Uw Grill Grills Hout Pelletgrill

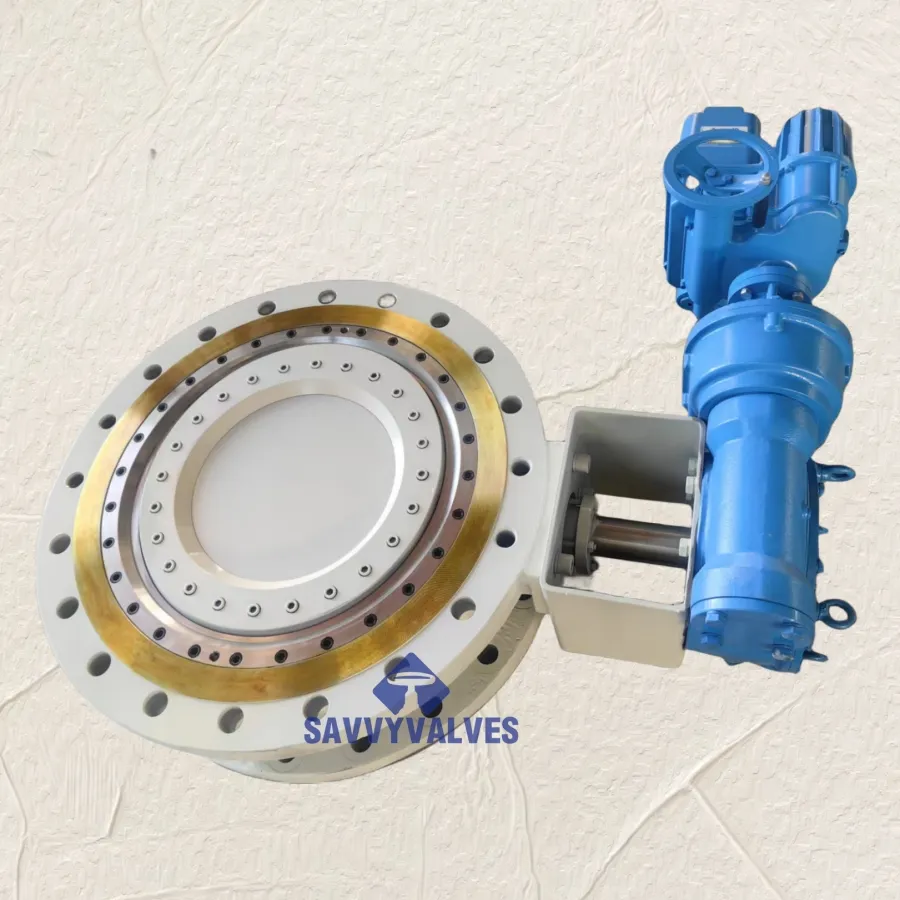

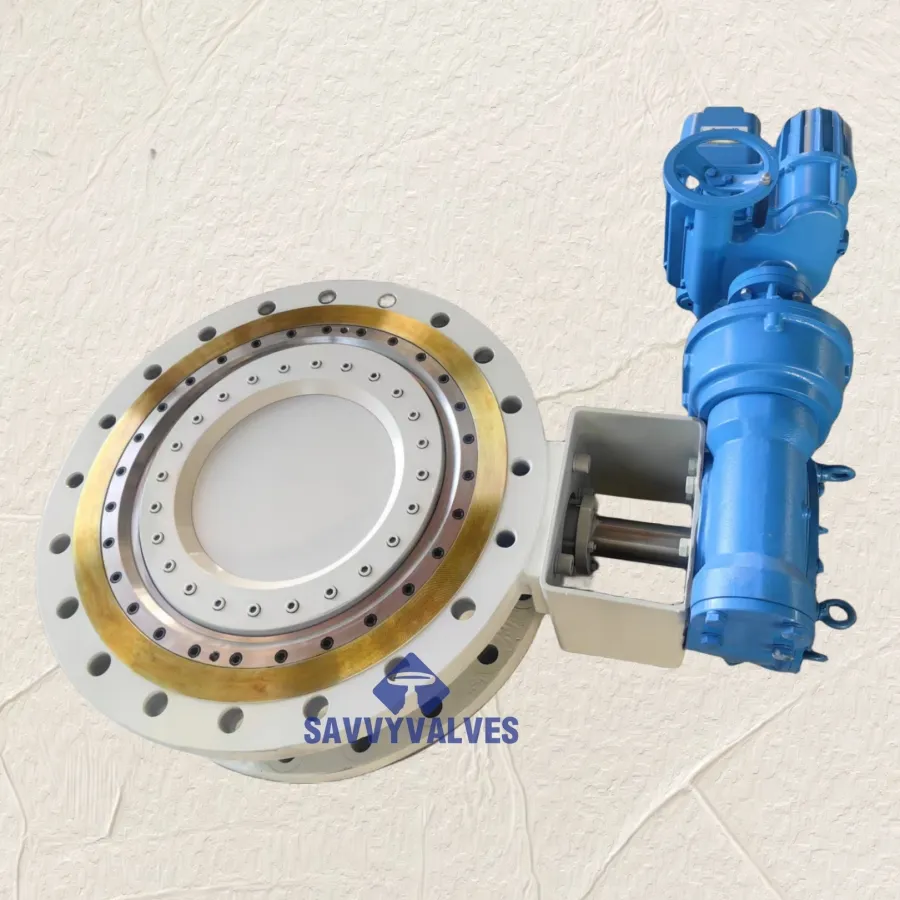

PHOTOS SHOWS SPECIFICATIONS AS BELOWS

SIZE: 20″

RATING: 150LB

BODY: WCB

DISC: CF8

YOKE: ASTM A105

STEM: SS416

SEAT: STELLITED 6 HF

SEAL: SS316+GRAPHITE LAMINATED

ACTUATION: ELECTRIC ACTUATED

GENERAL DESIGNED SPECIFICATION

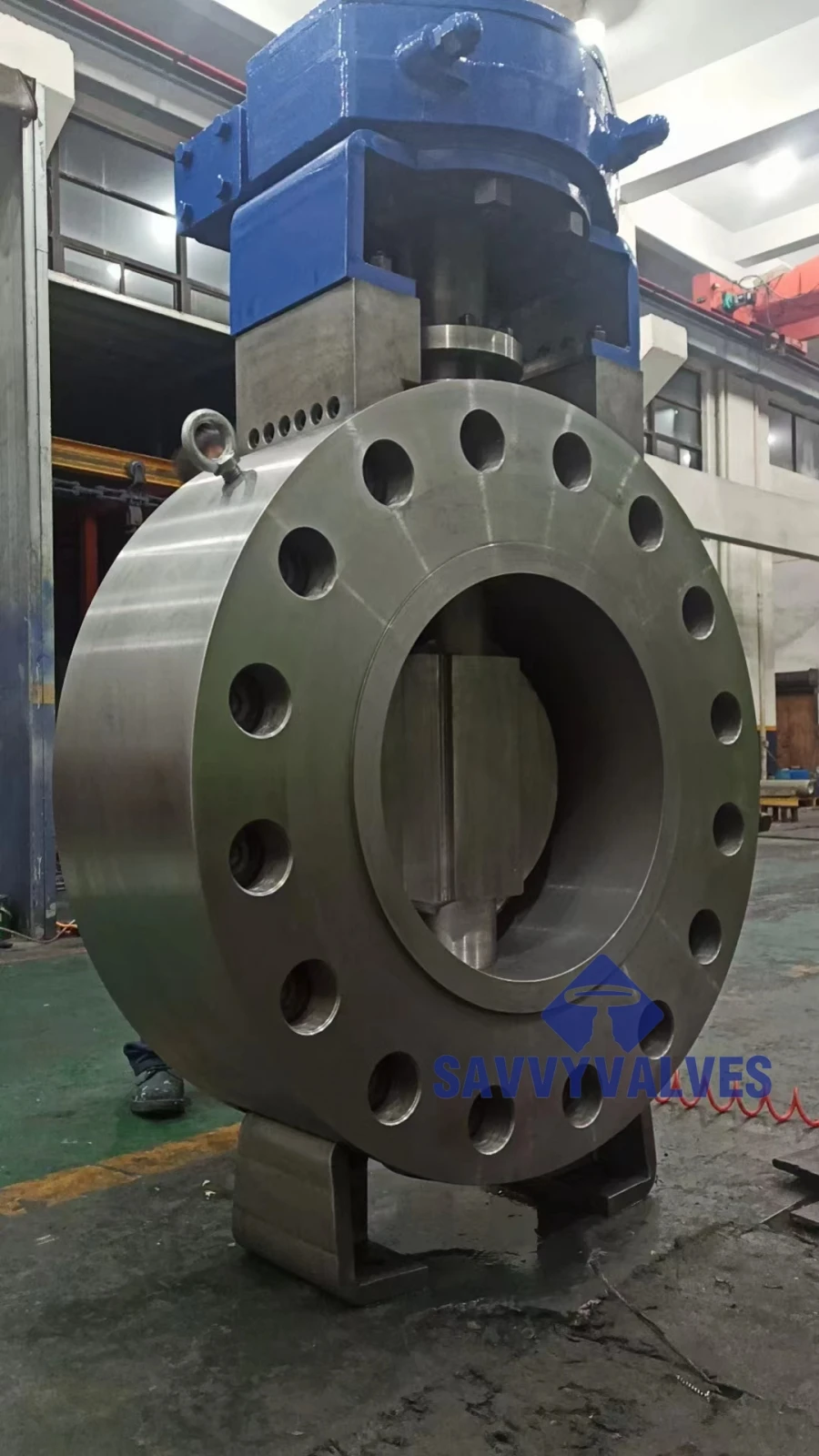

Afmetingen: 2″~144″.

Drukclassificatie: 150LB~4500LB

Design Temperature: MAX. 800℃.

General applications: STEAM.

Design & Manufacture: API 609, EN 593 are basic, ASME B16.34 ,other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: ASME B16.25, EN 1092, JIS 5K-20K. RF, RTJ are available.

Safety design: anti-blow out stem.thermal plate.

TYPISCHE MATERIAALLIJST

BODY: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

DISC: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

