Kayu Panggangan Grill Anda Pemanggang Pelet

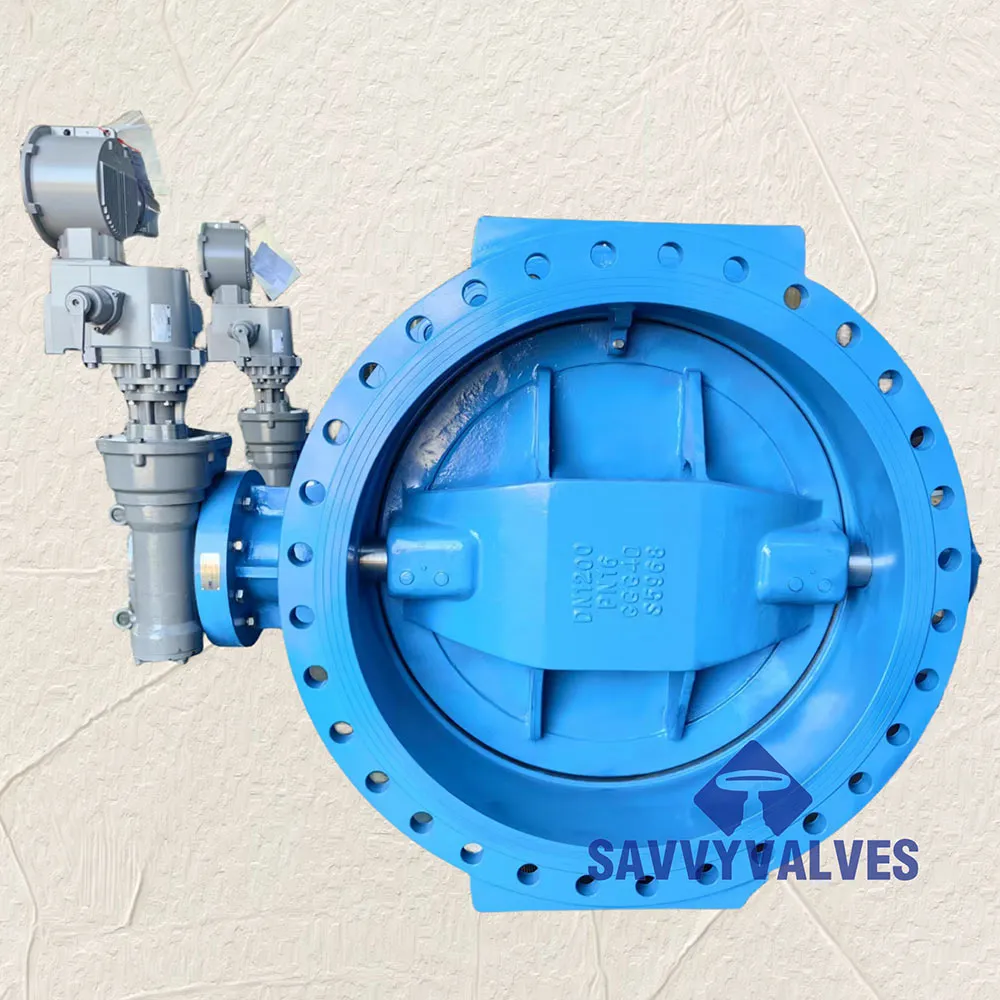

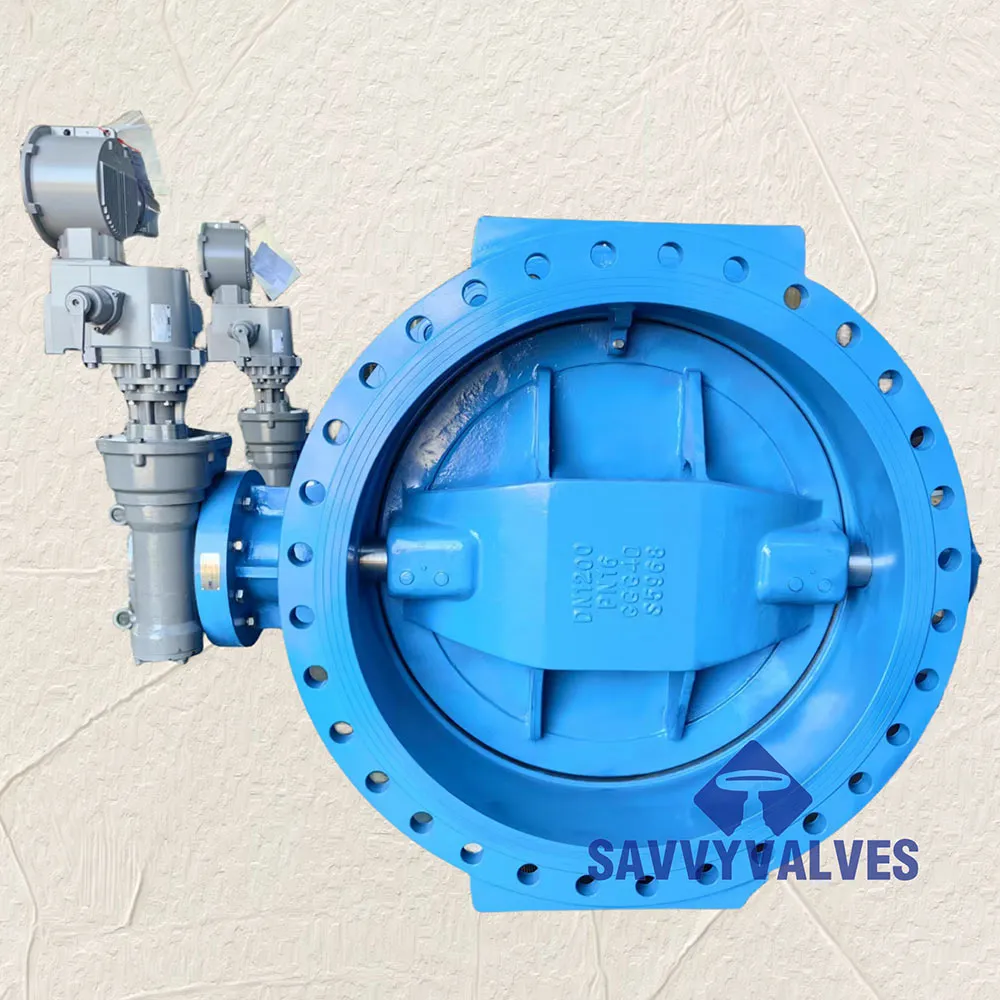

GAMBAR MENUNJUKKAN SPESIFIKASI SEPERTI DI BAWAH

SAIZ: DN1200

PENILAIAN: PN16

BADAN: ASTM A536 DUCTILE IRON/ GGG50 +304SS BODY SEAT

CAKERA: ASTM A536 BESI MURAH/ GGG50

STEM: SS416

KEDUDUKAN: EPDM

PENGAKUAN: UNIT GEAR

Size: 4″~144″.

Penilaian Tekanan: 150LB, PN6, PN10, PN16, PN20, JIS 5K, JIS 10K, JIS 16K, JIS 20K.

Aplikasi umum: Air. Minyak. Gas.

Reka Bentuk & Pembuatan: API 609, BS5155, EN593 adalah asas, ASME B16.34, norma lain boleh digunakan mengikut pesanan.

Dimensi F HINGGA F: API 609, ASME B16.10, BS EN 558, BS 5155

Sambungan: ASME B16.5, EN 1092, BS 4504, ASME B16.47 ,JIS 5K-20K.

Reka bentuk keselamatan: batang anti-letupan.

SENARAI BAHAN TYPICAL

BADAN: ASTM A 126, ASTM A 395, ASTM A536 65-45-12, ASTM A351 CF8 CF8M CF3 CF3M , 4A ,5A, C95400, C95800, B62, B148 ASTM A216 WCB/WCC7, ASTM ATM WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/CONEL 760

CAKERA: ASTM A 126, ASTM A 395, ASTM A536 65-45-12, ASTM A351 CF8 CF8M CF3 CF3M , 4A ,5A, C95400, C95800, B62, B148 ASTM A216 WCB/WCC7 WC6/WC9/C5/C12/C12A/CA15, ASTM A352 LCB/LCC, A351 CF8/CF8M/CF3/CF3M, A995 4A/5A, C83600/C95400/C95800, MONEL K400/CONEL 760

STEM: A182 F6A, F304, F304L, F316, F316L, F51, F53,17-4PH, XM-19, C95400, C95800, C83600, INCONEL 625, INCONEL 718, MONEL K400, MONEL K400, MONEL K400

