Panggangan Anda Memanggang Kayu Panggang Pelet

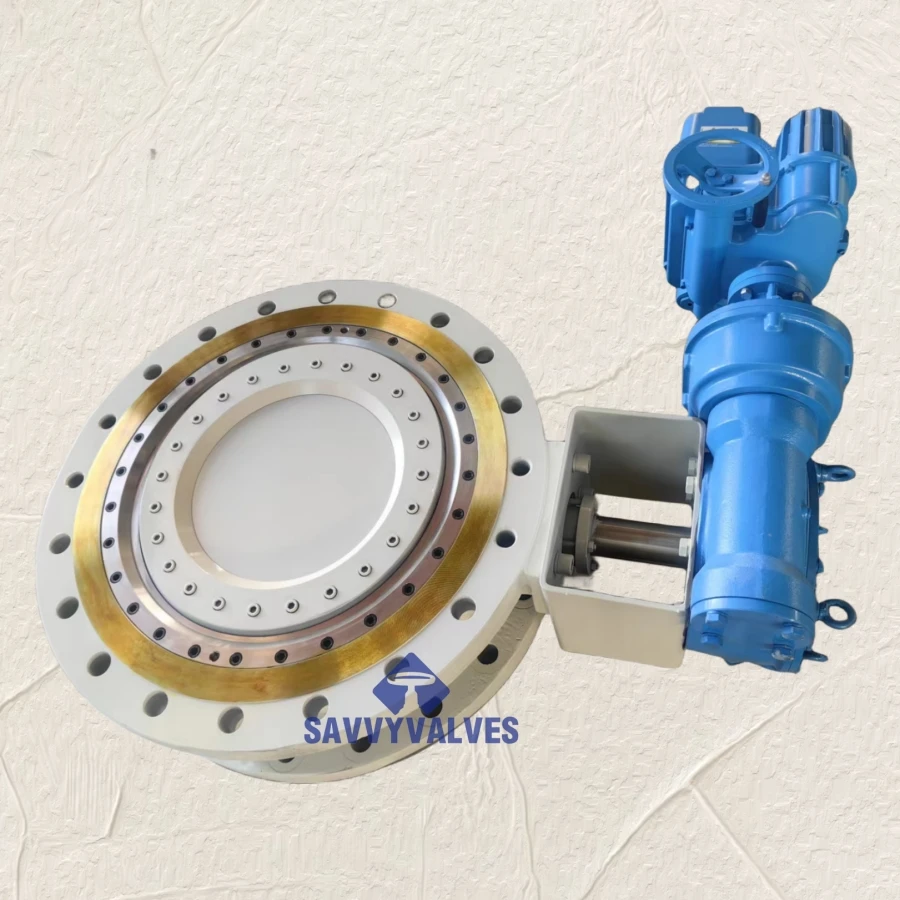

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DIBAWAH INI

UKURAN: 48″

PERINGKAT: 150LB

BODY: ASTM A536 DUCTILE IRON + BODY SEAT 304SS

CAKRAM: BESI DUKTIL ASTM A536

BATANG: SS416

KURSI: EPDM

PENGGERAK: UNIT RODA GIGI

SPESIFIKASI UMUM YANG DIRANCANG

Ukuran: 4″~144″.

Peringkat Tekanan: 150LB, PN6, PN10, PN16, PN20, JIS 5K, JIS 10K, JIS 16K, JIS 20K.

Aplikasi umum: Air. Minyak. Gas.

Desain & Pembuatan: API 609, BS5155, EN593 adalah dasar, ASME B16.34, norma lain dapat digunakan sesuai pesanan.

Dimensi F KE F: API 609, ASME B16.10, BS EN 558, BS 5155

Koneksi: ASME B16.5, EN 1092, BS 4504, ASME B16.47, JIS 5K-20K.

Desain yang aman: batang anti-ledakan.

DAFTAR BAHAN UMUM

BADAN: ASTM A 126, ASTM A 395, ASTM A536 65-45-12, ASTM A351 CF8 CF8M CF3 CF3M, 4A, 5A, C95400, C95800, B62, B148 ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

CAKRAM: ASTM A 126, ASTM A 395, ASTM A536 65-45-12, ASTM A351 CF8 CF8M CF3 CF3M, 4A, 5A, C95400, C95800, B62, B148 ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

KURSI: KURSI BADAN INTEGRAL ATAU BERMUKA KERAS DARI BAJA ANTI KARAT

SEGEL: EPDM, NBR, VITON

OPERATOR: UNIT GIGI

BAHAN KHUSUS LAINNYA TERSEDIA UNTUK DISESUAIKAN.

UJI DAN INSPEKSI

Norma inspeksi dan persetujuan: API598, API6D.

KONTROL KUALITAS

100% Analisis kimia dan uji mekanis dengan bahan baku setiap nomor panas.

Uji DPT 100% dengan coran, sebagian uji MT atau UT, RT selalu tersedia jika diperlukan.

Uji hidrolik 100% dengan cangkang dan segel serta uji udara bertekanan rendah.

JAMINAN

SAVVY VALVES memberikan masa pakai minimal 12 bulan, suku cadang gratis dan petunjuk perawatan akan diberikan bila diperlukan.

The standard double offset butterfly valve rubber seated is designed to provide tight shut-off with reduced seat wear, making it ideal for industrial systems that require reliable flow control and frequent operation. The “double offset” refers to the disc being offset from the valve centerline in two directions, which minimizes contact between the disc and the seat during opening and closing. This design significantly extends the valve's service life and reduces operating torque. The rubber seat ensures bubble-tight sealing, making it suitable for water, air, and non-corrosive fluid applications. Commonly used in water treatment plants, power generation, and district heating systems, this valve offers a good balance of durability, sealing performance, and ease of operation. Its quarter-turn function allows quick shutoff, and the design supports both manual and automated actuation. This valve is especially preferred in systems where low maintenance and high reliability are key requirements.

Jika Anda tertarik dengan produk kami, Anda dapat memilih untuk meninggalkan informasi Anda di sini, dan kami akan segera menghubungi Anda.