Full bore ball valve technology stands as a cornerstone in fluid control for industries such as oil & gas, petrochemical, water treatment, metallurgy, and energy. The API 608 2-Piece Trunnion Mounted Ball Valve Cast Steel Full Bore epitomizes modern advances in precision engineering, reliability and system efficiency. With certifications conforming to international standards (API 608, ISO 9001, ANSI, and more), these valves deliver robust performance across the globe.

This comprehensive guide provides an industry-level deep-dive into full bore ball valve design, technical parameters, use cases, comparison against alternatives (like 2 piece trunnion ball valve / trunnion mounted ball valve), and contains expert insights, real-life case studies, and transparent manufacturer data for best-in-class decision-making.

1. Industry Market Trends: Full Bore Ball Valves

- Global Market Size (2023): USD 12.4 Billion (Source: MarketsandMarkets)

- CAGR (2023-2028): 4.2% projected

- Top Applications: Oil & Gas (35%), Petrochemical (18%), Water & Wastewater (15%), Power Generation (12%), Others (20%)

- Region Distribution: Asia Pacific leads with 39% share (rapid industrialization in China & India)

- Key Drivers: Infrastructure upgrades, stricter environmental norms, rising need for zero-leakage valves, efficiency & automation

- Technology Advances: Cast steel, non-destructive testing (NDT), low-emission sealing, digital valve actuation

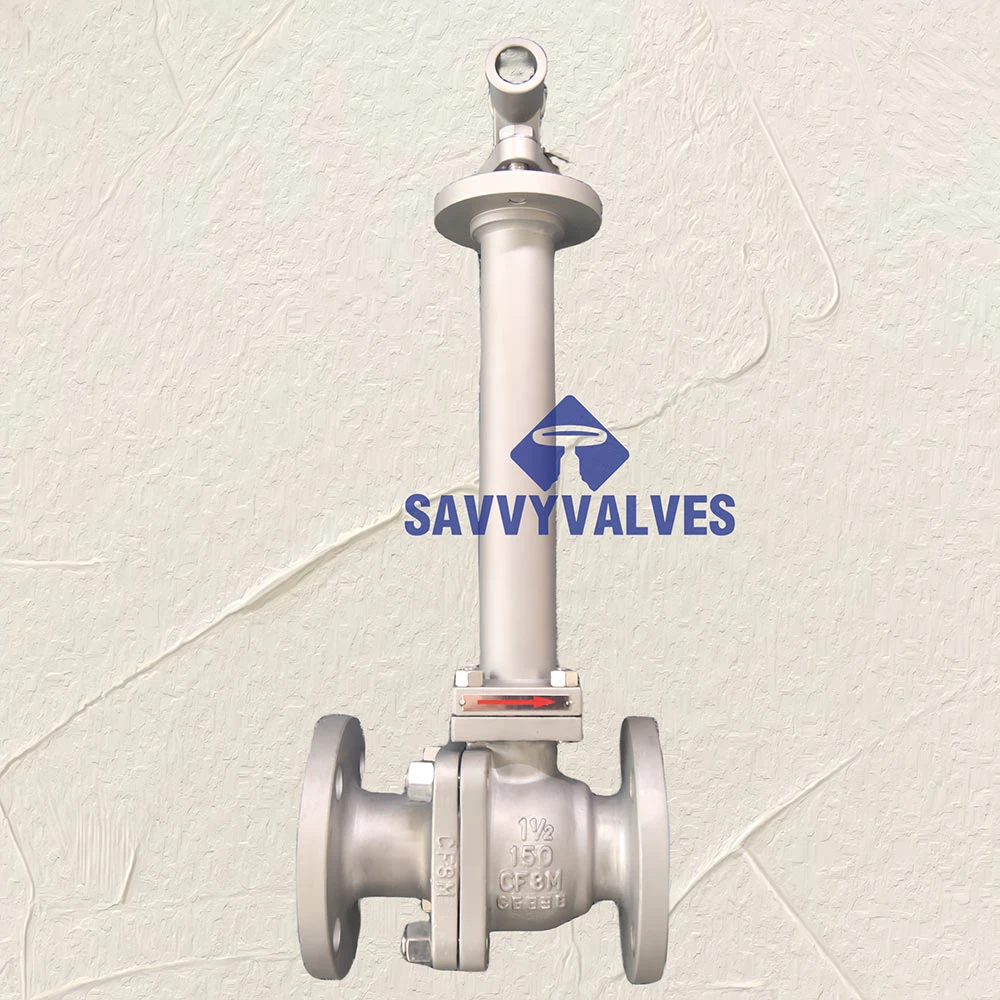

2. Technical Parameters: Full Bore Ball Valve Overview

Definition:

Full bore ball valve is a ball valve where the internal bore diameter is equal to the pipe diameter, ensuring minimal flow resistance (low pressure drop).

