In the intricate world of industrial flow control, the knife gate valve stands out as a robust and reliable solution for managing challenging media such as slurries, powders, and viscous fluids. Our cutting-edge range of knife gate valves is engineered to deliver unparalleled performance, ensuring smooth operations, reduced downtime, and enhanced safety across various industries. From the precision of an automatic knife gate valve to the resilience of a high temperature knife gate valve, and at a competitive cena zasuwy nożowej, we have the perfect solution to meet your specific industrial demands. Explore how our valves can revolutionize your process control.

Automatic Knife Gate Valve: Precision and Control at Your Fingertips

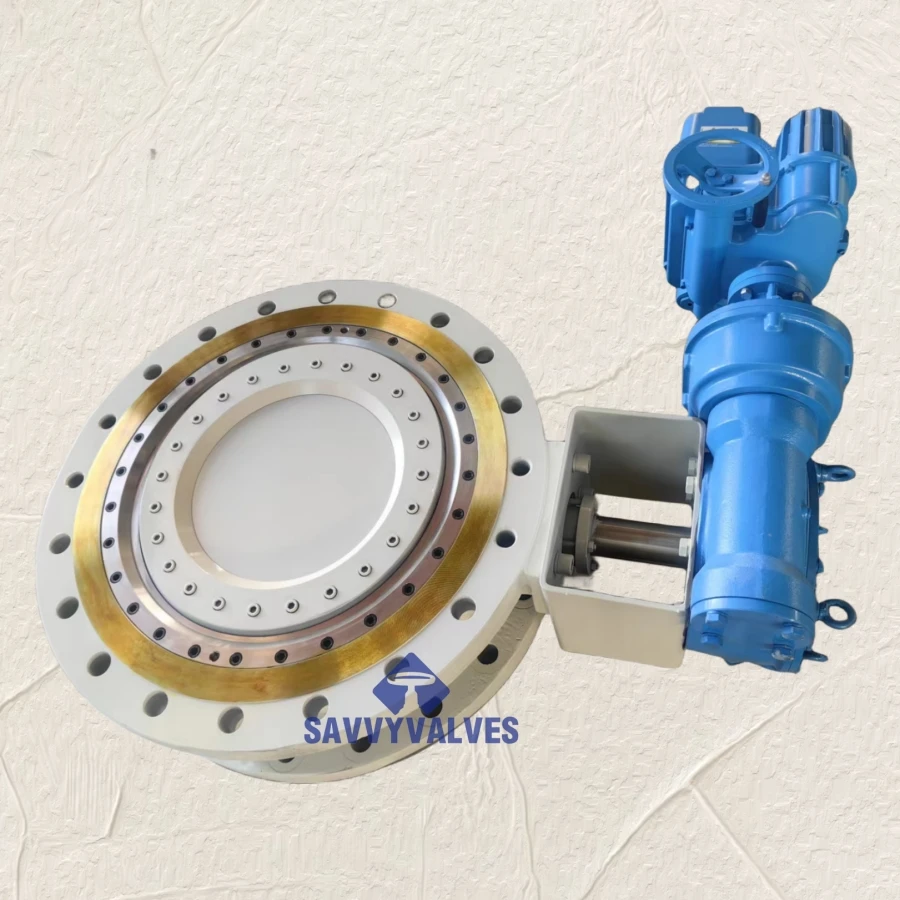

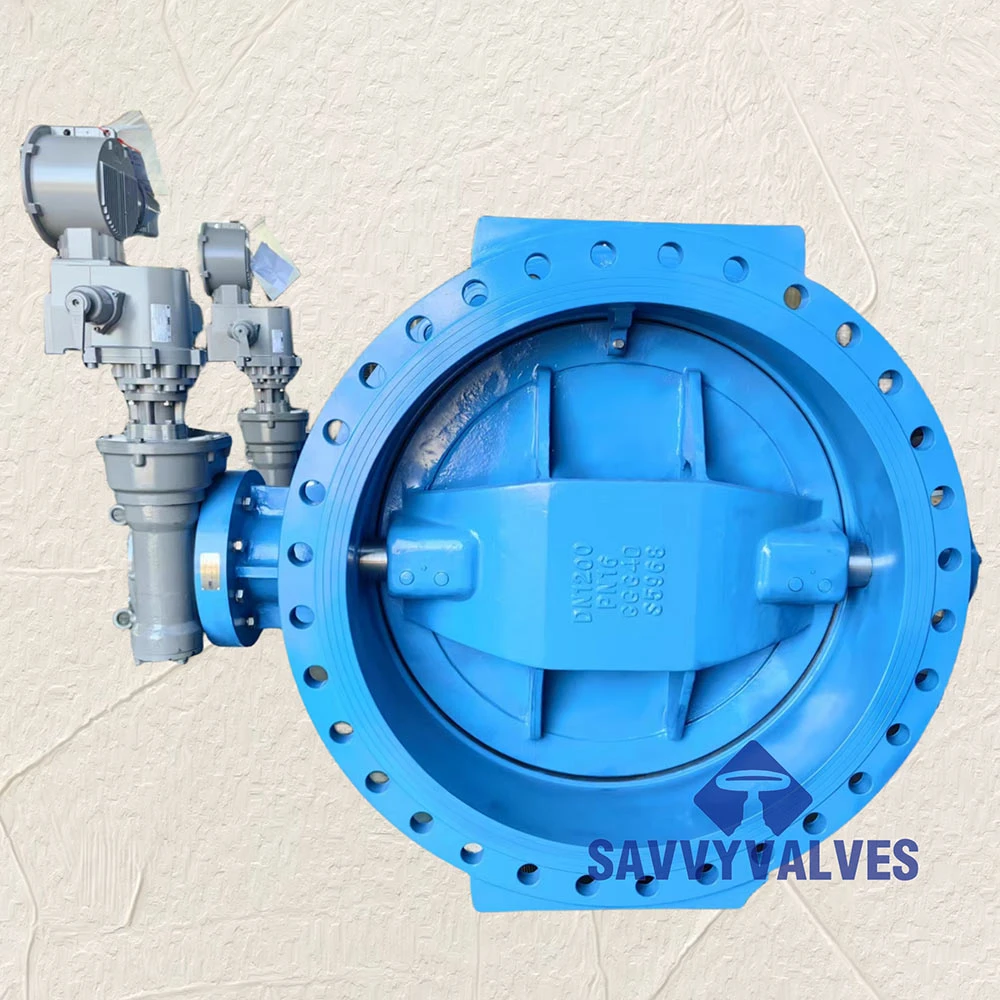

Embrace the future of flow management with our advanced automatic knife gate valve solutions. Designed for seamless integration into modern automated systems, these valves offer precise control and rapid response, significantly enhancing operational efficiency and safety. Whether actuated pneumatically, electrically, or hydraulically, our automatic knife gate valves provide reliable remote operation, reducing the need for manual intervention and minimizing human error.

The inherent design of the automatic knife gate valve allows for swift opening and closing, making it ideal for applications requiring quick shut-off or frequent cycling. This automation capability is particularly beneficial in industries like wastewater treatment, mining, and pulp and paper, where consistent and precise control of abrasive or high-solids media is critical. By automating your valve operations, you not only boost productivity but also ensure consistent process parameters, leading to higher quality outputs and lower operating costs.

High Temperature Knife Gate Valve: Built to Withstand Extreme Heat

For demanding applications where extreme temperatures are a constant challenge, our high temperature knife gate valve offers an indispensable solution. Engineered with specialized materials and construction techniques, these valves are designed to maintain their integrity and sealing capabilities in environments reaching exceptionally high temperatures. Industries such as power generation, steel manufacturing, and specialized chemical processing often encounter conditions that would compromise standard valves, but our high temperature models are built to perform reliably under such duress.

Each high temperature knife gate valve incorporates advanced packing and seating materials that resist thermal degradation, ensuring a tight seal even when exposed to intense heat. The robust body construction is designed to prevent thermal expansion and contraction issues that can lead to leakage or valve failure. Investing in a high temperature knife gate valve means securing uninterrupted operations in critical high-heat processes, ultimately contributing to enhanced safety, reduced maintenance, and prolonged equipment lifespan.

