مقدمه

شیرهای کنترلیشیرهای یکطرفه که به عنوان شیرهای یکطرفه یا شیرهای یکطرفه نیز شناخته میشوند، اجزای ضروری در سیستمهای لولهکشی صنعتی هستند. وظیفه اصلی آنها اجازه دادن به جریان سیال در یک جهت و در عین حال جلوگیری از جریان برگشتی است که میتواند به پمپها، کمپرسورها و سایر تجهیزات آسیب برساند. این راهنما اصول کار، مواد، اندازهها، درجهبندی فشار و کاربردهای آنها را بررسی میکند تا به مهندسان و متخصصان تدارکات در تصمیمگیریهای آگاهانه کمک کند.

نحوه کار شیرهای یکطرفه

شیرهای یکطرفه بهطور خودکار عمل میکنند و برای باز و بسته شدن به فشار سیال متکی هستند:

جریان رو به جلو: هنگامی که فشار ورودی از فشار خروجی بیشتر شود، شیر باز میشود و به سیال اجازه عبور میدهد.

- جریان معکوس: در صورت وقوع جریان معکوس، شیر به دلیل نیروی جاذبه، نیروی فنر یا فشار معکوس فوراً بسته میشود و سیستم را آببندی میکند.

انواع و مکانیسمهای رایج

۱. شیر یکطرفه نوسانی: از یک دیسک لولایی استفاده میکند که با جریان باز میشود و با معکوس شدن جریان بسته میشود. برای مایعات با سرعت پایین ایدهآل است.

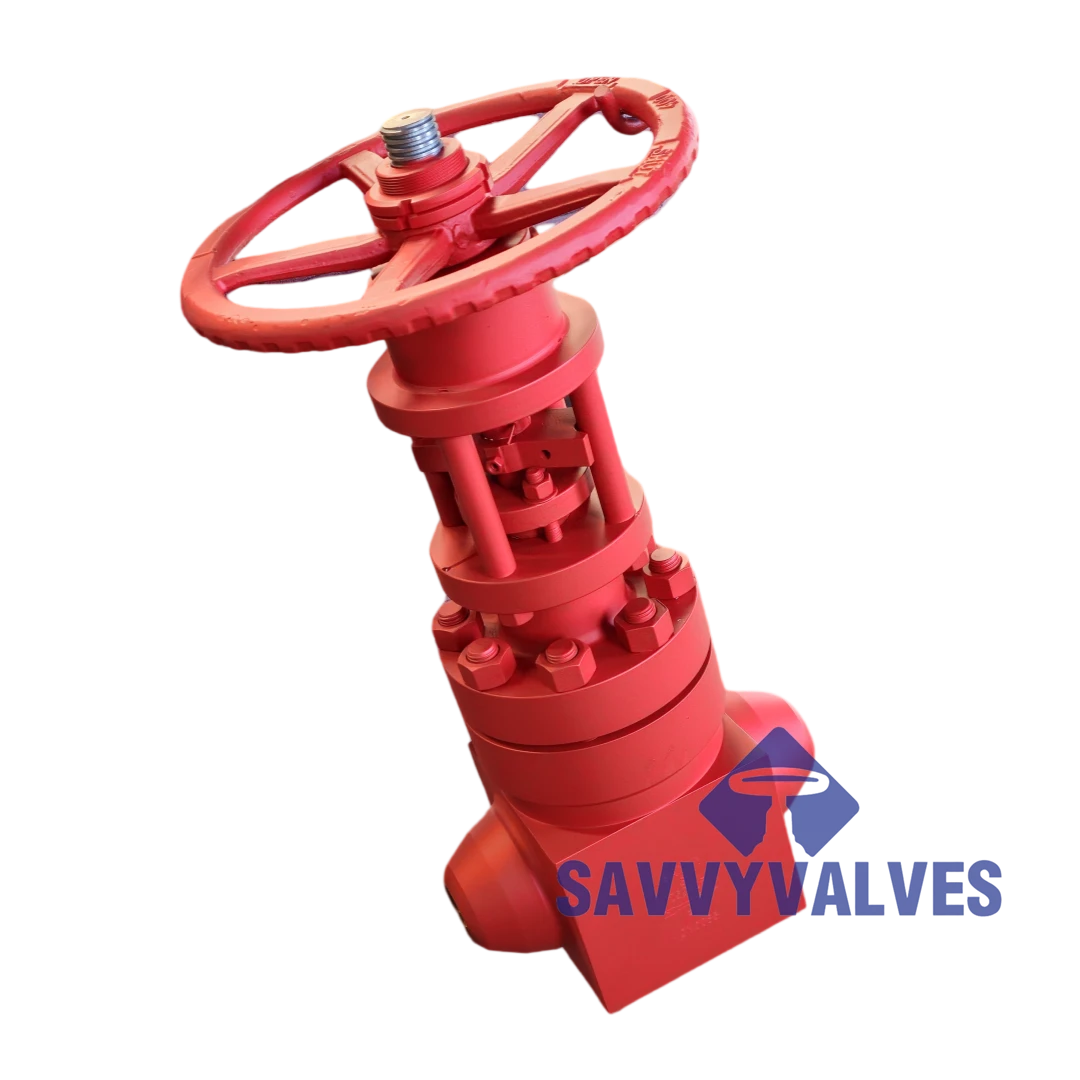

۲. شیر یکطرفه بالابرنده: یک پیستون یا ساچمه تحت فشار به صورت عمودی بالا میرود و هنگامی که جریان متوقف میشود، دوباره در جای خود قرار میگیرد. مناسب برای سیستمهای فشار بالا.

