1. Gambaran keseluruhan

A gate valve is a linear-motion valve that controls flow by raising or lowering a gate. Key features include:

- Full-bore design (unobstructed flow path, minimal pressure drop)

- Bidirectional sealing (can block flow from either direction)

- High-pressure resistance (forged steel valves up to PN420/Class 2500)

- Wide applicability (from cryogenic -196℃ to high-temperature 550℃)

2. Komponen Utama

| Komponen | Penerangan |

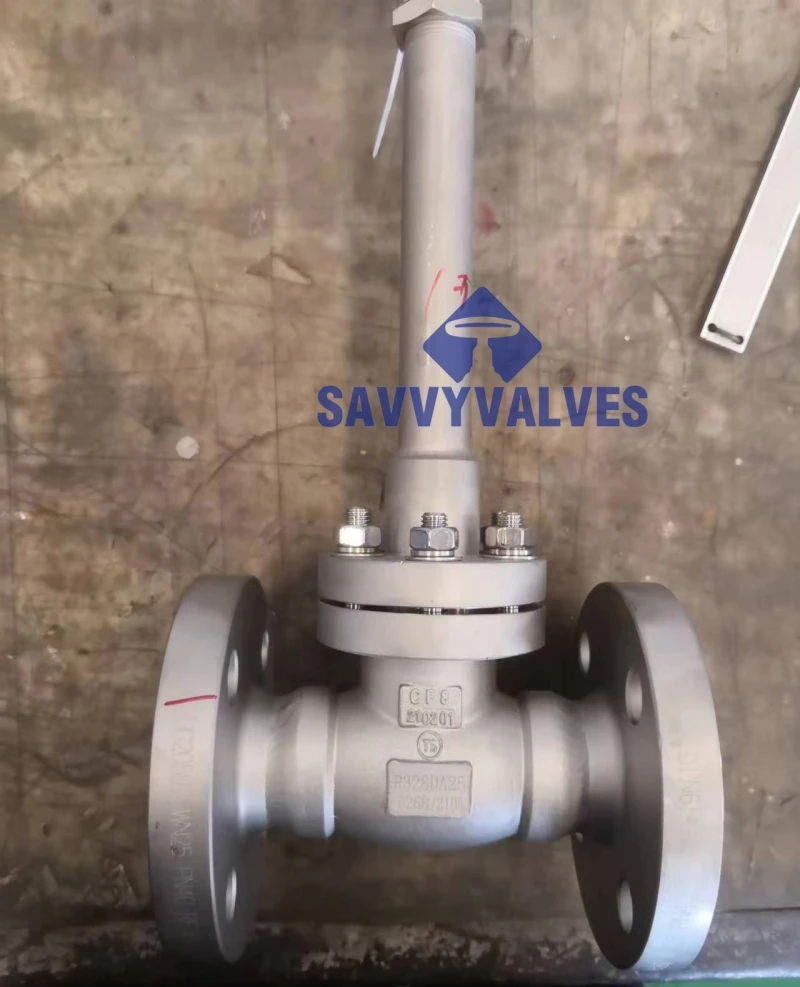

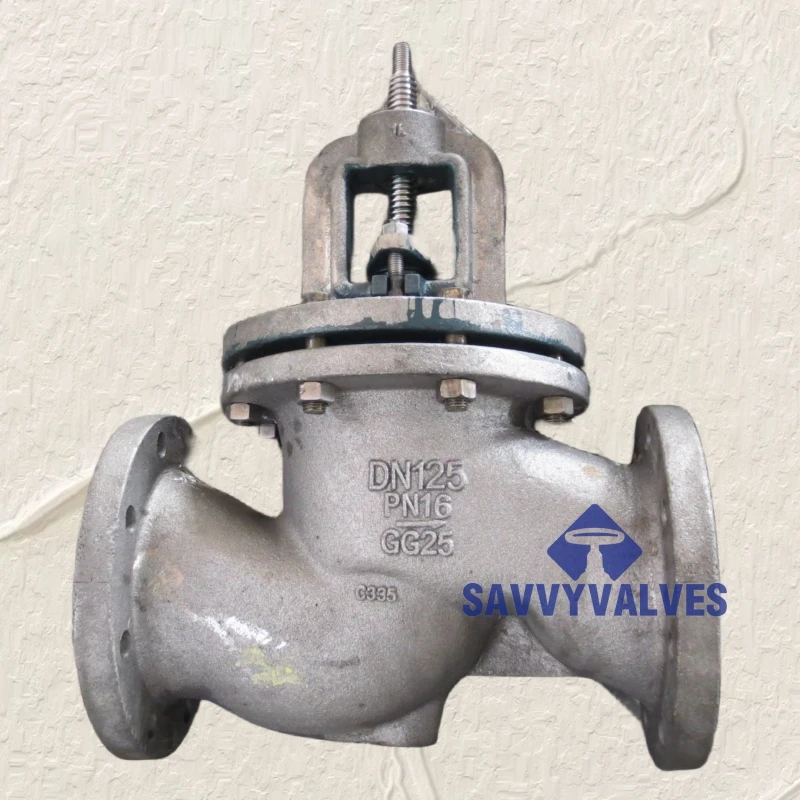

| Badan | Cast (WCB/CF8) or forged (A105/F22); connections: flanged/buttweld/threaded |

