Vlinderkleppen

-

FOTO TOONT SPECIFICATIES ZOALS HIERONDER

MAAT: 8″~14″

BEOORDELING: 200WOG

BODY: ASTM A216 WCB

SCHIJF: ASTM A351 CF8

STEEL: SS416 PINLOOS

STOEL: NBR

AANDRIJVING: TANDWIELEENHEID

-

MAAT: DN700

BEOORDELING: PN6

CARROSSERIE: ASTM A536 65-45-12

SCHIJF: ASTM A351 CF8M

STEEL: SS416 PINLOOS

STOEL: NBR

SCHILDERIJ: FLUORKOOLSTOF, C5-I

AANDRIJVING: TANDWIELEENHEID

-

Maat: 4″

Beoordeling: 150LB

Einden: Gelast volgens ANSI B16.5

Materialen:

ASTM A216 WCB-behuizing

ASTM A182 F316L-afwerkingen

Operator: ISO5211 montagepad voor actuator

-

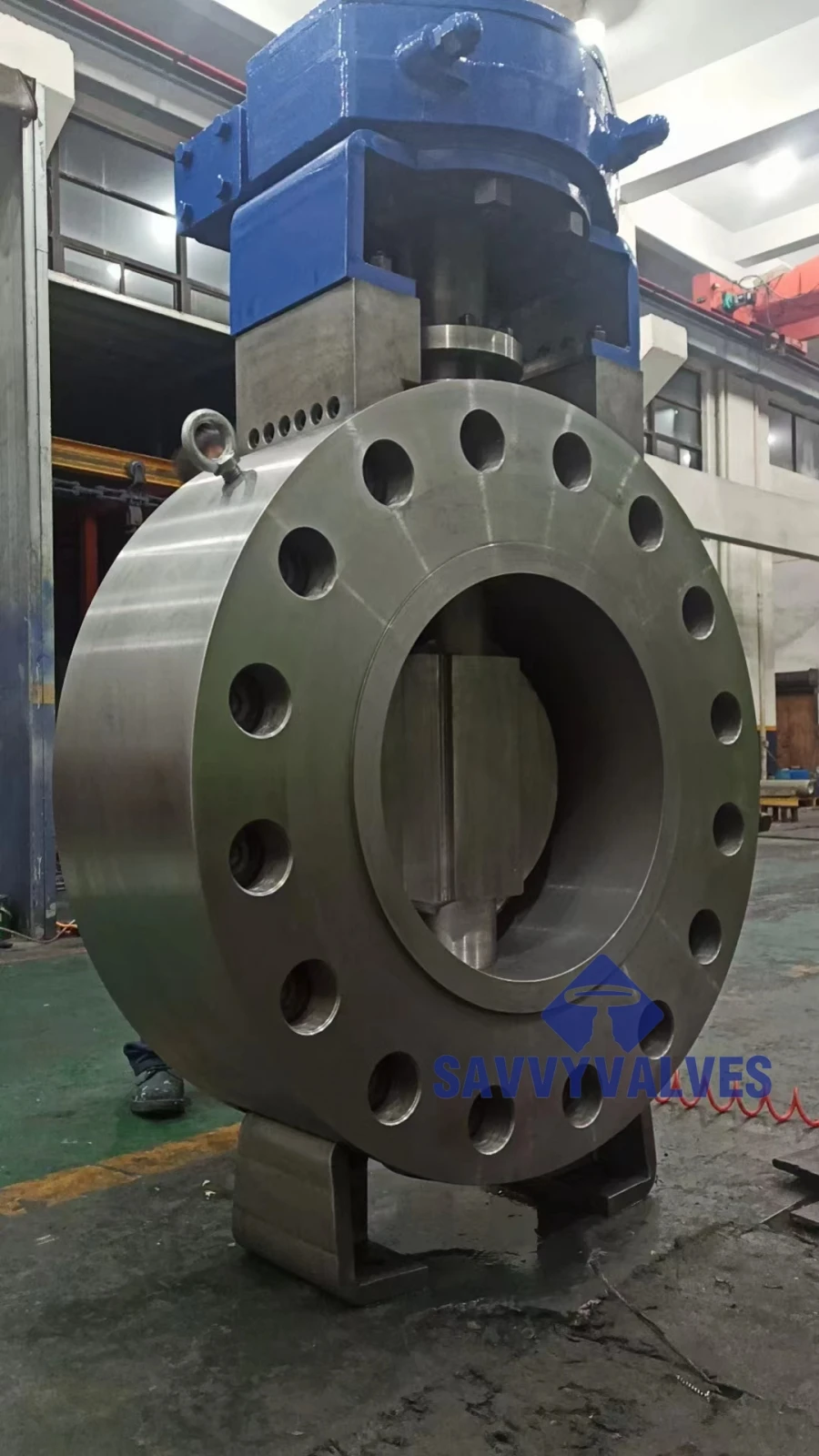

FOTO'S TONEN SPECIFICATIES ZOALS HIERONDER

MAAT: DN450

BEOORDELING: PN16

LICHAAM: ASTM 536 NORMAAL IJZER 65-45-12

SCHIJF: ASTM A536 NOMINAAL IJZER 65-45-12+ENP

STEEL: SS416 PINLOOS

ZITTING: EPDM

AANDRIJVING: TANDWIELEENHEID

-

VOORBEELDSPECIFICATIES

MAAT: 26″

BEOORDELING: 1500LB

LICHAAM: ASTM A105N

SCHIJF: ASTM A182 F316

VERLENGD JUK: ASTM A182 F5

STEM: SS416

ZETEL: ASTM A182 F316

SEAL: SS316+GRAPHITE LAMINATED

AANDRIJVING: TANDWIELEENHEID

-

MAAT: 8″~14″

BEOORDELING: 200WOG

LICHAAM: ASTM A536 NORMAAL IJZER

SCHIJF: ASTM A536 NOMINAAL IJZER

STEEL: SS416 PINLOOS

STOEL: NBR

AANDRIJVING: TANDWIELEENHEID

-

Maat: 6" (DN150)

Drukclassificatie: 150 lb (ASME B16.5)

Belangrijkste materialen:

Lichaam: ASTM A395 (nodulair gietijzer)

Schijf: ASTM A351 CF8M (roestvrij staal 316) met PTFE-coating

Steel: AISI 316 roestvrij staal

Zitting: versterkt PTFE (polytetrafluorethyleen)

Bediening: hendelbediend

Eindverbinding: geschroefde nokken (conform ASME B16.5)

-

FOTO TOONT SPECIFICATIES ZOALS HIERONDER

MAAT: 2,5″