EXTENDED YOKE: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K500, H-276

ZETEL: STELLITE NO.6 HF

SEAL: SS316+GRAPHITE LAMINATED

BEDIENER: TANDWIELEENHEID

ANDERE SPECIALE MATERIALEN ZIJN BESCHIKBAAR VOOR AANPASSING.

TEST EN INSPECTIE

Inspectie- en goedkeuringsnorm: API598, API6D.

KWALITEITSCONTROLE

100% Chemische analyse en mechanische test met grondstoffen van elk hittenummer.

100% DPT-test met de gietstukken, gedeeltelijk MT- of UT-test, RT is indien nodig altijd beschikbaar.

100% hydraulische test met de behuizing en afdichting en lagedrukluchttest.

GARANTIE

SAVVY VALVES hebben een levensduur van minimaal 12 maanden. Indien nodig worden gratis reserveonderdelen en onderhoudsinstructies verstrekt.

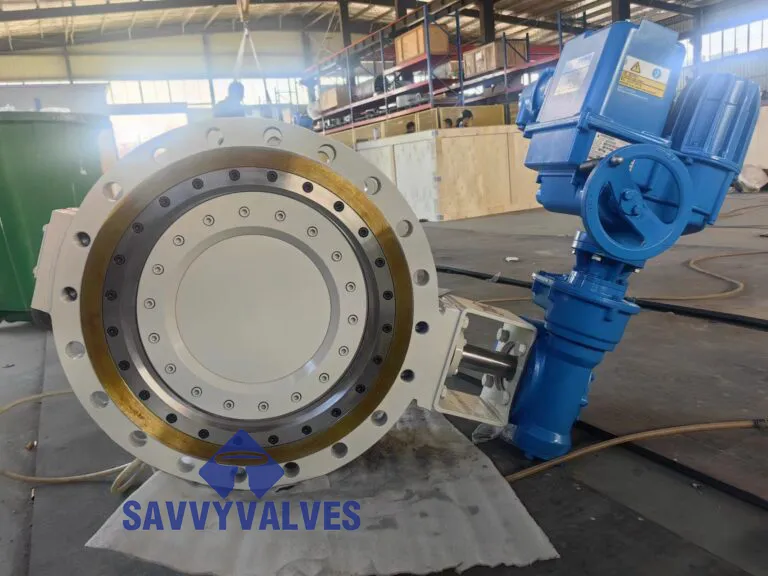

Triple offset butterfly valves gear operated are ideal for precise flow control in high-pressure and high-temperature industrial applications. The triple offset design ensures that the disc moves away from the seat during opening and closing, eliminating friction and minimizing wear, which leads to a reliable, bubble-tight shutoff. The gear operation provides mechanical advantage, allowing smooth and accurate manual control even in large valve sizes or under demanding conditions. This setup is particularly valuable in industries like power generation, oil and gas, and petrochemical processing, where operational reliability is critical. The robust construction and metal-to-metal sealing enable the valve to withstand thermal expansion, pressure surges, and aggressive media. Thanks to the gear-operated mechanism, operators benefit from enhanced torque control, reduced effort, and improved safety, making these valves a dependable solution for challenging flow control environments.

Als u geïnteresseerd bent in onze producten, kunt u hier uw gegevens achterlaten. Wij nemen dan binnenkort contact met u op.