| Gate | Wedge/parallel design; materials: SS (304/316), alloy steel (410), Monel |

| tempat duduk | Stellite hard-faced or PTFE soft seal |

| Batang | Rising/non-rising stem; 17-4PH material; graphite packing with SS spring |

| Sealing Mechanism | Self-sealing/forced sealing; bellows seal for high-pressure applications |

| Penggerakan | Handwheel/gear-operated/electric/pneumatic (ISO 5211 compliant) |

3. Jenis

(1) By Gate Design

- Wedge Gate Valve

- Single gate: For standard temp/pressure

- Double gate: Auto-wear compensation for high temp/pressure

- Flexible gate: Prevents thermal deformation

- Parallel Slide Gate Valve

- Dual gates + spring load, ideal for steam systems

- Knife gate: Designed for slurries/sludge

(2) By Stem Movement

- Rising Stem: Stem moves vertically (visual position indication)

- Non-Rising Stem: Stem rotates only (space-saving)

(3) Jenis Khas

- Slab Gate Valve: For pipelines (API 6D)

- Cryogenic Gate Valve: -196℃ treatment (LNG applications)

- Power Plant Gate Valve: Cr-Mo steel (P91/P92), high temp/pressure resistant

4. Spesifikasi

| Parameter | Julat | Nota |

| Saiz (DN) | DN15~DN1200 | Reka bentuk tersuai untuk saiz yang lebih besar |

| Penilaian Tekanan | PN10~PN420 (ANSI 150~2500) | Forged bodies up to Class 2500 |

| Suhu | -196℃~550℃ | Cr-Mo steel for high temp |

| Media | Water/steam/oil/acids | Hastelloy trim for corrosive media |

| Kelas Kebocoran | ANSI Class IV (metal seal) | Soft seal achieves Class VI |

| Operation Time | 30-60 sec for large electric valves | Gear operation: slower but easier |

5. Aplikasi

① Minyak & Gas

- Pipeline isolation (API 6D)

- Wellhead equipment (sour service carbon steel valves)

② Bahan kimia

- Corrosive media (Hastelloy valves)

- High-pressure reactors (forged steel valves)

③ Kuasa

- Boiler feedwater (high-temp Cr-Mo valves)

- Steam systems (parallel double-disc design)

④ Rawatan Air

- Municipal supply (full-bore epoxy-coated)

- Wastewater (knife gate for clog prevention)

⑤ Khusus

- LNG cryogenic storage (austenitic SS valves)

- Ship ballast water (bronze for seawater resistance)

6. Panduan Pemilihan

| Permohonan | Jenis Disyorkan |

| Air/gas (PN16) | Cast iron wedge gate + EPDM seal |

| High-pressure steam (PN100) | Forged parallel slide + Stellite |

| Corrosive media | Lined/Hastelloy trim |

| Cryogenic LNG (-196℃) | Cryo-treated austenitic SS |

| Slurries/solids | Knife gate (with scraper function) |

7. Kebaikan & Keburukan

✔ Kelebihan

- Negligible flow resistance (full bore = pipe ID)

- Bidirectional sealing (no flow direction limitation)

- Superior high-pressure/temperature resistance

✖ Had

- Slow operation (multi-turn actuation)

- Unsuitable for throttling (gate erosion risk)

- Large installation height (especially rising stem)

8. Piawaian

- API 600: Petroleum gate valves

- API 603: Corrosion-resistant flanged valves

- ASME B16.34: Penarafan tekanan-suhu

- ISO 10434: Bolted bonnet valves for petroleum

9. Penyelenggaraan

- Lubricate stem threads quarterly

- Annual seal tests for high-pressure valves

- Bellows seals recommended for steam systems

Kesimpulan

Gate valves excel in full-bore, high-pressure, and bidirectional sealing applications, making them ideal for critical isolation services. Proper selection based on media properties (corrosion/temperature/solids) and operation frequency is essential. For power plants and petrochemical facilities, API-compliant forged steel gate valves ensure long-term reliability.