Kayu Panggangan Grill Anda Pemanggang Pelet

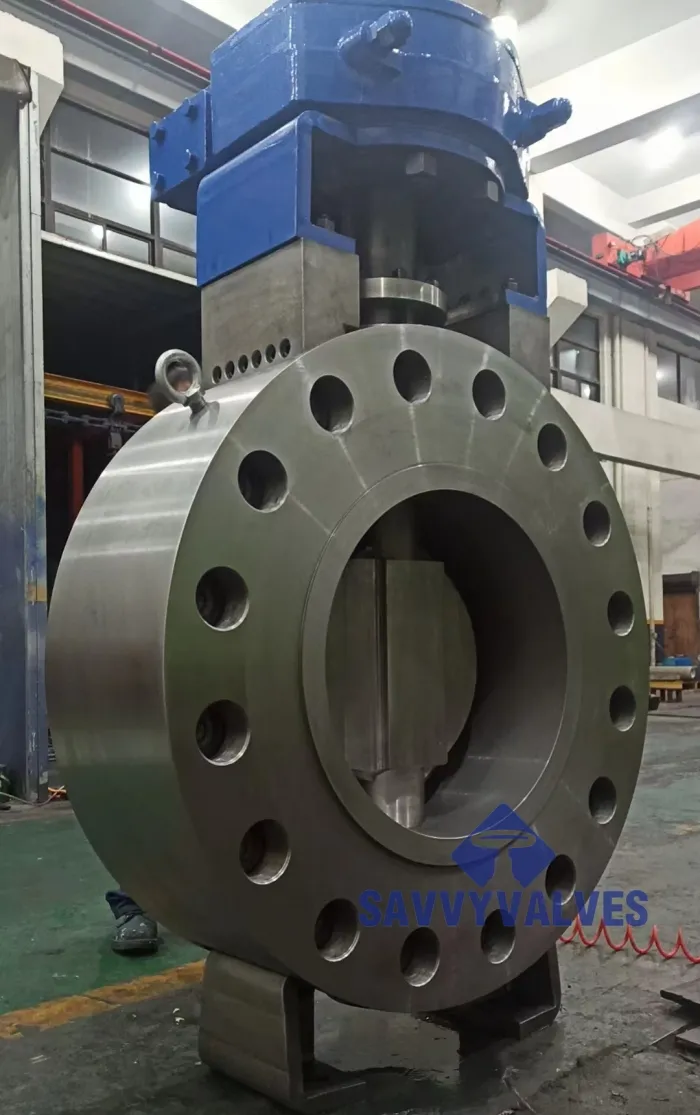

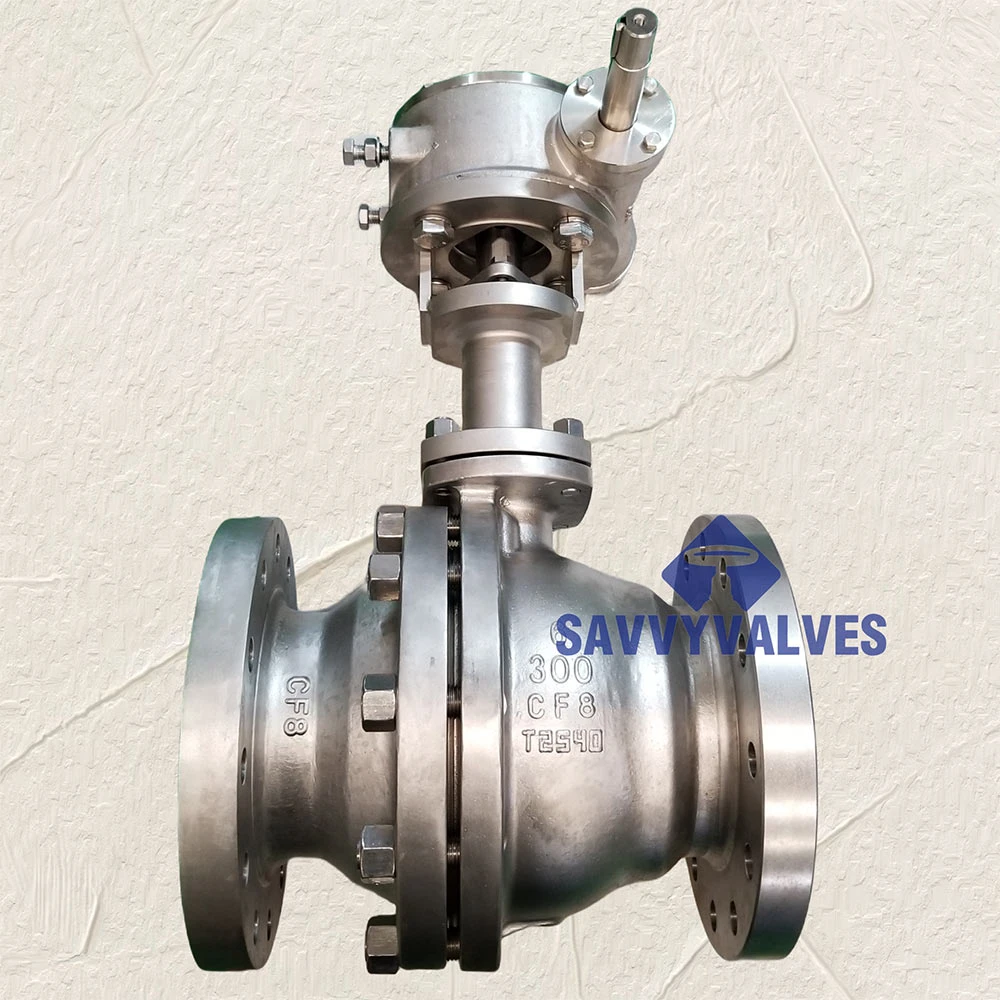

SAIZ: 26″

PENILAIAN: 1500LB

BADAN: ASTM A105N

CAKERA: ASTM A182 F316

