menos 12 meses, se proporcionarán repuestos gratuitos e instrucciones de mantenimiento cuando sea necesario.

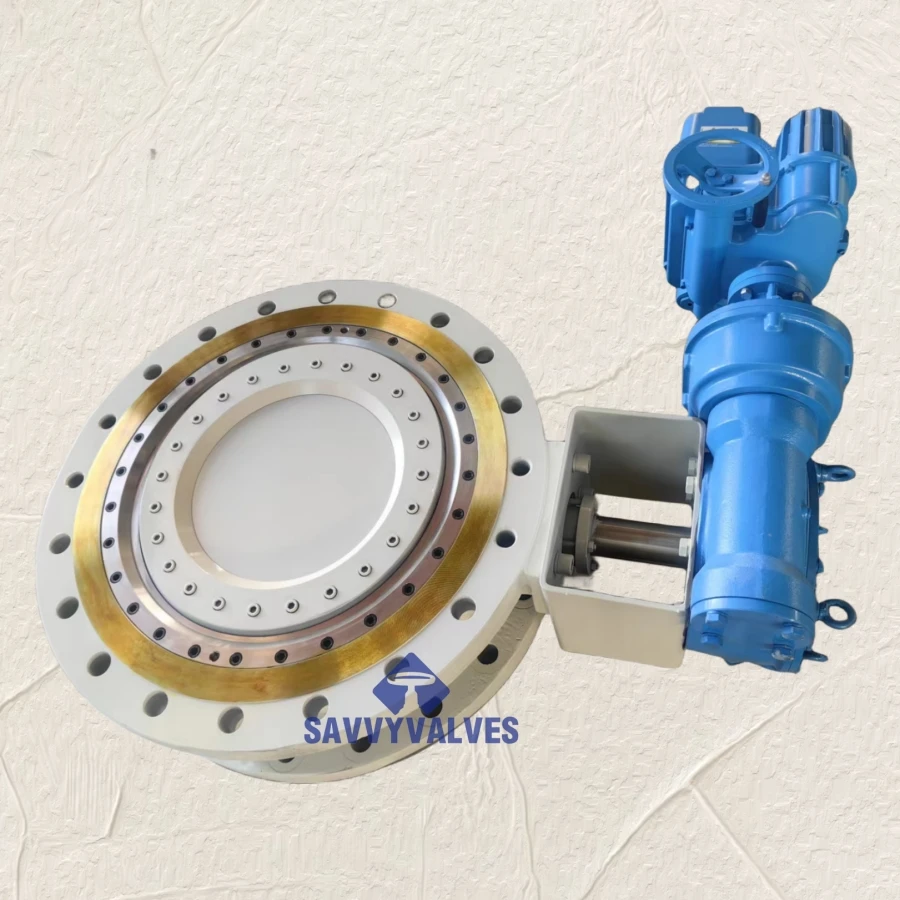

The fabricated triple offset butterfly valve for thermal duty is engineered to handle extreme temperatures in demanding applications such as power plants, refineries, and high-temperature process systems. Its triple offset design eliminates seat wear during operation by ensuring the disc moves away from the seat without scraping, enabling bubble-tight shutoff even under thermal stress. The fabricated body construction allows for customized designs and weight reduction while maintaining structural strength. This valve is ideal for thermal cycles because it resists deformation and provides consistent performance across temperature fluctuations. Metal-to-metal seating offers excellent resistance to heat, pressure, and corrosion, extending the valve’s service life. In thermal duty systems, where precision and durability are critical, this valve delivers superior sealing, reduced torque, and minimal maintenance, making it a reliable choice for high-temperature flow control.

Si está interesado en nuestros productos, puede optar por dejar su información aquí y nos pondremos en contacto con usted en breve.