Main Types:

- 2 Piece Trunnion Ball Valve

- 2 Piece Trunnion Mounted Ball Valve

- Floating Ball Valve

Key Technical Specifications

| Parameter | API 608 2 Piece Trunnion Ball Valve (Full Bore) | Typical 2-Piece Floating Ball Valve |

|---|---|---|

| Bore Type | Full bore, True Bore | Full or Reduced Bore |

| Size Range | 1/2" – 24" (DN 15–600) | 1/2" – 12" (DN 15–300) |

| Pressure Rating | Class 150 – 2500 (PN16 – PN420) | Class 150 – 600 (PN16 – PN100) |

| Temperature Range | -46°C to +200°C (extended as per trim materials) | -29°C to +150°C |

| Body & Ball Material | ASTM A216 WCB, A351 CF8/CF8M (Cast/Forged Steel, Stainless Steel) | Forged Steel, Brass, Stainless Steel |

| Design Standard | API 608, API 6D, ISO 17292 | API 608, ISO 17292 |

| Testing/Certification | API 598, EN12266-1, ISO9001:2015 | API 598 |

| Lifespan | Up to 40 years (when properly maintained) | 20–30 years |

| Stem Type | Anti-blowout, Trunnion Supported | Floating |

3. Manufacturing Process Flow: Full Bore Ball Valve (API 608 2-Piece Trunnion Mounted)

Raw Material Inspection → Casting/Forging → CNC Machining → Seat/Seal Assembly → Surface Treatment → Pressure & Leak Testing → Final Inspection

- Material Selection: High-integrity cast steel or forged bars are sourced with mill test certificates, complying to ASTM A216/A351 or equivalent (API, ISO, ANSI certified).

- Casting/Forging: Components are formed under strict process rules; ultrasonic inspection ensures no porosity/defects.

- Precision CNC Machining: Bodies, balls and seats are finished to micron-level tolerances (

- Surface Hardening: Ball and seats undergo hardfacing (ENP, Stellite, Tungsten Carbide) for anti-corrosion & extended service life.

- Assembly: Automated/controlled torque assembly to ensure trunnion alignment, integrity of fire-safe seals and anti-blowout stems.

- Testing: 100% Hydrostatic and pneumatic tests per API 598 and EN12266-1 (zero leakage required). Fugitive emission testing for environmental compliance as per ISO 15848-1 and API 624.

- Inspection/Certification: Each full bore ball valve has full traceability - stamped serial number, MTC, quality dossier and often third-party witness (BV, SGS).

*Download or request our behind-the-scenes video of the API 608 2-piece trunnion ball valve production: See Our Factory

4. Comparison: API 608 2-Piece Trunnion Mounted Ball Valve vs Others

| Feature | API 608 2-Piece Trunnion Mounted Full Bore | 2 Piece Floating Ball Valve | Conventional Globe Valve |

|---|---|---|---|

| Flow Resistance | Ultra-low (Kv≈pipe) | Low to medium | High |

| Shut-Off Class | Class VI, bubble-tight, fire-safe | Class V–VI | III–IV |

| Size Availability | 1/2” to 24” (larger on request) | 1/2” to 6” | Up to 60” |

| Fugitive Emission Control | API 624, ISO 15848 certified | Limited | Limited |

| Seat Arrangement | Double block & bleed, spring energized | Bi-directional seat | Metal/Soft |

| Operating Torque | Low (actuator ready) | Medium (manual/actuated) | High |

| Maintenance Frequency | Minimal (top-entry designs) | Medium | High |

| Weight | Medium (compact for its rating) | Lightweight | Heavy |

| Typical Industries | Oil & Gas, Petrochemical, Power, Water, Steel | General utility, HVAC | Refining, Power |

5. Product Specification Charts

Core Specifications (API 608 2 Piece Trunnion Mounted)

- Size: 2” – 24” (larger available on request)

- Pressure Ratings: ASME Class 150–2500

- Body: ASTM A216 WCB / A351 CF8M

- Ball/Seats: One-piece, trunnion supported / TFM, PTFE, PEEK, ENP/TC/Cr plated

- Sealing: Double block & bleed, firesafe, antistatic, ISO 5211 pad

- Temperature: Up to 200°C (max 425°C with special trims)

- Actuation: Gear, electric, pneumatic

- Testing: 100% API 598 / 6D

- Cert: CE, SIL 3, PED, API 6FA, ISO 15848, NACE MR0175

| Valve Size (Inch) | DN | Bore Diameter (mm) | Pressure Rating (Class) | Face-to-Face (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 2 | 50 | 50 | 150/300 | 150/216 | 21/34 |

| 4 | 100 | 100 | 150/300 | 229/305 | 54/87 |

| 8 | 200 | 200 | 150/300 | 292/403 | 110/186 |

| 12 | 300 | 300 | 150/300 | 457/502 | 234/305 |

| 24 | 600 | 600 | 150/300 | 610/813 | 640/850 |

6. Application Scenarios & Use Case Highlights

- Oil & Gas: Employed across upstream production, transmission pipelines and terminals. Ability to tolerate sand, H2S, CO2 (when NACE trims used), and rapidly isolate flow (ESD functions). Wellhead manifold installations use full bore ball valve to allow pigging without flow restriction.

