شیرهای حرارتی

-

اندازه: ۱۴ اینچ

RATING: 150LB

بدنه: ASTM A217 C5

دیسک: ASTM A217 C5

یوغ توسعه یافته: ASTM A182 F5

STEM: SS416

نشیمنگاه: ASTM A182 F5 قابل تعویض

SEAL: SS316+GRAPHITE LAMINATED

فعالسازی: واحد دنده

-

شیر دروازهای دیسکی موازی Savvy مدل F91 سایز 16 اینچ و وزن 1500 پوند برای کاربردهای حرارتی/دمای بالاعکسها مشخصات را به شرح زیر نشان میدهند

اندازه: ۱۶ اینچ

رتبهبندی: ۱۵۰۰ پوند

بدنه: ASTM A182 F91

دیسک: ASTM A182 F91

فنر: اینکونل X-750

STEM: ASTM A182 F91

نشیمنگاه: ASTM A182 F91 قابل تعویض.

فعالسازی: واحد دنده

-

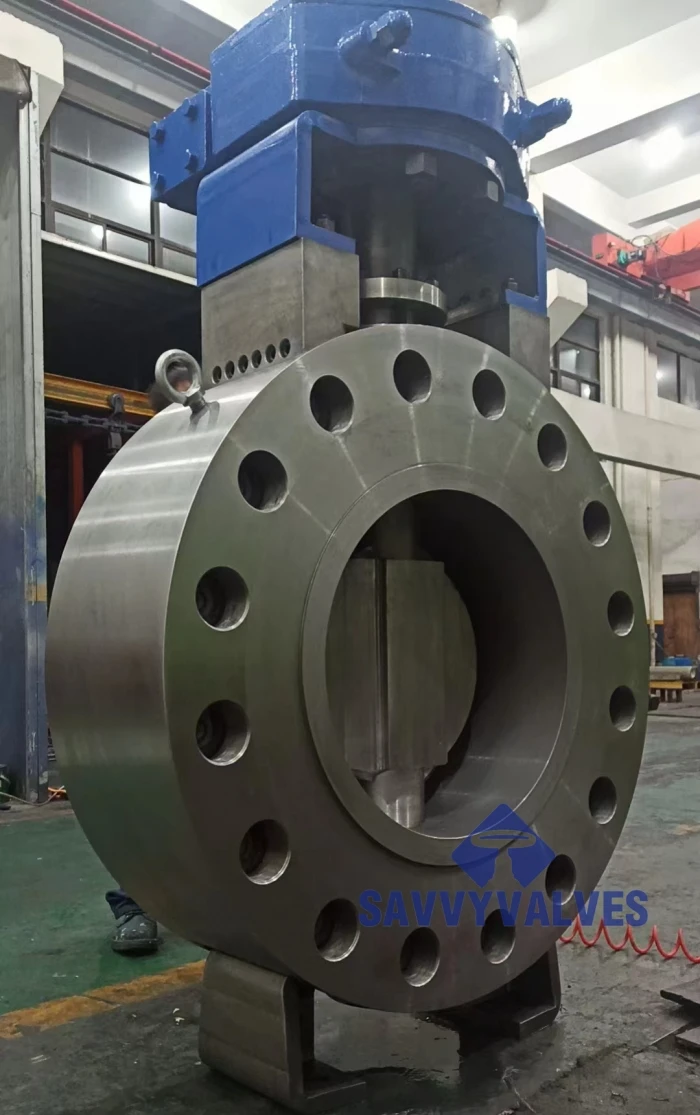

اندازه: DN800

رتبهبندی: PN25

بدنه: سی اس

دیسک: CF8

یوغ توسعه یافته: ASTM A182 F5

STEM: SS416

نشیمنگاه: ASTM A182 F5 قابل تعویض

SEAL: SS316+GRAPHITE LAMINATED

فعالسازی: واحد دنده

-

اندازه: ۳ اینچ

رتبه بندی: ۱۵۰۰ پوند

ساختار: کلاهک پیچ و مهره ای، سیستم عامل و Y

بدنه و کلاهک: ASTM A217 WC9

دیسک: ASTM A217 WC9 + STELLITE 6

STEM: ASTM A182 F316

نشیمنگاه: ASTM A182 F22 + STELLITE 6

فعالسازی: محرک الکتریکی

-

اندازه: ۲۶ اینچ

رتبهبندی: ۱۵۰۰ پوند

بدنه: ASTM A105N

دیسک: ASTM A182 F316

یوغ توسعه یافته: ASTM A182 F5

STEM: SS416

نشیمنگاه: ASTM A182 F316

SEAL: SS316+GRAPHITE LAMINATED

فعالسازی: واحد دنده

-

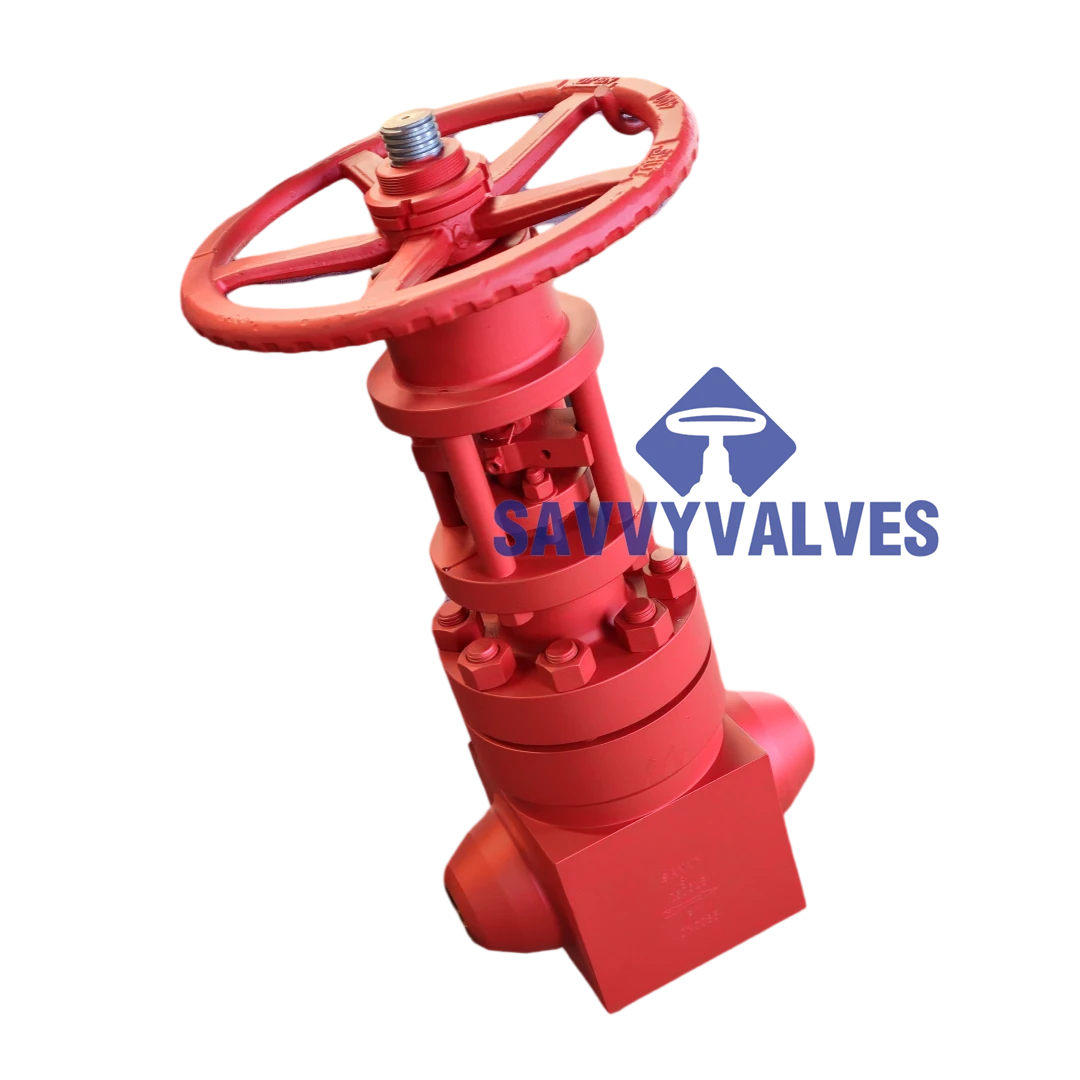

مختصر:

اندازه: ۳ اینچ

امتیاز: 2500 پوند

مواد:

بدنه و کاپوت ASTM A182 F11

دیسک ASTM A182 F11+stellite 6

ساقه ASTM A182 F6A

صندلی بدنه روکش دار Stellite 6

اپراتور: چرخ دستی

پایان: وزن بدن طبق ANSI B16.25

Thermal duty valves are specially designed valves used in systems where extreme temperature control is required, typically in thermal oil, steam, or high-temperature gas applications. These valves are engineered to withstand high heat without deforming or losing performance, making them essential in industrial settings like power generation, petrochemical processing, and heat transfer systems. Their bodies and internal components are typically made from heat-resistant alloys or stainless steel and include features like extended bonnets to protect packing materials from heat exposure. Thermal duty valves can be either manual or automated and often include insulation options to retain heat and improve energy efficiency. Some are designed to open or close automatically when a certain temperature threshold is reached, using thermal actuators or sensors. These valves help ensure safe and efficient system operation by controlling flow under thermal stress conditions, reducing the risk of system failure. Their design focuses on durability, reliability, and precision, even in fluctuating or extreme temperature environments.