BEOORDELING: 125LB

LICHAAM: ASTM A536 NORMAAL IJZER

SCHIJF: ASTM A536 NOMINAAL IJZER 65-45-12

STEEL: SS416 PINLOOS

ZITTING: EPDM

AANDRIJVING: HENDEL

-

Maat: 4” & 6” (DN100 & DN150)

Drukclassificatie: 150 lb (PN16)

Belangrijkste materialen:

Carrosserie en schijf: CPVC (corrosiebestendig, lichtgewicht ontwerp)

Steel: roestvrij staal 304 (hoge sterkte, uitstekende corrosiebestendigheid)

Zitting: EPDM (Superieure afdichting, chemisch bestendig)

Bediening: Hendel (Snelle en eenvoudige handmatige bediening)

Verbindingstypen:

Wafertype – Compact ontwerp voor standaard flensinstallatie

Lug-type – Maakt verwijdering aan één kant mogelijk voor eenvoudig onderhoud

Monoflange – Flexibele aanpassing aan meerdere flensnormen

A butterfly valve is a type of quarter-turn valve used to regulate, isolate, or start and stop fluid flow in a piping system. It consists of a circular disc or plate mounted on a rotating shaft. When the handle or actuator turns the shaft 90 degrees, the disc moves from a fully closed to a fully open position, allowing flow through the valve. The disc remains in the flow path even when open, which means there is always a slight pressure drop. Butterfly valves are known for their compact design, fast operation, and cost-effectiveness, especially in large-diameter pipelines. They come in various types, such as wafer, lug, and double or triple offset styles, depending on the pressure and sealing requirements. These valves are widely used in industries such as water treatment, HVAC, chemical processing, oil and gas, and food and beverage, due to their reliability, low maintenance, and easy installation.

- 1

- 2