YOKE EXTENDED: ASTM A182 F5

STEM: SS416

KEDUDUKAN: ASTM A182 F316

SEAL: SS316+GRAPHITE LAMINATED

PENGAKUAN: UNIT GEAR

SPESIFIKASI UMUM YANG DIREKA

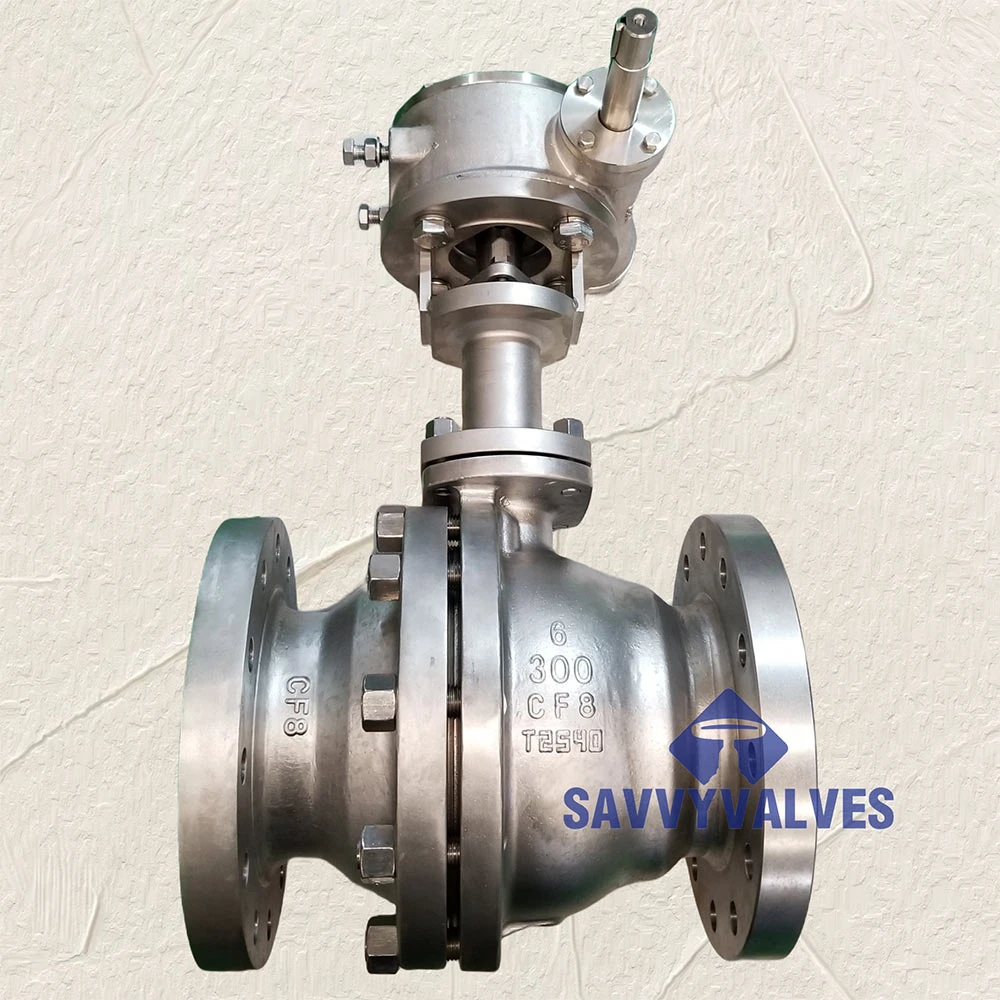

Saiz: 2″~144″.

