チョークバルブ

-

サイズ: 2インチ

圧力定格:10,000 PSI(API 6Aに準拠)

オペレーター: 電動アクチュエータ

接続端: RTJフランジ (API 6BX)

構成: アングルパターン、バランスのとれたケージトリム

表面仕上げ:サンドブラストおよびエポキシコーティング

温度範囲: -29°C~425°C

-

概要: サイズ:1インチ、定格:10000PSI、10K、材質:ASTM A182 A105本体およびボンネット、ASTM A182 F105+TCCディスク、ASTM A182 F6Aステム、TCCオーバーレイボディシート、オペレーター:ハンドホイール、エンド:API 6A、API 6D。

-

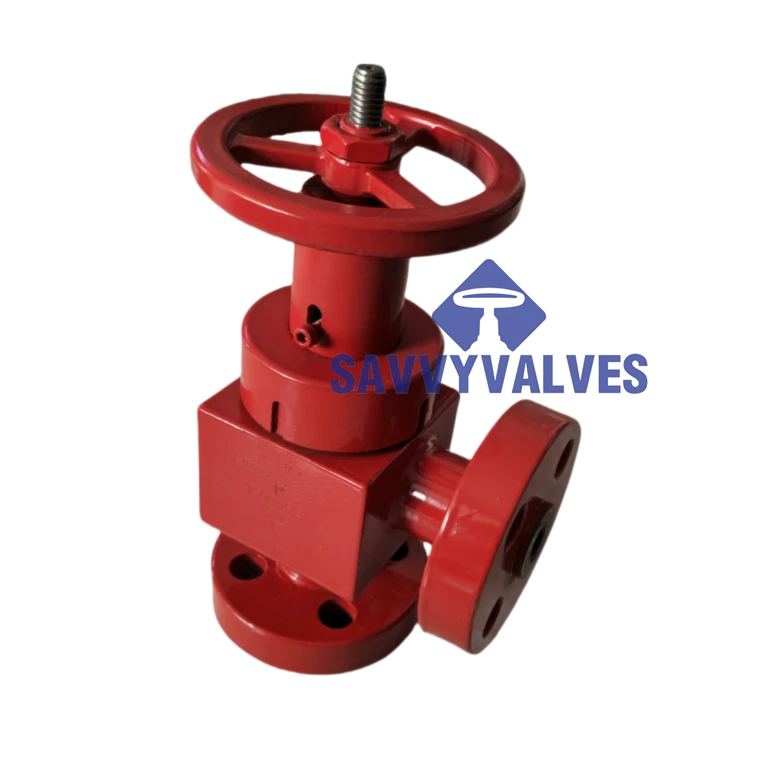

写真の仕様は以下のとおりです

サイズ:3インチ

定格: 10000PSIG

ボディとボンネット:TC YG6

プラグ: TC YG20

ステム:インコネル625

ケージ:インコネル625

座席: YG 6

駆動方式:電動アクチュエータ

-

写真の仕様は以下のとおりです

サイズ:DN100

評価: PN100

ボディとボンネット:A216 WCB

プラグ: 410SS

ステム:316SS

ケージ: 410SS

シート: 410SS

駆動方式:空気圧アクチュエータ

-

簡単な:

サイズ:1/2インチ

評価:4500LB

材料:

ASTM A105ボディとボンネット

ASTM A105 +ステライト6ディスク

ASTM A182 F6Aステム

ステライト6オーバーレイボディシート

オペレーター: ハンドホイール

終了: ANSI B16.25に準拠したBW

A choke valve is a type of control valve specifically designed to regulate the flow and pressure of fluids—especially in high-pressure systems such as oil and gas production. It works by varying the size of the flow passage through a movable component, often a plug or needle, which reduces or increases flow rate accordingly. Unlike standard valves that primarily open or close flow, choke valves are meant for precise throttling, allowing operators to control production rates and manage pressure drops in wellheads and pipelines. They are built to withstand harsh environments, including corrosive and erosive fluids, thanks to durable materials like tungsten carbide or Inconel. Choke valves can be fixed or adjustable: fixed choke valves use a static orifice size, while adjustable versions allow dynamic control via manual or automated actuation. In many systems, they serve as the first line of control, reducing pressure from reservoir levels to downstream equipment tolerances. Their reliability and accuracy make them essential in high-pressure oilfield operations, ensuring safe, stable, and efficient fluid handling over long periods.