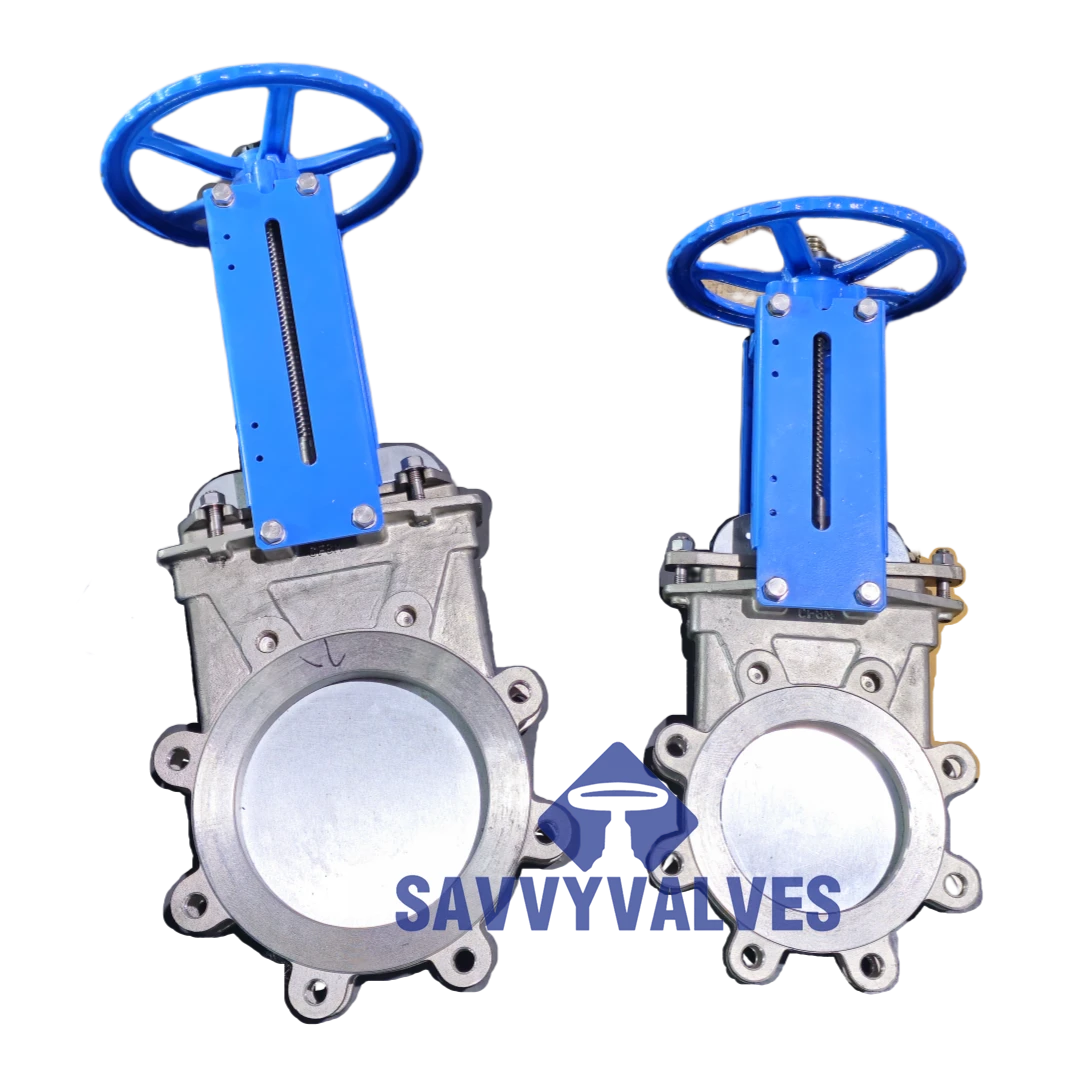

Zawory nożowe

-

Krótki:

Rozmiar: 6″, 8″

Ocena:150LB

Przybory:

Nadwozie ASTM A351 CF8M

Bramka nożowa ASTM A182 F316+HCR

Mostek i jarzmo CS

Siedzisko PTFE

Operator: pokrętło ręczne

-

Rozmiar i ciśnienie: Średnica nominalna: 14" (DN 350)

Nominalne ciśnienie: JIS 5K (7 kgf/cm² @ 120°C)

Materiał korpusu: stal węglowa ASTM A216 WCB

-

Rozmiar i ciśnienie • Średnica nominalna: 14" (DN 350)

Nominalne ciśnienie: JIS 5K (7 kgf/cm² @ 120°C)

Materiał korpusu: stal węglowa ASTM A216 WCB

-

• Rozmiar: 8 cali

• Nominalne ciśnienie: 150 funtów

• Materiał korpusu: CF8M (odpowiednik odlewu ze stali nierdzewnej 316)

• Kluczowe materiały składowe:

o Tarcza bramowa: stal nierdzewna 316 + HCR (powierzchnia chromowana na twardo lub utwardzana)

o Trzonek: stal nierdzewna 316

o Siedzisko: PTFE (politetrafluoroetylen)

• Obsługa: Obsługa za pomocą pokrętła

• Połączenie końcowe: pełne z kołnierzem

• Kierunek przepływu: jednokierunkowy

A knife gate valve is a specialized type of gate valve designed to handle thick fluids, slurries, and materials with suspended solids. It features a sharp-edged blade or "knife" that can cut through dense media to open or close the flow path. When the valve is operated, the gate moves vertically down into the flow path to stop flow, or up to allow full passage. This valve is particularly effective in industries like wastewater treatment, pulp and paper, mining, and chemical processing, where traditional valves may clog or struggle with semi-solid materials. Unlike standard gate valves, knife gate valves provide a tight seal even in abrasive or sticky applications. They are generally used in low-pressure, low-velocity systems and are available in manual, pneumatic, or electric actuation options. Their compact design and minimal flow resistance make them easy to maintain and ideal for space-constrained installations. The knife gate valve's ability to cleanly shear through thick media without leakage or blockages makes it a critical component in many heavy-duty and industrial systems.