Katup Bola

-

Gambar menunjukkan katup bola yang dipasang pada trunnion API 608, lubang yang diperkecil, 2 bagian

UKURAN: 10″*8″

PENILAIAN: 150 LB

BODI DAN KAP MESIN : ASTM A216 WCB

BOLA: ASTM A182 F316

BATANG: ASTM A182 F316

KURSI: KERAH ASTM A182 F316 DENGAN SISIPAN DEVLON

MUSIM SEMI: INCONEL X-750

PENGGERAK: UNIT RODA GIGI

-

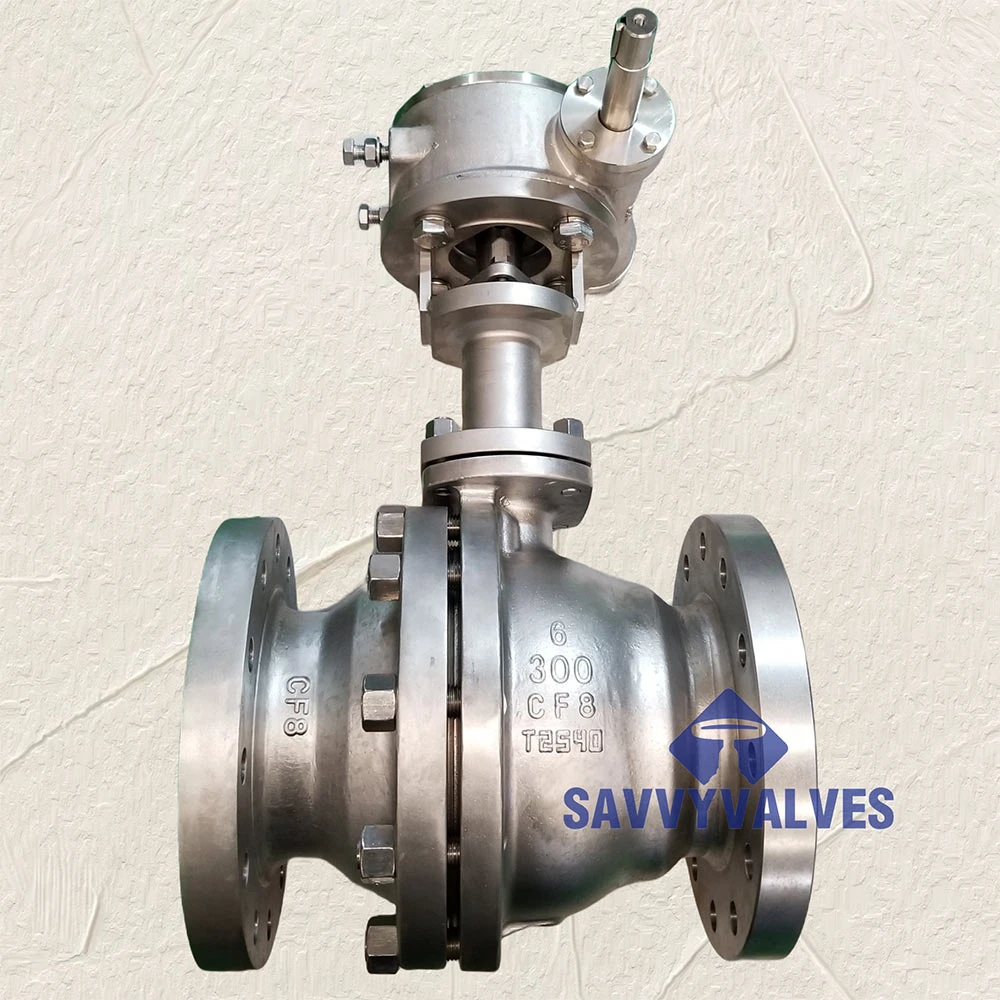

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI

UKURAN: 6″

PERINGKAT: 300LB

AKHIR: BERFLANG SESUAI DENGAN ASME B16.5 300LB

SUHU: -70 ℃

BODI DAN KAP MESIN : ASTM A351 CF8

BOLA: ASTM A182 F304

BATANG: ASTM A182 F304

KURSI: PCTFE BERTENAGA PEGAS

AKTUASI: AKTUATOR PNEUMATIK

-

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI:

UKURAN: 6″

PERINGKAT: 300LB

AKHIR: FLANGE SESUAI DENGAN ASME B16.5

SUHU: -196 ℃

BODI DAN KAP MESIN : ASTM A182 F304

BOLA: ASTM A182 F304+HF

KURSI: PCTFE ATAU LOGAM HF

AKTUASI: MANUAL DAN GIR

-

Ukuran: 15A, 25A

Peringkat Tekanan: JIS 5K

Bahan Utama:

Bodi/Kap Mesin: ASTM B62 C83600 (Perunggu Cor)

Bola : Monel K500

Batang: Monel K500

Dudukan: RPTFE (PTFE yang diperkuat)

Operator: Tuas Manual

Ujung Sambungan: JIS B2220 5K Flanged Face (FF)

