Drosselventile

-

Größe: 2" (2 Zoll)

Druckbewertung: 10.000 PSI (entspricht API 6A)

Antrieb: Motorantrieb

Anschlussende: RTJ-Flansch (API 6BX)

Konfiguration: Winkelmuster, ausgewogene Käfigverkleidungen

Oberflächenbeschaffenheit: Sandgestrahlt und epoxidbeschichtet

Temperaturbereich: -29 °C bis 425 °C

-

Kurzbeschreibung: Größe: 1 Zoll. Nennleistung: 10000 PSI, 10K. Materialien: ASTM A182 A105 Gehäuse und Haube. ASTM A182 F105+TCC-Scheibe. ASTM A182 F6A Schaft. TCC-Overlay-Gehäusesitz. Bediener: Handrad. Enden: API 6A, API 6D.

-

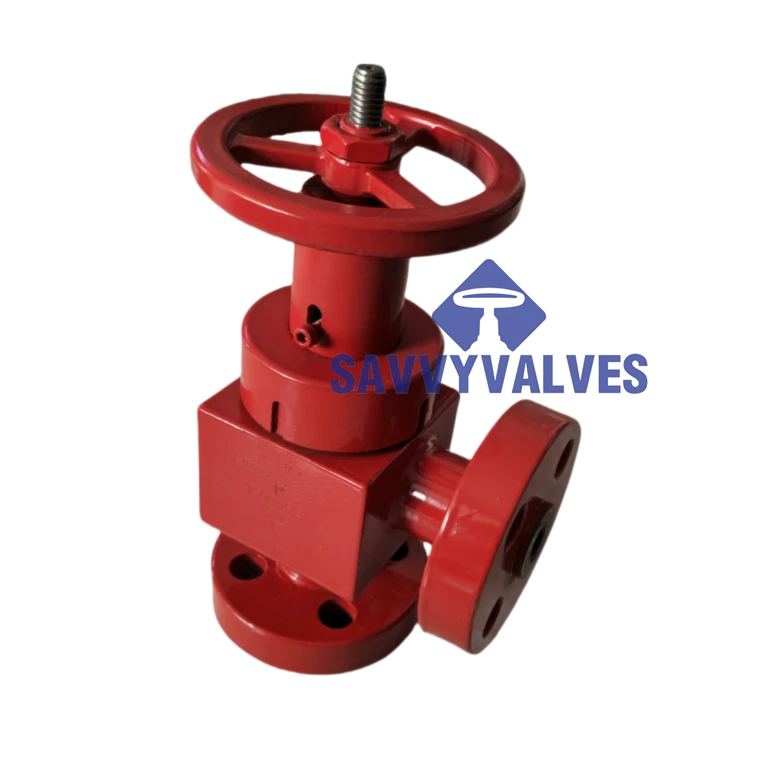

FOTOS ZEIGEN SPEZIFIKATIONEN WIE UNTEN

GRÖSSE: 3″

BEWERTUNG: 10000PSIG

KAROSSERIE UND MOTORHAUBE: TC YG6

STECKER: TC YG20

VORBAU: INCONEL 625

KÄFIG: INCONEL 625

SITZ: YG 6

BETÄTIGUNG: ELEKTRISCHER ANTRIEBSANTRIEB

-

FOTOS ZEIGEN SPEZIFIKATIONEN WIE UNTEN

GRÖSSE: DN100

BEWERTUNG: PN100

KAROSSERIE UND MOTORHAUBE: A216 WCB

STECKER: 410SS

Schaft: 316SS

KÄFIG: 410SS

SITZ: 410SS

BETÄTIGUNG: PNEUMATISCHER ANTRIEBSART

-

Knapp:

Größe: 1/2″

Bewertung: 4500LB

Materialien:

ASTM A105 Gehäuse und Haube

ASTM A105 +Stellite 6 Scheibe

ASTM A182 F6A Schaft

Stellite 6-Overlay-Karosseriesitz

Bedienung: Handrad

Enden: BW gemäß ANSI B16.25

A choke valve is a type of control valve specifically designed to regulate the flow and pressure of fluids—especially in high-pressure systems such as oil and gas production. It works by varying the size of the flow passage through a movable component, often a plug or needle, which reduces or increases flow rate accordingly. Unlike standard valves that primarily open or close flow, choke valves are meant for precise throttling, allowing operators to control production rates and manage pressure drops in wellheads and pipelines. They are built to withstand harsh environments, including corrosive and erosive fluids, thanks to durable materials like tungsten carbide or Inconel. Choke valves can be fixed or adjustable: fixed choke valves use a static orifice size, while adjustable versions allow dynamic control via manual or automated actuation. In many systems, they serve as the first line of control, reducing pressure from reservoir levels to downstream equipment tolerances. Their reliability and accuracy make them essential in high-pressure oilfield operations, ensuring safe, stable, and efficient fluid handling over long periods.