グローブバルブ

-

写真は以下の仕様を示しています

サイズ: 1インチ

定格: 800LB

終了:ASME B16.11に準拠したSW

温度: -196 ℃

ボディとボンネット:ASTM A182 F304

ウェッジ:ソリッド ASTM A182 F304+HF

ステム:ASTM A182 F304

シート:HFメタル

作動方式:ハンドホイール

-

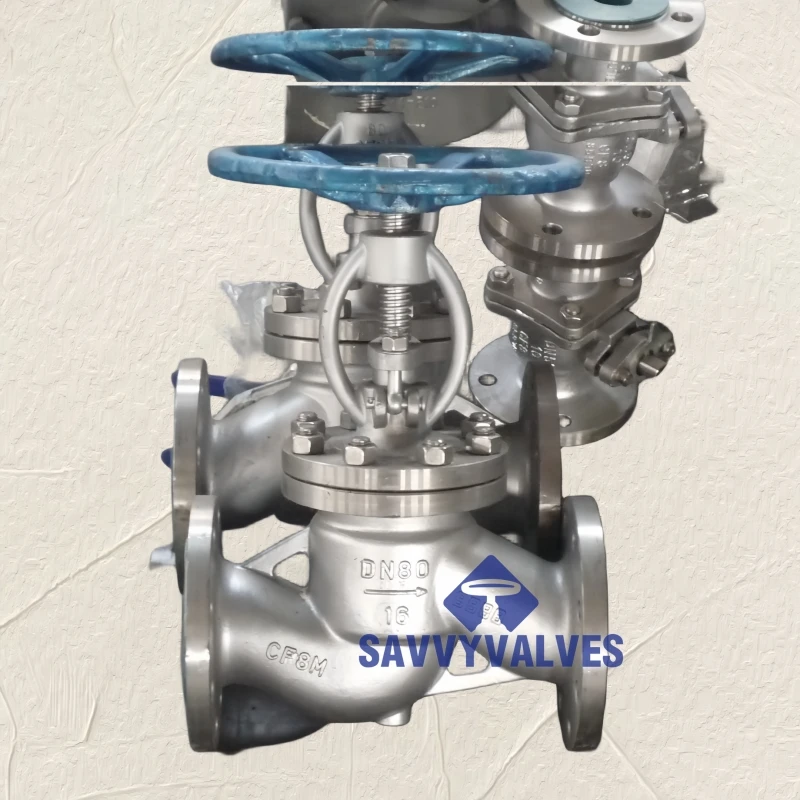

写真は以下の仕様を示しています

サイズ: DN80

評価: PN16

終了:ASME B16.5準拠のRF

温度: -29℃~425℃

ボディとボンネット:ASTM A351 CF8

ディスク:ソリッド ASTM A182 F304+HF

ステム:ASTM A182 F304

シート:HFメタル

作動方式:ハンドホイール

-

Valve Type Y-Pattern Globe Valve

Connection Type Butt Weld Ends (BWE)

Size 2 inch (DN50)

Pressure Class ASME 900LB (Class 900)

Design Standard ASME B16.34

Temperature Range -29°C to +593°C -

サイズ: DN50

圧力定格:PN25

主な材質:本体、ボンネット、ディスク、ステム、シート:ASTM B148 C95800(ニッケルアルミニウム青銅)

操作: 手動(ハンドホイール操作)

接続端: RF (凸面)