۳. شیر یکطرفه دو صفحهای: دو صفحه فنری، ضربه قوچ را کاهش میدهند و برای فضاهای تنگ، جمع و جور هستند.

۴. شیر یکطرفه ساچمه ای: یک ساچمه شناور آزاد، سیت را آب بندی می کند و اغلب در کاربردهای سیالات کوچک یا ویسکوز استفاده می شود.

معیارهای انتخاب کلید

۱. انتخاب مواد

شیرهای یکطرفه در مواد مختلفی تولید میشوند تا با محیطها و رسانههای مختلف سازگار باشند:

- چدن: برای سیستمهای آب و کمفشار مقرونبهصرفه است.

- فولاد کربنی: استحکام بالا برای کاربردهای نفت، گاز و بخار (به عنوان مثال، ASTM A216 WCB).

- فولاد ضد زنگ (304/316): مقاوم در برابر خوردگی برای مواد شیمیایی، آب دریا و فرآوری مواد غذایی.

- فولاد دوپلکس: عالی برای محیطهای دریایی و با غلظت بالای کلرید.

-PVC/PP: گزینههای سبک و مقاوم در برابر مواد شیمیایی برای سیالات اسیدی یا قلیایی.

۲. اندازه و انواع اتصال

- اندازهها: از ½ اینچ (DN15) تا 60 اینچ (DN1500) برای خطوط لوله بزرگ.

- اتصالات انتهایی:

- فلنجی: استانداردهای ANSI، DIN یا JIS برای سیستمهای فشار قوی.

- ویفر/لوگ: صرفهجویی در فضا برای نصبهای فشرده.

- جوش رزوه ای/سوکتی: در لوله کشی با قطر کوچک رایج است.

۳. رتبهبندی فشار

- فشار پایین (PN6-PN16): سیستمهای آبرسانی، تهویه مطبوع.

- فشار متوسط (PN25-PN40): پالایش نفت، فرآوری شیمیایی.

- فشار بالا (PN100-Class 2500): نیروگاهها، خطوط لوله زیر دریا.

کاربردهای صنعتی

شیرهای یکطرفه در صنایعی که جلوگیری از جریان برگشتی حیاتی است، بسیار مهم هستند:

۱. آب و فاضلاب

- خطوط تخلیه پمپ: از برگشت جریان هنگام خاموش شدن پمپ ها جلوگیری می کند.

- شبکههای آب شهری: جریان یکطرفه را در سیستمهای توزیع تضمین میکند.

۲. نفت و گاز

- انتقال از طریق خط لوله: محافظت در برابر جریان معکوس در خطوط نفت خام و گاز.

- پالایشگاهها: در واحدهای جداسازی و ایستگاههای کمپرسور استفاده میشود.

۳. تولید برق

- سیستمهای تغذیه دیگ بخار: جریان برگشتی بخار/آب را در نیروگاههای حرارتی متوقف میکند.

- مدارهای خنککننده: جهت جریان را در نیروگاههای هستهای یا زغالسنگی حفظ میکند.

۴. شیمیایی و دریایی

- کار با اسید/قلیا: شیرهای مقاوم در برابر خوردگی برای محیطهای خورنده.

- کارخانههای نمکزدایی: از برگشت آب دریا در سیستمهای RO جلوگیری میکند.

تعمیر و نگهداری و عیبیابی

- مرتباً بازرسی کنید: فرسودگی، تجمع زباله یا نشتی آببند را بررسی کنید.

- عملکرد آزمایشی: از بسته شدن سریع برای جلوگیری از ضربه قوچ اطمینان حاصل کنید.

- قطعات فرسوده را تعویض کنید: دیسکها، فنرها و نشیمنگاهها به مرور زمان فرسوده میشوند.

چرا شیرهای کنترلی ما را انتخاب کنیم؟

- عملکرد اثباتشده جهانی: مورد استفاده در میادین نفتی ADNOC، کارخانههای نمکزدایی امارات متحده عربی و پروژههای آب اروپا.

- راهکارهای سفارشی: مواد، اندازهها و رتبهبندیهای فشار سفارشی.

- کیفیت تایید شده: مطابق با استانداردهای API 594، ISO 9001 و دستورالعمل PED.

نتیجهگیری

شیرهای یکطرفه برای کنترل ایمن و کارآمد سیال ضروری هستند. درک طراحی، مواد و محدودیتهای عملیاتی آنها، عملکرد بهینه را در هر صنعتی تضمین میکند. برای پشتیبانی فنی یا انتخاب محصول، همین امروز با تیم مهندسی ما تماس بگیرید.

(تعداد کلمات: حدود ۸۰۰)

توجه: این راهنما عمق فنی را با خوانایی متعادل میکند و آن را هم برای مهندسان و هم برای متخصصان تدارکات مناسب میسازد. در صورت نیاز، تأکیدات (مثلاً مطالعات موردی، نمودارهای CAD) را تنظیم کنید.