Katup Globe

-

Singkat:

Ukuran: 1/2″

Peringkat: 4500LB

Bahan:

Bodi dan kap ASTM A105

ASTM A105 +stellite 6 Cakram

Batang ASTM A182 F6A

Jok bodi berlapis Stellite 6

Operator: roda tangan

Ujung: BW sesuai ANSI B16.25

-

Ukuran: DN50

Peringkat Tekanan: PN25

Bahan Utama: Bodi, Kap Mesin, Cakram, Stem, Jok: ASTM B148 C95800 (Perunggu Nikel-Aluminium)

Operator: Manual (Dioperasikan dengan Roda Tangan)

Ujung Sambungan: RF (Wajah Terangkat)

Konfigurasi: Pola Sudut, Cakram Non-Return Sekrup Bawah (SDNR)

Permukaan akhir: Sandblasted

Kisaran Suhu Operasional: -29°C hingga 425°C

-

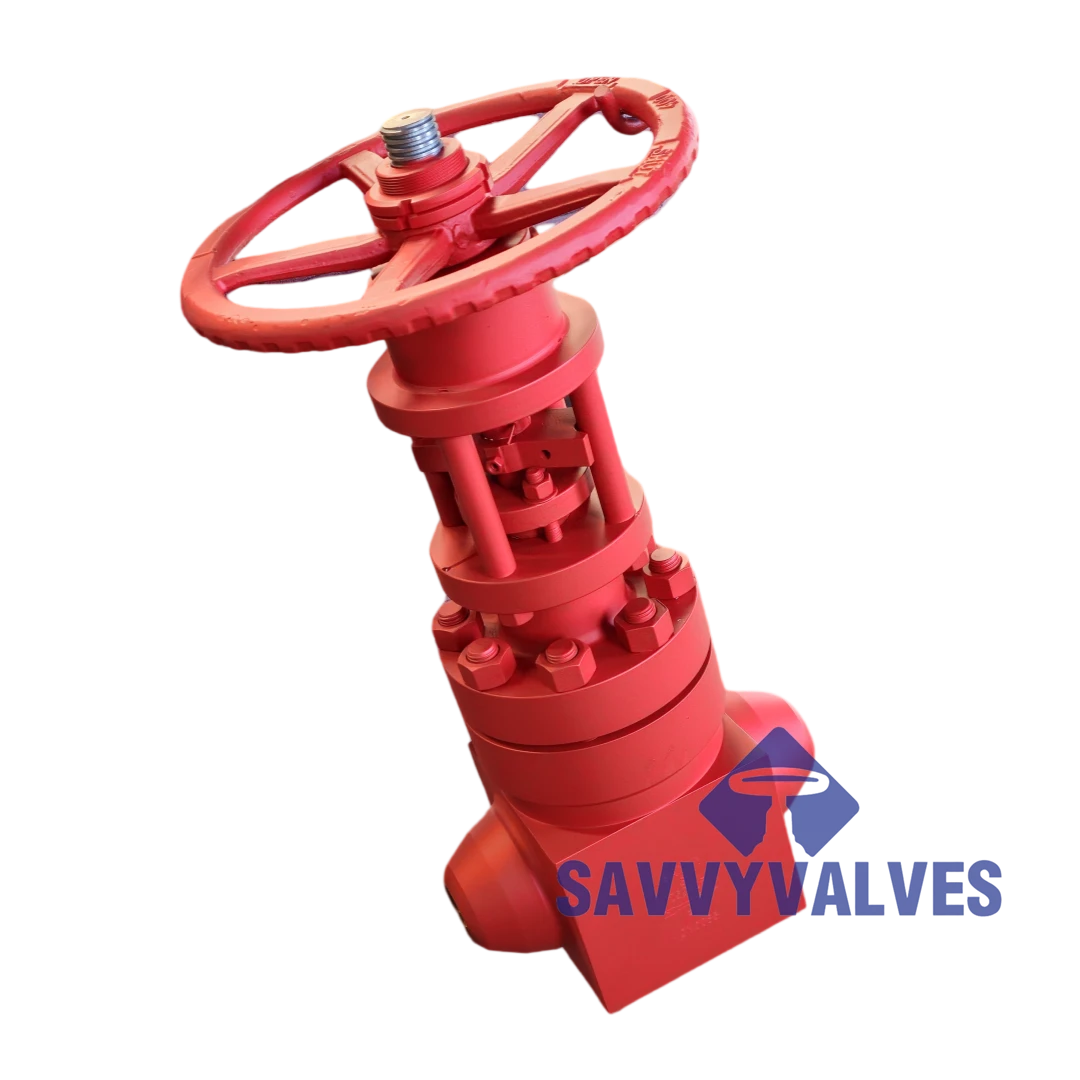

Singkat:

Ukuran: 3″

Peringkat: 2500LB

Bahan:

Bodi dan kap ASTM A182 F11

ASTM A182 F11+stellite 6 Cakram

Batang ASTM A182 F6A

Jok bodi berlapis Stellite 6

Operator: roda tangan

Ujung: BW sesuai ANSI B16.25

-

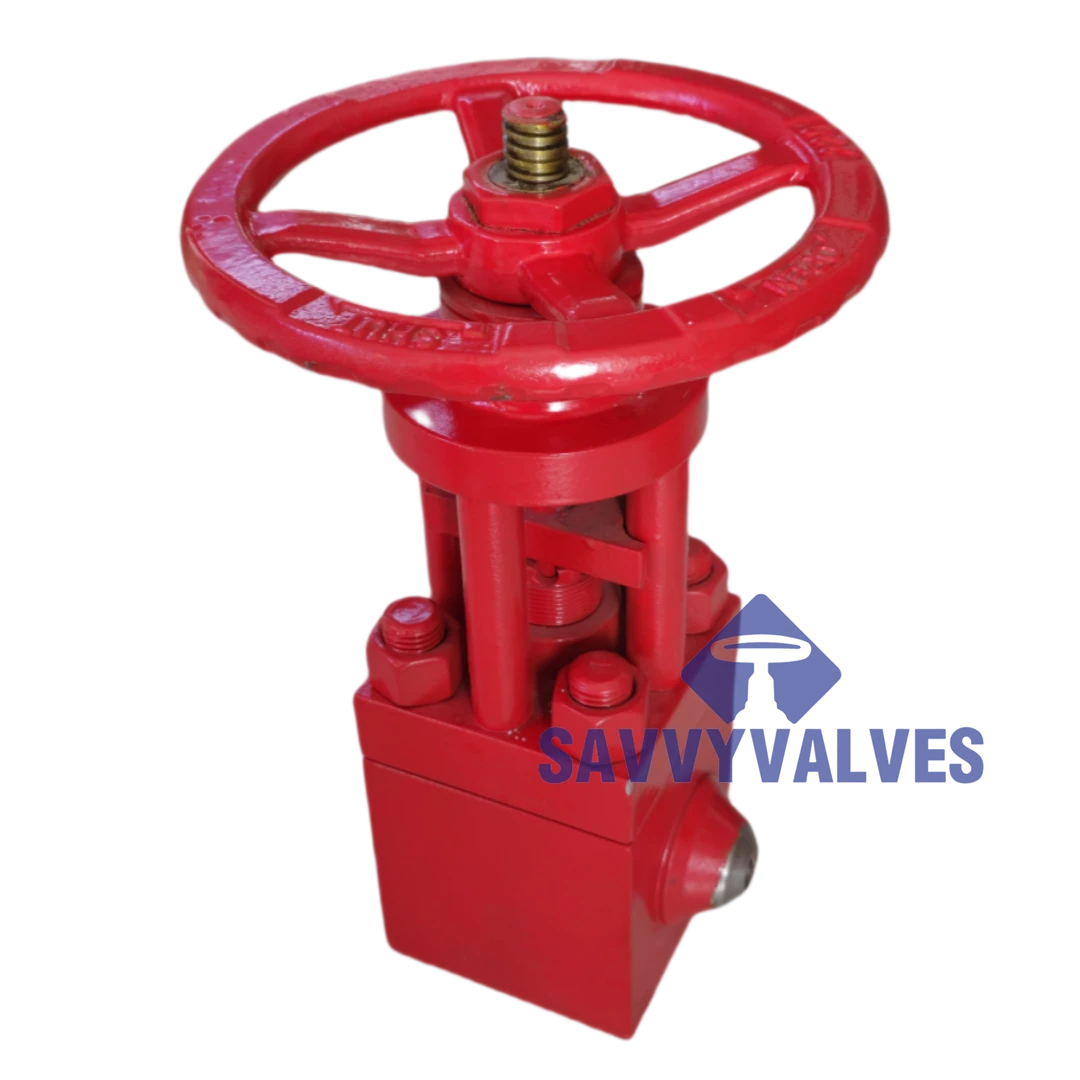

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI

UKURAN:DN15

PERINGKAT:PN16

BODY DAN KAP MESIN : KUNINGAN

CAKRAM : KUNINGAN

BATANG: KUNINGAN

KURSI: KUNINGAN

PENGGERAK: RODA

A globe valve is a linear motion valve primarily used to start, stop, and regulate fluid flow in a pipeline. Its internal structure includes a movable disk-type element and a stationary ring seat in a generally spherical body—hence the name "globe" valve. When the actuator or handwheel is turned, the stem moves the plug up or down, altering the flow path and providing throttling control. This design offers a good shutoff capability and is well-suited for applications where precise flow regulation is required. Due to the tortuous flow path, globe valves tend to have higher pressure drops than other types, but they compensate with excellent control accuracy. They are often used in chemical processing, power generation, and oil and gas systems where controlled flow and tight sealing are essential. Globe valves can handle various fluids including steam, water, oil, and gas, and are available in manual, pneumatic, or electric actuation versions. Their versatility and dependable operation make them a top choice for systems requiring modulation or frequent operation.

- 1

- 2