構成: アングルパターン、スクリューダウン逆止(SDNR)ディスク

表面仕上げ:サンドブラスト

動作温度範囲: -29°C~425°C

-

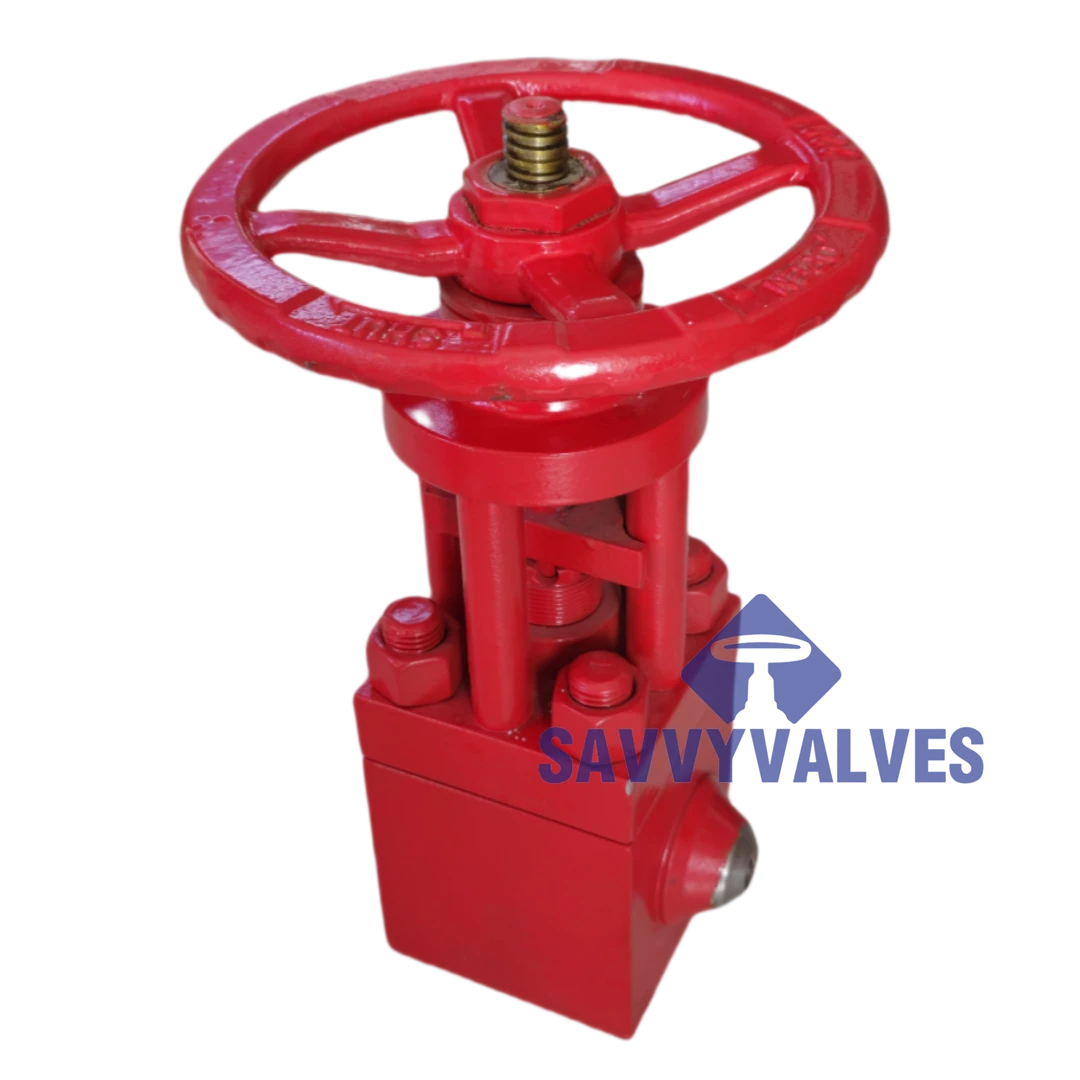

簡単な:

サイズ:1/2インチ

評価:4500LB

材料:

ASTM A105ボディとボンネット

ASTM A105 +ステライト6ディスク

ASTM A182 F6Aステム

ステライト6オーバーレイボディシート

オペレーター: ハンドホイール

終了: ANSI B16.25に準拠したBW

-

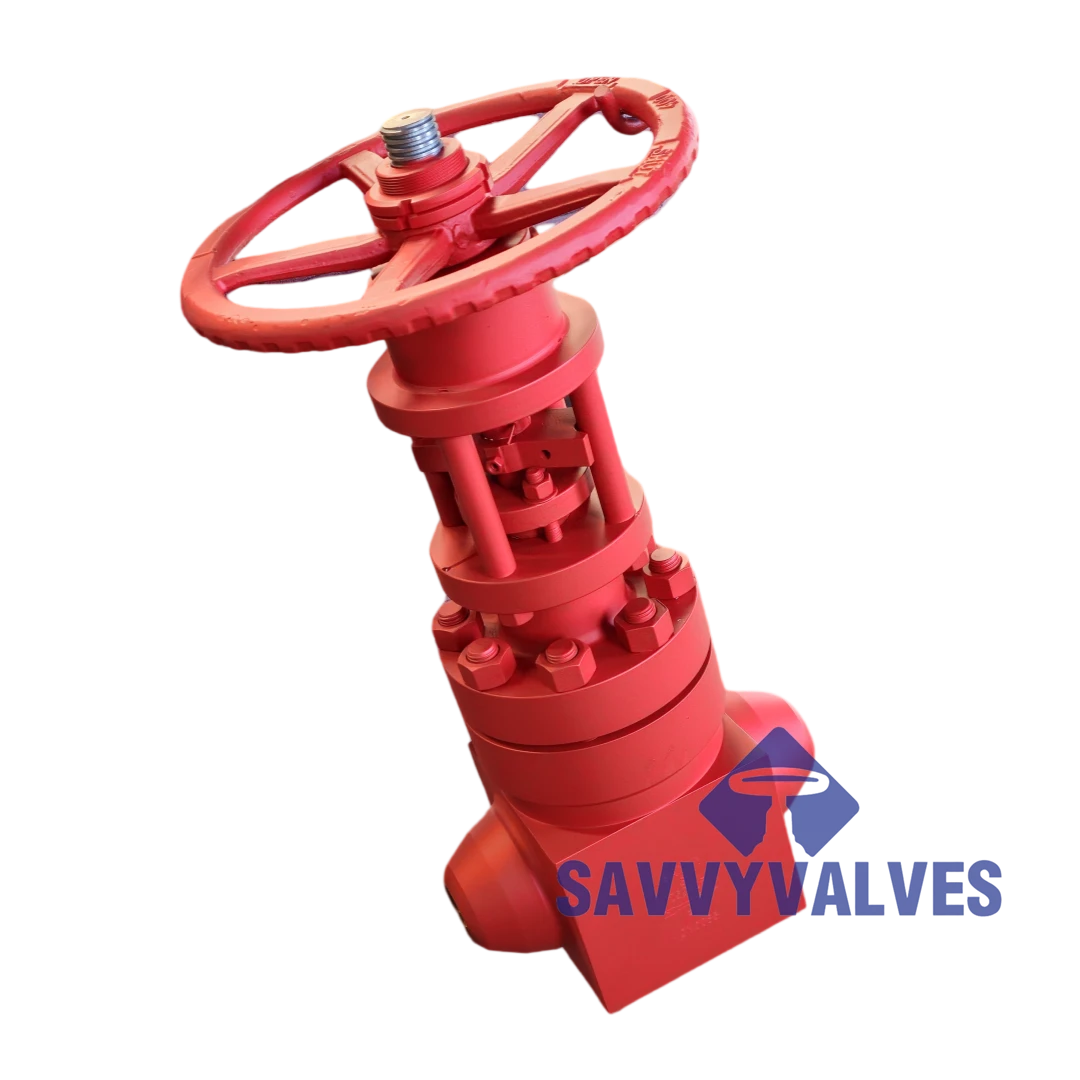

簡単な:

サイズ:3インチ

評価:2500LB

材料:

ASTM A182 F11 ボディとボンネット

ASTM A182 F11+ステライト6ディスク

ASTM A182 F6Aステム

ステライト6オーバーレイボディシート

オペレーター: ハンドホイール

終了: ANSI B16.25に準拠したBW

-

写真の仕様は以下のとおりです

サイズ:DN15

評価:PN16

ボディとボンネット:真鍮

ディスク:ブラス

ステム:真鍮

シート:真鍮

駆動方式:ホイール

A globe valve is a linear motion valve primarily used to start, stop, and regulate fluid flow in a pipeline. Its internal structure includes a movable disk-type element and a stationary ring seat in a generally spherical body—hence the name "globe" valve. When the actuator or handwheel is turned, the stem moves the plug up or down, altering the flow path and providing throttling control. This design offers a good shutoff capability and is well-suited for applications where precise flow regulation is required. Due to the tortuous flow path, globe valves tend to have higher pressure drops than other types, but they compensate with excellent control accuracy. They are often used in chemical processing, power generation, and oil and gas systems where controlled flow and tight sealing are essential. Globe valves can handle various fluids including steam, water, oil, and gas, and are available in manual, pneumatic, or electric actuation versions. Their versatility and dependable operation make them a top choice for systems requiring modulation or frequent operation.

- 1

- 2