Knife Gate Valve Price: Delivering Unmatched Value and Performance

When it comes to the cena zasuwy nożowej, we believe in offering solutions that provide exceptional value without compromising on quality or performance. Our extensive range of knife gate valves is priced competitively, reflecting the superior engineering, durable materials, and long-term reliability they offer. We provide options that cater to various budgetary considerations, from cost-effective standard models to highly specialized automatic and high-temperature variants, ensuring that you can find the perfect valve to match your technical requirements and financial planning.

The overall cena zasuwy nożowej is influenced by factors such as size, material of construction (e.g., stainless steel, ductile iron), actuation type (manual, automatic), and specific certifications. We offer transparent pricing structures and are often able to provide attractive discounts for bulk purchases or long-term partnerships. Choosing our knife gate valves is an investment in durable, efficient, and low-maintenance flow control, ultimately translating into significant savings in operational expenditures over the valve's extended service life.

Why Our Knife Gate Valves Stand Out: Durability, Versatility, and Innovation

Our comprehensive selection of knife gate valves is designed with the end-user in mind, focusing on durability, versatility, and innovative features. Whether you need a simple manual valve or a sophisticated automatic knife gate valve, each product is manufactured to the highest industry standards, ensuring reliable performance in the most challenging industrial environments. The inherent design, with its sharp blade, excels at cutting through and sealing off media that often cause issues for other valve types, such as thick slurries, fibrous materials, and dry bulk solids.

Furthermore, our commitment to continuous improvement means we integrate the latest technologies and materials into our valves, offering superior sealing capabilities, reduced fugitive emissions, and extended service life. The adaptability of our knife gate valves across a wide spectrum of applications, from mining and wastewater to pulp and paper and power generation, underscores their indispensable role in modern industrial processes. When you choose our knife gate valves, you are selecting a solution that combines proven reliability with cutting-edge innovation.

Knife Gate Valves FAQs

-

What are the primary benefits of an automatic knife gate valve?

An automatic knife gate valve offers several key benefits, primarily enhanced operational efficiency, precision control, and improved safety. Automation eliminates the need for manual intervention, allowing for remote operation and quick response times, which is crucial in emergency shut-off situations or high-frequency cycling applications. This leads to consistent process parameters, reduced labor costs, and a significant decrease in potential human error. They are ideal for integration into Supervisory Control and Data Acquisition (SCADA) systems.

-

In what specific industries is a high temperature knife gate valve essential?

A high temperature knife gate valve is essential in industries where fluid or material temperatures consistently exceed the capabilities of standard valves. This includes sectors such as power generation (e.g., steam lines, ash handling), steel manufacturing (e.g., blast furnace gases, slag handling), and certain chemical processing plants where extreme exothermic reactions or high-temperature media are involved. These valves are designed with specialized materials and sealing components to withstand thermal stress and maintain integrity under intense heat, ensuring reliable and safe operation.

-

What factors influence the knife gate valve price?

The cena zasuwy nożowej is influenced by several factors. These include the valve's size (larger valves generally cost more), the material of construction (e.g., stainless steel is typically more expensive than ductile iron), the pressure rating, and the type of actuation (manual is usually the least expensive, followed by pneumatic, and then electric). Additional features like specialized coatings for abrasion resistance, different packing materials, or certifications can also impact the final price. Custom designs for unique applications will also affect the cost.

-

Can knife gate valves handle abrasive media effectively?

Yes, knife gate valves are exceptionally well-suited for handling abrasive media. Their design, featuring a thin, sharp blade, allows them to cut through slurries, gritty fluids, and dry bulk solids with minimal accumulation and wear. Unlike other valve types where abrasive particles can get trapped and damage sealing surfaces, the knife gate's shearing action helps prevent this. Many knife gate valves are also available with specialized hardened seats or coatings to further enhance their resistance to abrasive wear, prolonging their service life in challenging applications.

-

How do I determine if an automatic or manual knife gate valve is right for my application?

The choice between an automatic knife gate valve and a manual one depends on your application's specific requirements. A manual valve is suitable for applications where infrequent operation is acceptable, cost is a primary concern, and immediate remote control isn't necessary. An automatic valve is ideal for applications requiring frequent cycling, remote operation, integration into automated control systems, or situations where rapid response and consistent, precise control are crucial for process efficiency and safety. Consider factors like operating frequency, personnel safety, existing automation infrastructure, and budget when making your decision.