Permukaan akhir: Sandblasted & Degreased

Kisaran suhu: -29°C hingga 120°C

-

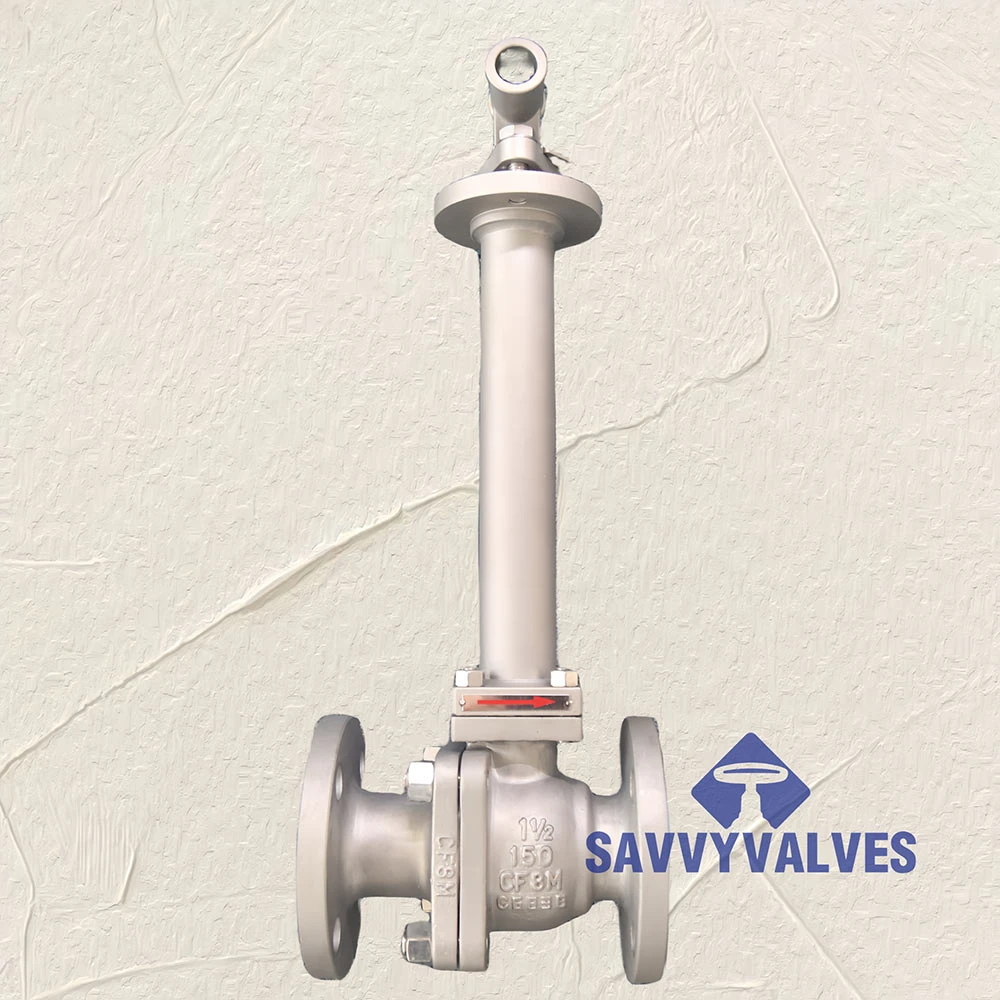

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI

UKURAN: 1-1/2″

PERINGKAT: 150LB

AKHIR: BERFLANG SESUAI DENGAN ASME B16.5 300LB

SUHU: -196 ℃

BODI DAN KAP MESIN : ASTM A351 CF8M

BOLA: ASTM A182 F316+HCR

BATANG: ASTM A182 F316

KURSI: PCTFE BERTENAGA PEGAS

PENGGERAK: TUAS

-

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI:

UKURAN: 1″

PERINGKAT: 150LB

AKHIR: BW SESUAI ASME B16.25

SUHU: -196 ℃

BODI DAN KAP MESIN : A182 F316

BOLA: ASTM A182 F316+HF

BATANG: ASTM A182 F316

KURSI: PEEK ATAU HF METAL

AKTUASI: MANUAL DAN GIR

-

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI:

UKURAN: 8″

PERINGKAT: 150LB

AKHIR: FLANGE SESUAI DENGAN ASME B16.5

SUHU: -196 ℃

BODI DAN KAP MESIN : A351 CF8M

BOLA: ASTM A182 F316+HF

BATANG: ASTM A182 F316

KURSI: PCTFE ATAU LOGAM HF

AKTUASI: MANUAL DAN GIR

-

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI:

UKURAN: 3/4″ 6″

PERINGKAT: 150LB 300LB

AKHIR: FLANGE SESUAI DENGAN ASME B16.5

SUHU: -196 ℃

BODI DAN KAP MESIN : ASTM A182 F304

BOLA: ASTM A182 F304+HF

KURSI: PCTFE ATAU LOGAM HF

AKTUASI: MANUAL DAN GIR

-

SPESIFIKASI SAMPEL

UKURAN: 2″

PENILAIAN: 600LB

BODI DAN KAP MESIN : B62

BOLA: ASTM A182 F316

BATANG: ASTM A182 F316

KURSI: PTFE

PENGGERAK: RODA

-

FOTO MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH INI

UKURAN:DN25

PERINGKAT:PN16

BODY DAN KAP MESIN : KUNINGAN

CAKRAM : KUNINGAN

BATANG: KUNINGAN

KURSI: KUNINGAN

PENGGERAK: TUAS

A ball valve is a type of quarter-turn valve that controls flow using a hollow, perforated, and pivoting ball inside the valve body. When the ball’s hole is aligned with the pipeline, fluid flows freely; when rotated 90 degrees, the flow is completely blocked. This simple mechanism makes ball valves highly reliable for shutoff and control applications. Ball valves are known for their tight sealing performance, durability, and ease of operation. They can handle high pressure and temperature conditions, and are suitable for gas, liquid, or even corrosive media, depending on the materials used. With minimal pressure drop and fast on-off control, ball valves are widely used in industries like oil and gas, water treatment, chemical processing, and general plumbing. They come in various types such as two-way, three-way, floating, and trunnion-mounted, and can be operated manually, pneumatically, or electrically.

- 1

- 2