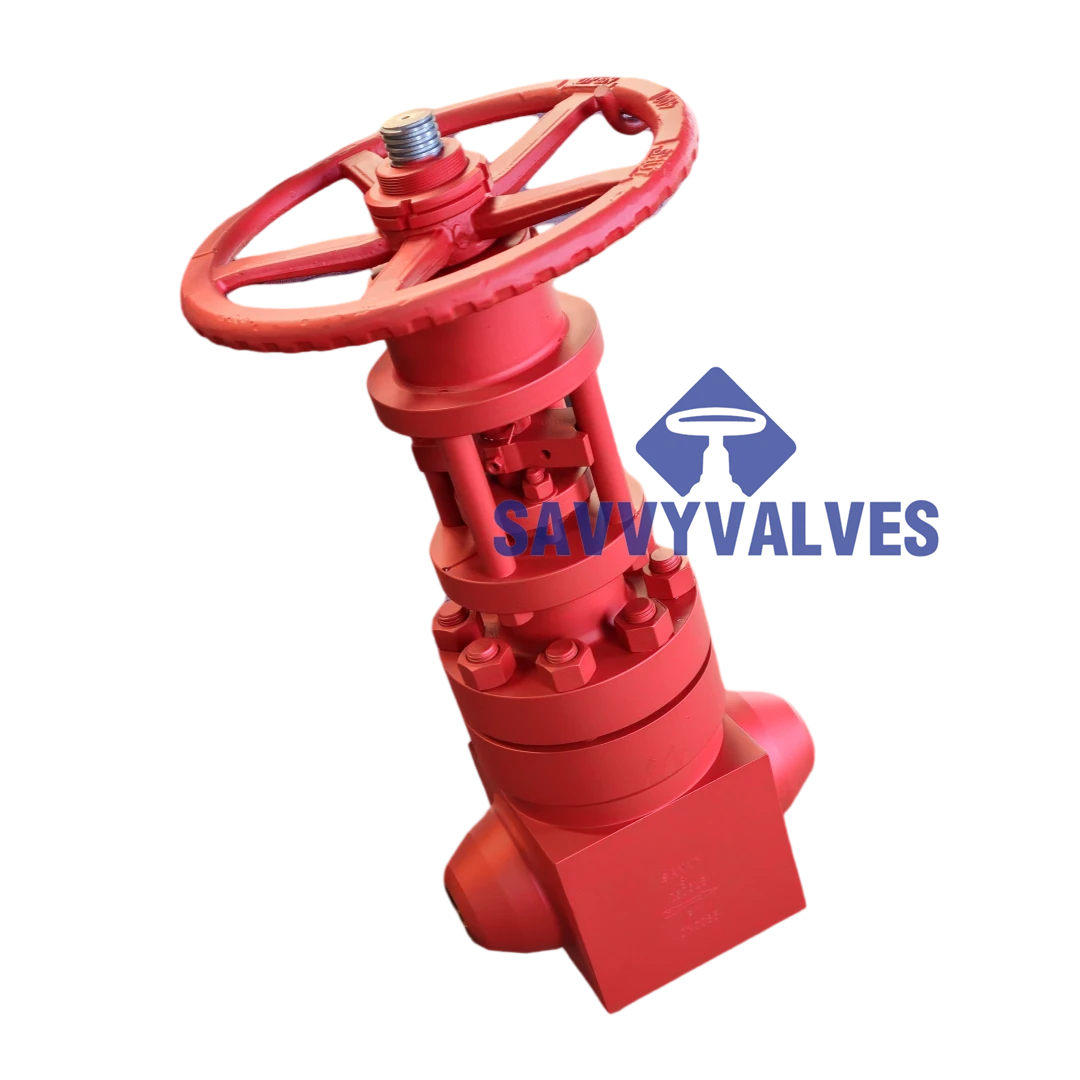

Penilaian Tekanan: 150LB~4500LB

Design Temperature: MAX. 800℃.

General applications: STEAM.

Design & Manufacture: API 609, EN 593 are basic, ASME B16.34 ,other norms could be used according to orders.

F TO F dimensions: API 609, ASME B16.10,BS EN 558

Connection: ASME B16.25, EN 1092, JIS 5K-20K. RF, RTJ are available.

Safety design: anti-blow out stem.thermal plate.

SENARAI BAHAN TYPICAL

BODY: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

DISC: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

EXTENDED YOKE: ASTM A216 WCB/WCC, ASTM A217 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

ASTM A105, F11, F22, C5, F91, ASTM A182 F304/F304L/F316/F316L/F6A/F11/F22/F91/F51/F53/F55, A694 F60, C83600/C95400/C95800, MONEL K400/K500, H-276, INCONEL 625/718

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K400, MONEL K400

KEDUDUKAN: STELLITE NO.6 HF

SEAL: SS316+GRAPHITE LAMINATED

OPERATOR: UNIT GEAR

BAHAN KHAS LAIN ADA UNTUK DISESUAIKAN.

UJIAN DAN PEMERIKSAAN

Pemeriksaan dan norma kelulusan: API598, API6D.

KAWALAN KUALITI

100% Analisis kimia dan ujian mekanikal dengan bahan mentah setiap nombor haba.

Ujian DPT 100% dengan tuangan, sebahagiannya ujian MT atau UT, RT sentiasa tersedia jika diperlukan.

Ujian hidraulik 100% dengan shell dan meterai dan ujian udara tekanan rendah.

JAMINAN

SAVVY VALVES komited untuk menyampaikan kualiti produk yang luar biasa dan perkhidmatan selepas jualan tanpa bimbang. Injap kami dijamin memberikan hayat perkhidmatan minimum selama 12 bulan, di mana kami akan membekalkan semua alat ganti yang diperlukan dan arahan penyelenggaraan terperinci secara percuma. Dalam tempoh jaminan, jika sebarang kerosakan