- Petrochemical Plants: Selected for toxic/hazardous service (chlorine, ammonia, aromatic hydrocarbons); fire-safe, antistatic devices as per API 6FA demanded by clients such as Sinopec, Shell.

- Water & Wastewater: Corrosion-resistant, PFA/ENP coated trims (2 piece trunnion ball valve type) deliver top performance in desalination, raw water intake, membrane plants.

- Steel/Metallurgy: High cycle duties for blast air, cooling & slurry; durable seats extend operating life, cut maintenance downtime by >60%.

- Power Generation: Condensate, steam lines (with high-temp trim alloys up to 425°C); actuator automation supports DCS integration.

Customer Success Case

| Client | Project | Valve Spec | Result/Feedback |

|---|---|---|---|

| PDVSA (Venezuela) | Crude Oil Transmission Pipeline | API 608 2PC Trunnion, 20” CL600, A350 LF2/SS seats | Zero leakage for 4 years, on-site pigging verified. |

| EnviroPower Asia | Combined Cycle Power Plant, Malaysia | 12” CL900 Full Bore, ENP ball, TFM seat | Cycle count >190,000, zero async alarms. |

| SINOPEC | Aromatics Pipe Rack Expansion | 2"–16” CL300, All SS, Fire-safe per API 6FA | Passed ISO 15848 emission test, no seat wear at 2 yrs. |

7. Manufacturer & Vendor Comparison

| Vendor | Core Certifications | Volume (Annual, units) | Service Experience | Major Clients |

|---|---|---|---|---|

| Savvy ValveTech | API 608, ISO 9001, CE, PED, SIL, API 624 | 25,000+ | 15+ years | PDVSA, Sinopec, ArcelorMittal |

| Flowserve | API 6D, ISO 9001, PED, NACE | 30,000+ | 30+ years | Shell, BP, Total |

| Velan | API 608, API 6D, ASME, PED | 18,000 | 50+ years | Chevron, ExxonMobil |

| JC Valves | API 608, ISO 15848, ATEX | 21,000 | 40+ years | Repsol, Lukoil |

8. Customization & Engineering Options

- Materials Customization: Duplex, Inconel, Hastelloy, Monel, Titanium for corrosion-prone or high-temp conditions.

- Seat/Seal Options: Metal-metal (for abrasive slurries), soft seat (PTFE, TFM), spring-energized designs, low-emission stem packings.

- Actuation: Integral ISO 5211 mounting pads for direct gear, pneumatic, electric actuators; engineered for SIL-rated safety loops.

- Painting & Coating: FBE, Epoxy, PFA/ENP for harsh environments (exceeds ASTM B117 salt fog test 3,000h+).

- Inspection & Documentation: Full dossier: MTC, NDE reports, PMI, hydrotest certs; EN10204 3.1/3.2 as standard.

- End Connections: RF, RTJ, BW, wafer, custom integration for manifolds/skids.

9. Delivery & After-Sales Service

- Production Lead Time: Standard valves 14–28 days; custom-engineered, exotic alloys 50–70 days

- Quality Guarantee: All full bore ball valve products warrantied for 18–36 months from shipment; major trims covered for up to 5 years (subject to service conditions).

- Technical Support: 24/7 remote assistance, onsite supervision, valve maintenance contracts, lifecycle analysis programs.

- Certifications: Third-party witnessing (BV, SGS, Lloyd’s); all QA documents provided digitally and in hardcopy.

- Logistics: Secure export packaging, traceable shipment, on-site factory acceptance testing (FAT) available.

10. Professional FAQ (Technical)

Frequently Asked Questions

11. Third-Party Validation & References

- Cited by Valve World Magazine for flow, shut-off and emission performance (DOI:10.1016/S1350-4789(22)00014-3)

- Confirmed test methods per API Standards (API 608, API 598, API 624) & ISO 15848 fugitive emissions protocols.

- Industry experience from Eng-Tips Forums (Field installation, maintenance/case studies)

- Performance validation: "Advanced Flow Simulation & Lab Evaluation of Trunnion Ball Valves", Journal of Valve Engineering