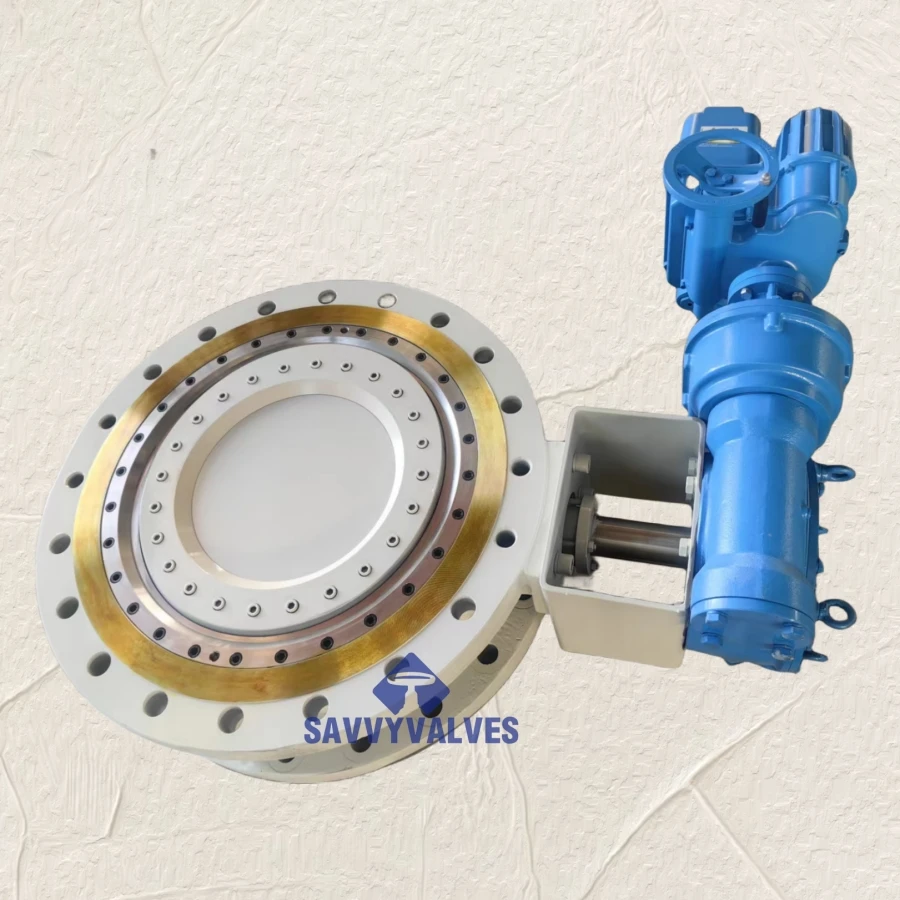

TEMPAT DUDUK: KERUSI BADAN BERMUKA KERAS KELULI STAINLESS ATAU INTEGRAL

SEAL: EPDM, NBR, VITON

OPERATOR: UNIT GEAR

BAHAN KHAS LAIN ADA UNTUK DISESUAIKAN.

UJIAN DAN PEMERIKSAAN

Pemeriksaan dan norma kelulusan: API598, API6D.

KAWALAN KUALITI

100% Analisis kimia dan ujian mekanikal dengan bahan mentah setiap nombor haba.

Ujian DPT 100% dengan tuangan, sebahagiannya ujian MT atau UT, RT sentiasa tersedia jika diperlukan.

Ujian hidraulik 100% dengan shell dan meterai dan ujian udara tekanan rendah.

JAMINAN

SAVVY VALVES menyediakan hayat perkhidmatan sekurang-kurangnya 12 bulan, alat ganti percuma dan arahan penyelenggaraan akan diberikan apabila diperlukan.

The double offset butterfly valve rubber seated design offers enhanced sealing and extended service life compared to concentric types. With its dual eccentric structure, the disc moves away from the seat during operation, reducing friction and minimizing wear on the rubber seat. This results in a tight, bubble-free seal with lower torque requirements, making it suitable for automated systems. The rubber seat ensures excellent flexibility and sealing performance, ideal for applications involving water, air, and non-corrosive fluids. The valve is widely used in industries like HVAC, water treatment, and general pipeline systems. It allows for reliable shutoff and flow control, even under moderate pressure conditions. The combination of efficient sealing, reduced maintenance needs, and compact structure makes this valve a cost-effective and dependable choice for both on-off and throttling applications.

Jika anda berminat dengan produk kami, anda boleh memilih untuk meninggalkan maklumat anda di sini, dan kami akan menghubungi anda sebentar lagi.