bukan disebabkan oleh manusia berlaku, kami akan menggantikan komponen tanpa kos dan menyediakan sokongan teknikal profesional. Selepas jaminan tamat, pelanggan hanya perlu membayar kos alat ganti, sementara masih mendapat manfaat daripada perkhidmatan penyelenggaraan berdiskaun. Matlamat kami adalah untuk membantu pelanggan mengurangkan kos operasi dan meningkatkan kecekapan pengeluaran melalui kualiti yang boleh dipercayai dan sokongan selepas jualan yang komprehensif. Sama ada untuk pertanyaan teknikal atau keperluan penyelenggaraan, pasukan pakar kami akan bertindak balas dengan segera untuk memastikan sistem injap anda mengekalkan prestasi optimum pada setiap masa.

The SAVVY high temperature triple offset butterfly valve is built for demanding thermal systems requiring zero leakage, precise control, and long-term durability. Its triple offset design eliminates friction between the disc and seat during operation, which reduces wear and ensures a tight metal-to-metal seal—ideal for high-temperature steam, gas, or thermal oil applications. Forged steel construction enhances strength and resistance to thermal stress, making it suitable for power plants, petrochemical units, and industrial furnaces. This valve excels in systems with frequent temperature fluctuations, maintaining reliable performance without distortion or leakage. It also supports automated actuation for remote or process-integrated control. Overall, the SAVVY valve is a trusted solution for thermal duty pipelines where tight shut-off, longevity, and resistance to extreme heat are critical.

Jika anda berminat dengan produk kami, anda boleh memilih untuk meninggalkan maklumat anda di sini, dan kami akan menghubungi anda sebentar lagi.